Ultra Run Neon LED Strip

- Built-in Constant Current IC: Ensures stable current, no voltage drop, and uniform brightness.

- Length Options: Available in 15m, 20m, 30m, 40m, and 50m.

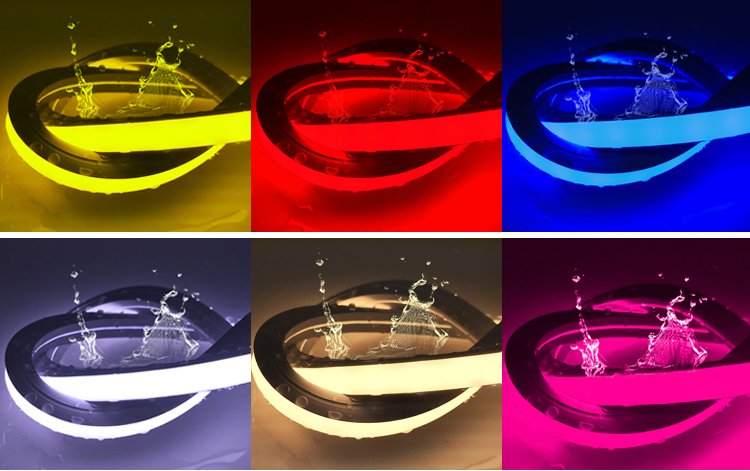

- Color Choices: Single color, dual color, multicolor, and RGB effects available, perfect for diverse lighting environments and ambiance needs.

- Waterproof: Verified waterproof performance with an IP67 rating.

- Silicone Material: Resistant to yellowing, aging, high and low temperatures, suitable for harsh indoor and outdoor environments.

- Flexible Installation: Can be easily bent and shaped, making it ideal for various design applications.

What is Ultra Run Neon LED Strip?

The Ultra Run Neon LED Strip is a flexible LED strip equipped with a constant current IC, specifically designed for long-distance applications. The built-in IC ensures that regardless of the strip's length or voltage variations, the LED chips receive stable current. This stability guarantees uniform brightness and reliable performance, even over extended distances.

