COB LED Strip

The COB (Chip on Board) LED Strip is a versatile and efficient lighting option with the following features:

- Voltage Options: Available in 5V, 12V, and 24V.

- Chip on PCB: LED chips are directly mounted onto the PCB for a dot-free, smooth light output.

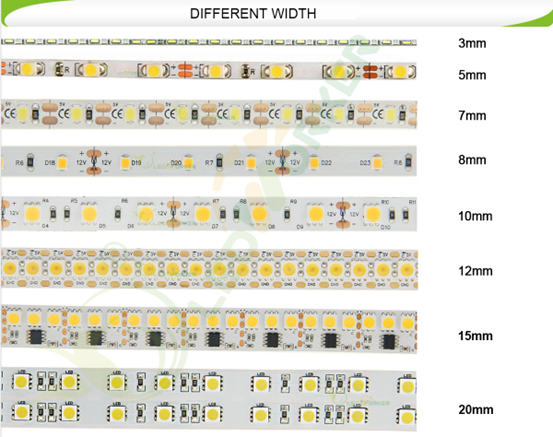

- PCB Width: Available in various widths such as 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, and 12mm.

- LED Density: Options include 320, 360, 400, 450, 480, 576, 608, and 840 LEDs per meter.

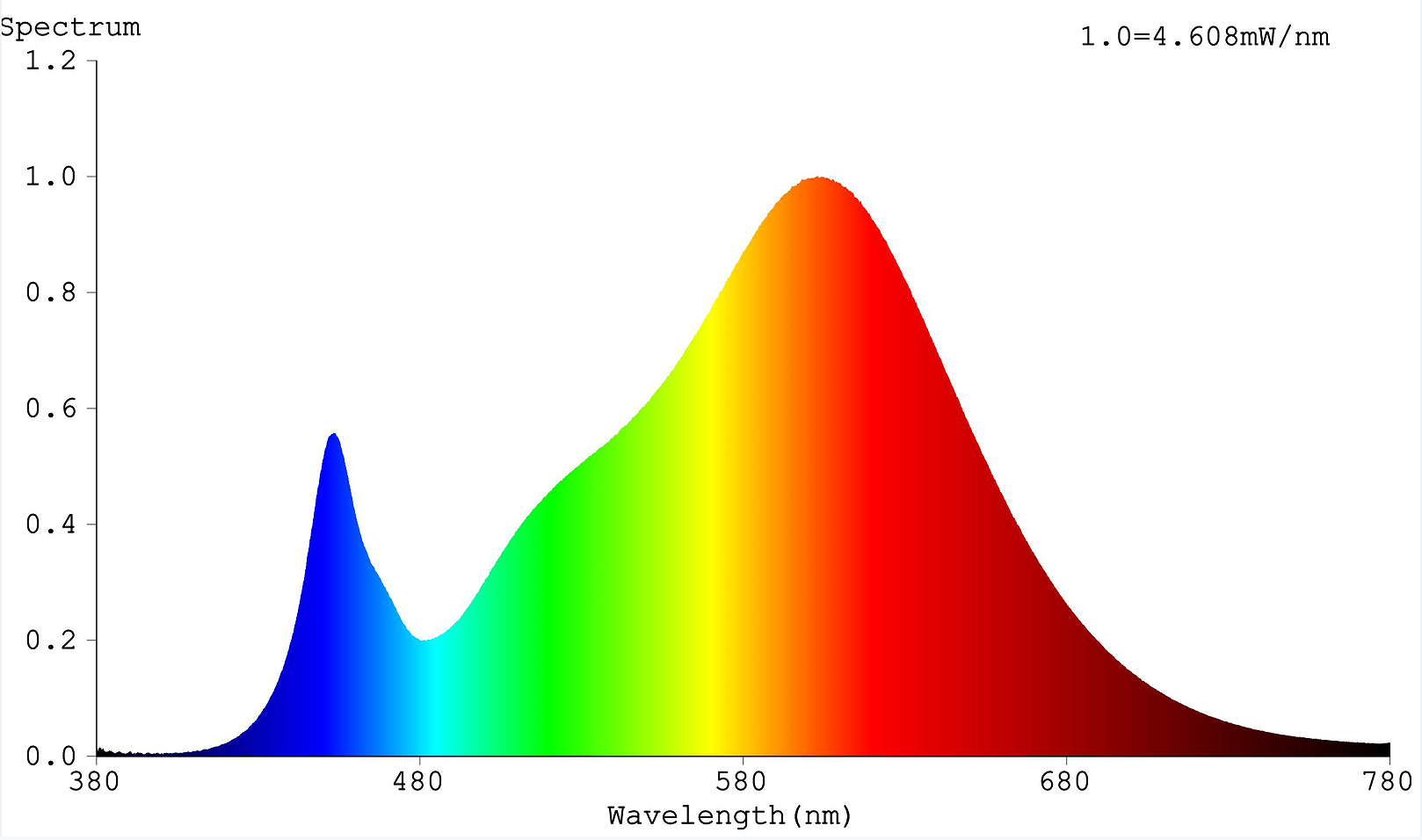

- High CRI: CRI >90, ensuring high color accuracy and uniform lighting.