Ultra Run Neon LED Strip Specification

Product Features

1.Color Options: 3000K / 4000K / 6000K available

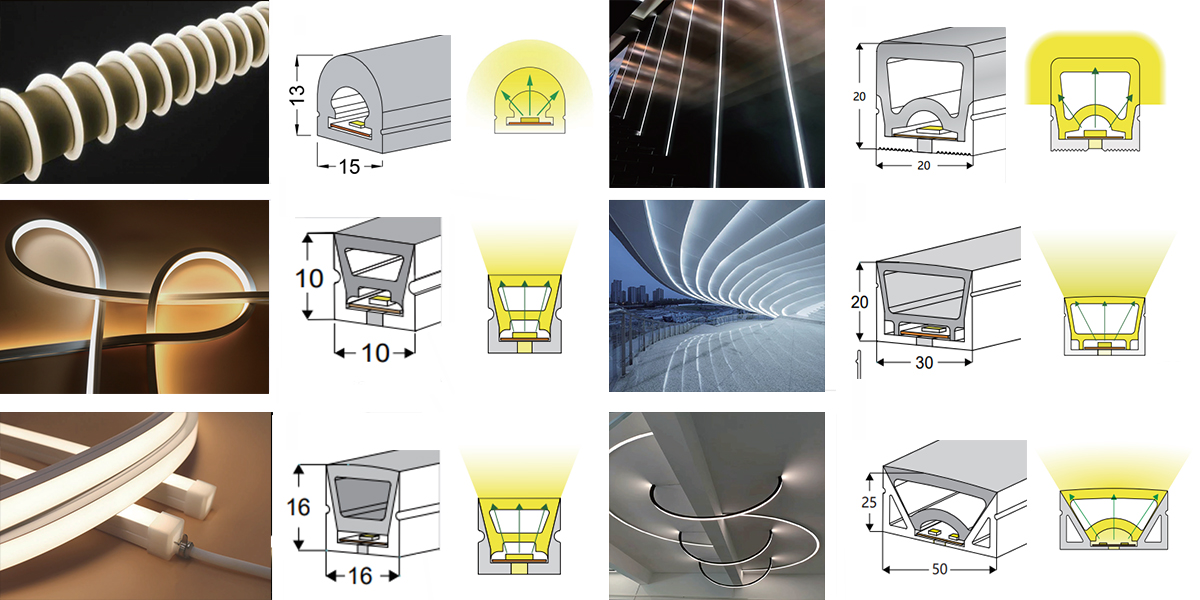

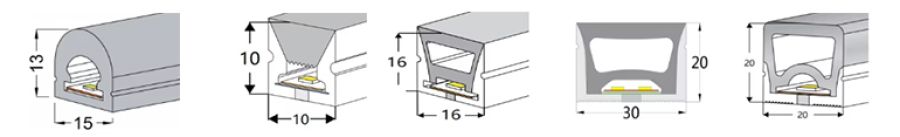

2.Product Dimensions & PCB Width:

- 04*10(mm):5/6mm

- 06*12(mm):8mm

- 06*13(mm):8mm

- 08*17(mm) :8mm

- 12*25(mm):10/12mm

- 16*16(mm):10mm

- 20*20(mm):10/12mm

3.Waterproof Rating: IP67 / IP68 Available

4.Flexible Installation: Easily bendable and moldable to fit various shapes and designs.

5.Customization: Tailor the number of LEDs, PCB width, colors, CRI, and waterproof level according to project needs.

Feel free to contact us for customized solutions that suit your requirements!

Product Specification

| Part No: | Input Voltage | Size | Color | PCB Width | Cover Material | Min Cut | Max Power | IP Grade | Operating Temperature: |

| LW-0410-24V | 24V | 4*10mm | White | 5/6mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T0612-24V | 24V | 06*12mm | White | 8mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T0613-24V | 24V | 06*13mm | White | 8mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T0817-24V | 24V | 8*17mm | White | 8mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T1018-24V | 24V | 10*18mm | White | 10mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T1225-24V | 24V | 12*25mm | White | 10/12mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T1616A-24V | 24V | 16*16mm | White | 10mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| LW-T2020A-24V | 24V | 20*20mm | White | 10/12mm | Silicon | Cut Free | 12-14W/M | IP67 | .-25℃ to +60℃ |

| Various sizes are available for customization, welcome to contact us . | |||||||||

Products Details

01. Multiple Size Options

Our Ultra Run Neon LED Strip are available in a variety of sizes and colors, offering versatile designs to suit different projects. Available sizes include:

04*10mm/06*12mm/06*13mm/08*17mm/12*25mm/16*16mm/20*20mm/20*14mm

02. Extrusion and Sleeve Process Options

- Sleeve Process: The neon sleeve is pre-manufactured, and the LED strip is inserted into the sleeve afterward.

- Extrusion Process: The LED strip is fully encapsulated during production using an integrated molding machine for a seamless finish.

Watch the video: Extrusion Process Demonstration

03. Silicone Material

- Silicone: Known for its superior resistance to yellowing, aging, and extreme temperatures, making it ideal for outdoor applications. Although slightly higher in cost, it ensures longevity and durability.

- PVC: A more affordable alternative but less resistant to yellowing and aging over time.

These material choices allow flexibility in balancing budget, durability, and performance requirements for various applications.

![]()

04.Waterproof Connectors

Male and female connectors are designed for easy manual connection while ensuring excellent waterproof performance.

These connectors make the entire strip water-resistant and secure for outdoor use.

05. IP67 Waterproof Rating for Outdoor Use

The flexible neon LED strips are rated IP67, suitable for outdoor installations. During outdoor installation,

attention must be paid to waterproofing, aging, and thermal expansion/contraction due to adverse weather conditions.

- Primary Waterproofing: At our manufacturing facility, we implement waterproof treatments tailored to the molding process. For single-shot molding, waterproof connectors and stainless steel rings are added to seal open ends, enhancing durability.

- Secondary Waterproofing: If secondary molding is requested, additional waterproofing measures are taken during packing as per the custom order. Special care is given to interface positions to ensure robust waterproofing.

For more detailed waterproofing instructions and options, feel free to reach out to our technical team.

06. Customizable Lengths

We offer tailored length options based on customer requirements. The shortest possible length is 1cm, while the longest continuous length can reach 20–30 meters, powered from both ends to prevent voltage drops. This customization ensures optimal performance for various projects and applications.

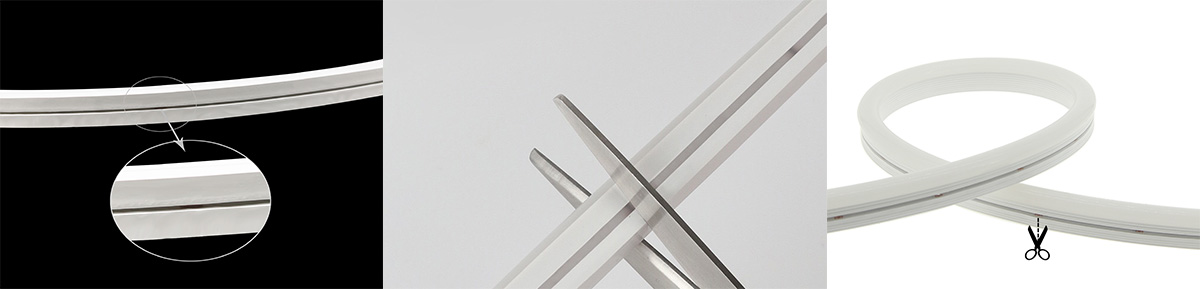

07. Cuttable and Flexible Design

The neon LED strip features cutting lines on the back, allowing precise and convenient cutting to fit your specific needs. Its flexibility makes it ideal for installation on various shapes and curves, enabling seamless integration into diverse spaces.

Watch our demo video: Installation and Customization Guide

For further customization inquiries, feel free to contact us!