- Color Options: Offers a range from warm to cool whites (2700K to 6000K) and colors like red, green, blue, yellow, dual-color, RGB, RGBW, RGBCW, and dynamic options like color-changing white and RGB COB.

- Longevity: Designed for a long life of up to 50,000 hours with minimal brightness degradation.

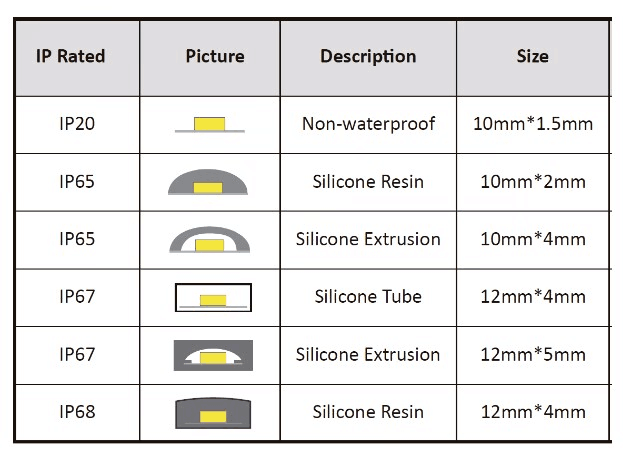

- Waterproofing: IP ratings available from IP20 to IP68, catering to both indoor and outdoor applications.

- Easy Installation: Flexible, cuttable, and backed with 3M adhesive for straightforward installation.

COB LED STRIP Supplier & Manufacturer

Shenzhen LEDWorker Lighting Co., Ltd is Located in Shenzhen City , established in 2012 . It has five fully automatic production lines. Monthly capacity of single product is 1 million meters to Handle Bulk Orders of Standard Led Strips and Various Forms of OEM & ODM LED Strip Lights.

We understand the importance how to provide the suitable products to help you earn the market. You need more than a supplier, We hope to establish long term business relationship and get the win win situation.

With sucessful experience of the support our customer and let them to be the No.1 in the market. We have confident to offer a very suitable products that will satisfy your requirements. If you have any request pls contact with our sales team, they will 24 hours 7 days working for you and give you one stop purchase experience.

Manufacturing process of COB LED Strip

- First, apply the solder paste to the PCB pad through the automatic solder paste brushing machine. The uniformity and thickness of the solder paste determine the quality and flatness of the soldered chip, as well as the quality of the soldered chip.

- Load the solder paste-coated PCB board on the carrier, input and set the die bonding program of the chip through computer programming, debug the direction and height of the die bonding, and confirm the electrode direction of the chip.

- Do a small-batch bond test first, and inspect the appearance quality of the PCB with a good bond to determine the direction of the bond, whether there is solder paste connected, and whether the location of the bond is correct, and the inspected product flows into the next process.

- After testing the LED chips on the PCB board, perform the powder mixing process of silica gel and phosphor powder. According to the photoelectric parameters such as color temperature and brightness specified by the customer, configure different proportions, and degas the glue with vacuum.

- Fix the PCB board on the dispenser carrier for the dispensing process. The dispensing process is the most critical process for the success of the strip light. After dispensing, put the PCB board in the oven for baking, and the glue from different manufacturers is baked. If the baking conditions are inconsistent, you must refer to the manufacturer’s requirements for verification before setting the appropriate baking temperature.

- Test the color temperature of the light strip after the glue is dispensed, and see if the test data meets the customer’s requirements.

- After welding a 0.5-meter PCB board, connect it to requirements ranging from 5-10 meters, and then cut the entire circuit board into strips

- Continuously energize for 6-8 hours for aging.

- After the end of aging, perform function test and endurance test.

- There is no problem in the function test, apply glue, and then wrap the light strip with a reel.