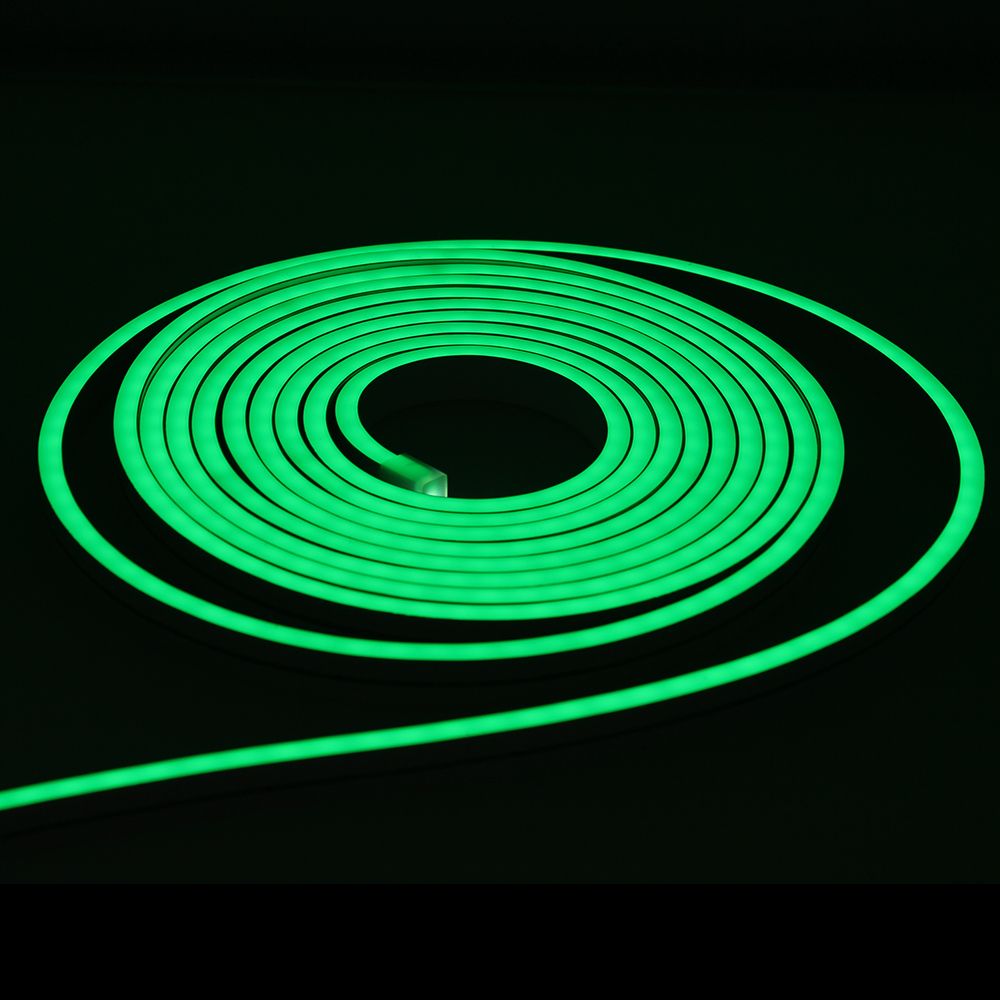

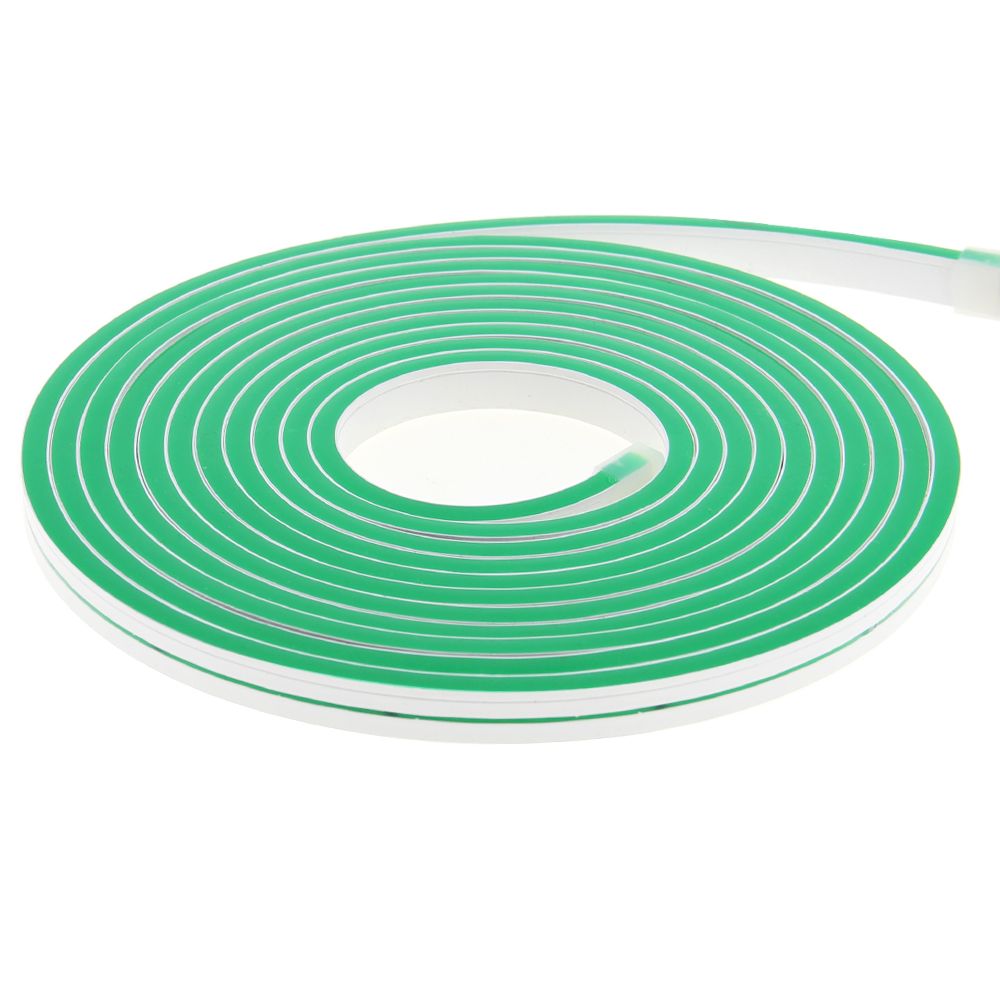

Images of Ultra Run Neon LED Strip

Here is some of product show in real situation:

Videos of Ultra Run Neon LED Strip

Custom LED Strip Supplier & Manufacturer

At LEDWorker, we offer specialized customization services for our LED Neon Flex products, allowing each client to tailor the product to meet unique requirements. Our customization options include:

LED Density: We can adjust the LED count per meter to achieve a specific lighting effect, improving the linear appearance with higher densities.

PCB Customization: Depending on the installation environment, we can adjust PCB widths and configurations to enhance brightness and heat dissipation. For specific designs, we also offer options like dual- or triple-row configurations and flexible "S-shape" PCBs.

Color Temperature: Our standard color temperatures include 3000K, 4000K, 6000K, 8000K, and 10,000K. For projects requiring specific color outputs, we can further customize based on color coordinates (x, y values) to match any desired color spectrum.

Neon Flex Sizes: LEDWorker provides a range of standard sizes, but for projects needing unique dimensions, we offer OEM or ODM options, requiring mold customization to meet these specifications.

Packaging Customization: We offer tailored packaging solutions, including labels, bag designs, boxes, and display options, ensuring a complete and cohesive presentation.

With experience providing OEM and ODM services to major brands and meeting ISO9001, CE, RoHS, and UL certifications, we’re committed to delivering high-quality, tailored solutions for each project. If you’re interested, our sales team is available 24/7 to discuss your specific needs and provide a seamless buying experience.

Dimensions

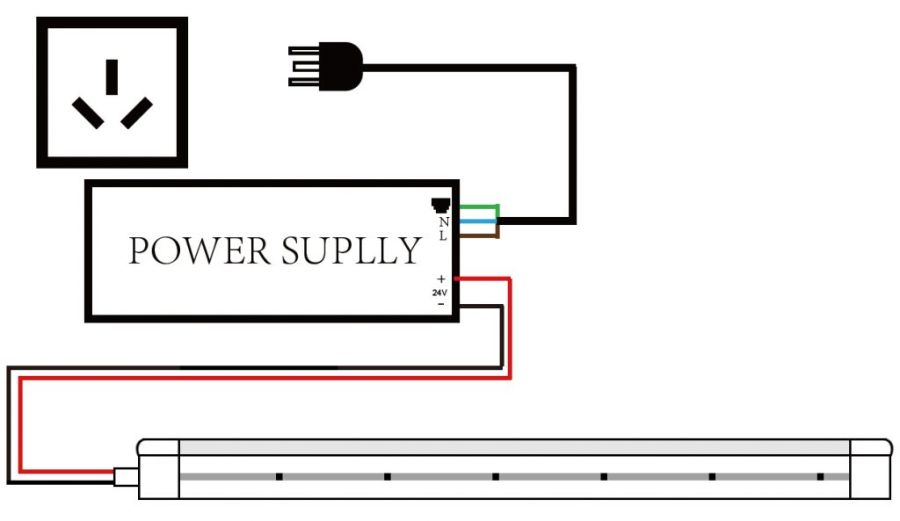

Connect Drawing

Ultra Run Neon LED Strip Application

Ultra Run Neon LED Strip finds wide applications in LED lighting across various domains, offering unmatched flexibility and uniform illumination. Its key applications include:

Ultra Run Neon LED Strip is extensively used in urban beautification projects, enhancing nighttime aesthetics of buildings or scenic areas. Ideal for large-scale, long-distance lighting needs.

Perfect for large structures such as bridges and docks, these strips provide consistent and uniform lighting, enhancing both the visual appeal and safety of these spaces, particularly in nighttime or low-light conditions.

Widely applied to building exteriors and facades, its flexible length and uniform lighting effect create stunning visual highlights, adding beauty and impact to architectural designs.

Ideal for malls, shops, and restaurants, Ultra Run Neon LED Strip attracts customer attention while providing consistent lighting. It enhances commercial ambiance, promotes brand identity, and adds to the overall appeal of the space.

From nightclubs to bars and performance venues, these neon strips create dynamic environments. Their varied light effects and color changes enhance the entertainment experience and add a modern, vibrant touch.

Ultra Run Neon LED Strip is excellent for wall-washing applications, illuminating building surfaces with even light, highlighting textures and layers. It is especially suitable for art installations, cultural buildings, and decorative walls.