- The whole plate test, whether there is any bad condition through the squeeze and twist test

- Pack the entire plate of COB LED strips in bags and prepare for shipment

What is COB LED STRIP

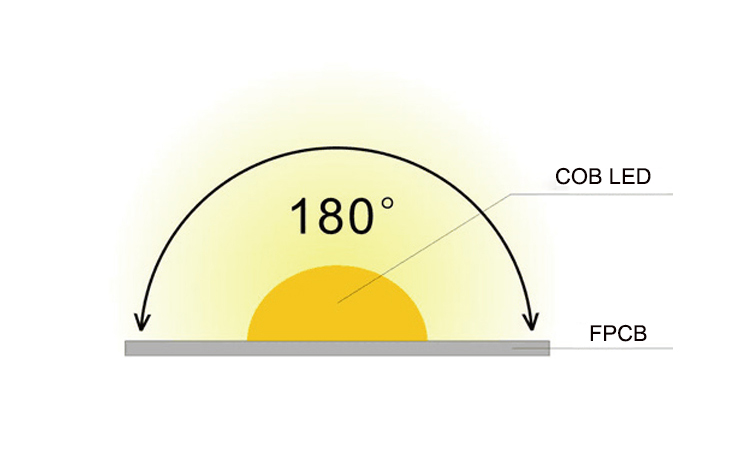

A COB LED strip (Chip On Board) is a type of LED strip where LED chips are directly bonded onto a printed circuit board (PCB). Unlike traditional LED strips, which use individual LED packages, COB LED strips involve placing multiple tiny LED chips directly on the PCB surface. A layer of phosphor-encapsulated glue is then applied over the chips to diffuse light and provide a uniform glow. This process results in dot-free illumination, with a wide beam angle of 180°, offering smooth, consistent lighting with no visible individual LED dots.

Key Features of COB LED Strips:

- Dotless Lighting: The chips are densely packed, resulting in a smooth, continuous light output with no visible hot spots or dots.

- Wide Beam Angle: The strips emit light at a 180-degree angle, making them perfect for applications requiring wide-area lighting.

- Flexible and Customizable: COB LED strips are available in various PCB widths (ranging from 3mm to 12mm), voltages (5V, 12V, and 24V), and LED densities (320 to 840 LEDs per meter).

- High Color Rendering Index (CRI): With a CRI of 90+, COB strips provide excellent color accuracy, making them ideal for applications requiring high color fidelity.

- Color and Temperature Options: Available in multiple colors, including warm and cool white (2700K-6000K), RGB, and special colors like red, green, blue, and yellow.

- Durability: COB LED strips have a lifespan of up to 50,000 hours and can be made waterproof (IP20 to IP68), suitable for indoor and outdoor use.

Advantages of COB LED Strips:

-

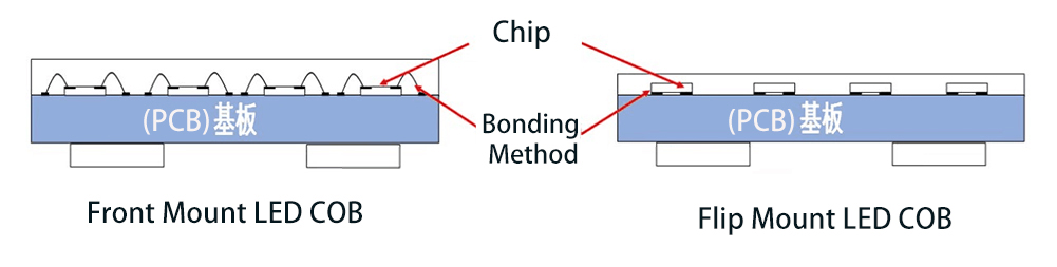

Cost Efficiency: COB LED strips use flip-chip technology, which offers a cost advantage when using the same number of LED chips compared to other LED strips like SMD.

-

Better Heat Dissipation: The heat dissipation path is shorter, resulting in lower thermal resistance, which reduces light decay and extends the strip's lifespan.

-

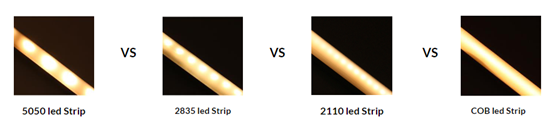

No Visible Light Spots: COB LED strips feature continuous phosphor encapsulation, which eliminates visible light spots, providing smooth and soft illumination, ideal for creating a DOT-FREE lighting experience. This is particularly effective when installed in aluminum channels, where other types like 2835, 5050, or 2110 would show visible light dots.

- Lighting Angle: COB strips offer a wide beam angle of 180 degrees, ensuring broader light coverage.

- No Silver Plating: Eliminates the risk of vulcanization.

Disadvantages of COB LED Strips:

- Color Consistency: Achieving uniform color consistency is harder compared to SMD LED strips. In SMD production, LED chips undergo a binning process for consistent color matching, while COB involves directly applying phosphor over the chip on the PCB, making it harder to control uniformity.

- Lower Power: Due to the dense arrangement of chips, COB LED strips have limited heat dissipation, capping their power output at around 14W per meter, while SMD strips can go up to 18W or higher.