Ultra Run Neon LED Strip offers endless possibilities for both aesthetic and functional lighting solutions, making it an essential choice for diverse projects.

Installation

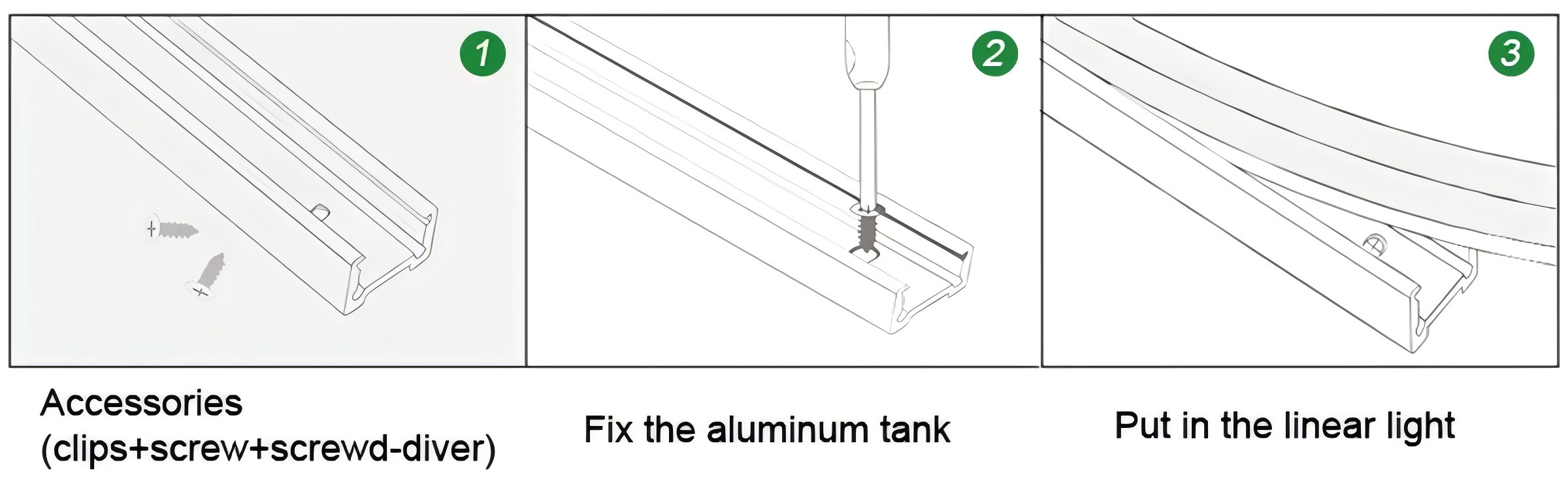

Aluminum tank

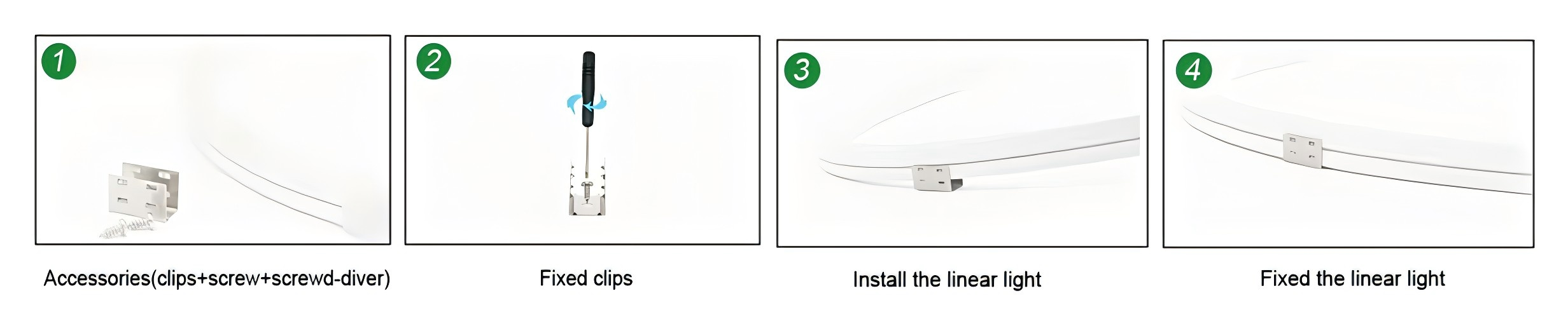

Buckle installation

Accessories

To ensure efficient and seamless installation, Top View Neon LED Strips come with various practical accessories:

- End Caps:Available in different configurations: straight, left-out, and right-out, suitable for different installation requirements.

- Waterproof Connectors:Male and female connectors designed for easy, secure hand connection. They enhance the waterproof performance, making the entire strip weather-resistant.

- Aluminum Profiles:Provide structural support and assist in heat dissipation for better durability. They also help in creating clean, sleek installations.

- Screws and Clips:Essential for securely fastening the LED strips and profiles in place, ensuring a neat and sturdy setup.

These accessories make the Top View Neon LED Strip adaptable for a variety of applications while maintaining durability and aesthetics.

End Caps Connectors Aluminum profiles Screw & Clips

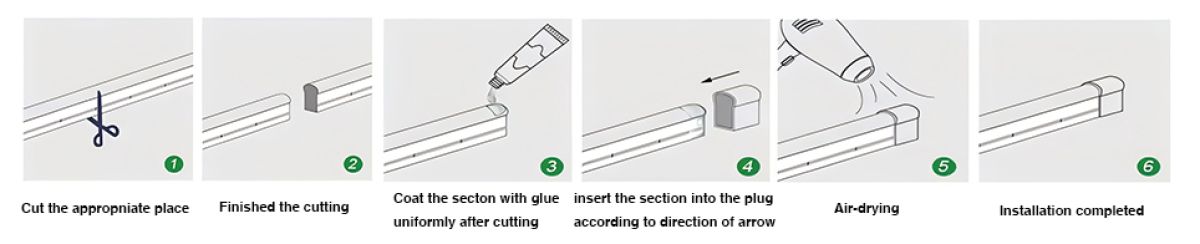

How to cut and connect it

- It is feasible to cut along the black point on the side of led strp.Do notcutoptionally to avoid damage to led strip.Cut the appropniate place

- Finished the cutting

- Coat the secton with glue uniformly after cutting

- insert the section into the plug according to direction of arrow

- Dry the plug with hot wind or natural wind until nake sure the installation is firm

- The effct of finished plug installaion

How we guarantee the quality

As a professional LED manufacturer, we ensure that all our LED strips undergo rigorous testing to guarantee their quality and durability. Below are the specific tests, conditions, cycles, criteria, and equipment used to maintain high product standards:

|

Product Reliability Project |

||||

|

Test Item |

Test Conditions |

Duration/Cycle |

Judgment condition |

Use equipment |

|

Thermal Shock |

–40℃ 30min↑↓5sec100℃ 30min |

200cycles |

No cracked glue, no dead light |

Hot and cold shock box |

|

Humidity Heat Storage |

Ta=85℃、RH=85% Rated voltage |

1000hr |

Luminous decay≤10%,no cracked glue, no dead light |

High temperature and humidity box |

|

Life Test |

Ta=25℃ Rated voltage |

1000hr |

Luminous decay≤3%,no cracked glue, no dead light |

Room temperature aging seat |

|

High Humidity Heat Life Test |

60℃ RH=90% Rated voltage |

1000hr |

Luminous decay≤10%,no cracked glue, no dead light |

High temperature and high humidity aging box |

|

Twist Test |

360°/cycle Fixed and twisted at both ends |

300 |

No dead light, no cracked glue |

Distortion test machine |

Packing

FAQs

Here is the top frequent asked questions. If you are still not very clear, feel free to content our consultant for more details.

We offer FREE SAMPLES for your business.

When comparing the lifespan of neon and LED lights, LEDs generally have a much longer lifespan:

LED lights: Typically last between 25,000 to 50,000 hours or even more.

Neon lights: Usually last around 10,000 to 15,000 hours.

Constant voltage LED strips: The maximum run length is usually 5 meters.

Constant current LED strips: The maximum run length can go up to 50 meters.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.