- Lower Luminous Efficiency: COB LED strips generally have lower luminous efficiency, with a maximum of around 100LM/W. In contrast, high-power SMD LED strips can reach up to 160-170LM/W. Therefore, for brightness above 120LM, high-brightness SMD LED strips may still be required.

- Durability Issues: COB LED strips are more prone to damage from repeated bending or pulling, especially during the manufacturing of waterproof versions. The chips are directly embedded onto the PCB, and the small size makes them more vulnerable to detachment, resulting in dead LEDs.

Why Choose COB LED Strip?

Choosing COB (Chip On Board) LED strips offers several distinct advantages compared to traditional SMD (Surface Mounted Device) LED strips, making them an increasingly popular choice for various lighting applications. Here are the key reasons to choose COB LED strips:

COB LED strips provide smooth, continuous light with no visible light spots, making them ideal for applications where a clean, uninterrupted light source is desired. This is achieved due to the higher chip density (up to 480 or more chips per meter), which results in a more consistent light output with no gaps or dark areas.

COB LED strips are more cost-effective because the chips are directly mounted on the PCB without the need for packaging each chip into an individual SMD unit. This direct mounting reduces the overall cost, especially when considering that COB strips can house significantly more LED chips in the same space compared to SMD LED strips.

Since the LED chips are directly attached to the PCB, heat is efficiently dissipated. This prevents overheating, reduces light decay (lower light degradation over time), and extends the overall lifespan of the strip.

COB LED strips offer versatile design options with various PCB widths (ranging from 3mm to 12mm) and chip densities (e.g., 320/360/480/608/840 LEDs per meter).

They also come in single-color, dual-color, RGB, RGBW, RGBCW, and even dynamic color-changing options like addressable RGB or dynamic white (CCT tunable).

The linear light output from COB LED strips is soft and even, providing a sleek and dot-free illumination. This makes them ideal for creating ambiance, indirect lighting, or enhancing the depth and layering of spaces in modern interior designs.

COB LED strips offer high CRI values (up to 95+), which means they render colors more accurately and vividly, making them suitable for areas where color accuracy is important, such as in retail displays or photography setups.

COB LED strips are easy to install due to the 3M adhesive backing, which allows for simple application on various surfaces. However, it's important to be cautious during installation as the silicone encapsulation is soft and can be damaged if it comes into contact with sharp objects.

Installation Tips:

- Keep the strip clean during installation to avoid dust accumulation on the silicone encapsulation.

- Avoid repeatedly removing and reapplying the strip to maintain the adhesive's effectiveness.

COB LED Strip Application

COB LED strips are becoming increasingly popular in various lighting applications due to their uniform light distribution and dot-free appearance. Here are some of the key areas where COB LED strips are widely applied:

COB LED strips provide smooth, even lighting, making them perfect for creating ambiance and adding depth to spaces. They are commonly used in:

- TV background walls: For soft backlighting that reduces eye strain while watching TV.

- Ceilings and cove lighting: To highlight architectural features and create a warm, inviting atmosphere.

- Cabinet lighting: Ensuring consistent illumination across shelves without visible light spots.

- Staircase lighting: Enhancing safety while adding an aesthetic touch.

- Vanity mirrors: Ideal for vanity mirrors due to their high CRI and spot-free illumination, making them a popular choice among manufacturers of vanity lighting.

n commercial environments like shopping malls and hotels, COB LED strips are utilized to enhance the visual appeal and create distinct lighting layers:

- Display lighting: Provides uniform, high-quality lighting for showcases and display cases, ensuring products are well-lit and visually appealing.

- Architectural outlines: They are often used to outline building facades and highlight specific architectural elements.

- Landscape lighting: COB LED strips in warm colors are frequently used to enhance landscapes, such as trees, lakes, and building contours, adding a warm, inviting glow.

COB LED strips are popular in entertainment venues like KTVs, nightclubs, and bars for their ability to create dynamic visual effects and high brightness levels. These strips are used to:

- Enhance ambiance with colorful lighting that syncs with music.

- Create unique lighting effects that elevate the overall experience for customers.

Wholesale COB LED Strip By Series

Your company is clearly equipped with advanced technology and modern manufacturing capabilities, especially when it comes to producing and processing various types of LED strips, including standard LED strips, as well as custom OEM and ODM orders. The automated production lines ensure high efficiency, precision, and reduced labor costs by allowing one worker to operate multiple machines. This level of automation minimizes human intervention, reducing the chance of errors while maintaining product quality and lowering production costs.

The variety of COB LED strips your company offers, including single-color strips in 2700K, 3000K, 4000K, and 6000K color temperatures, as well as other vibrant colors like red, green, blue, orange, amber, and pink, ensures versatility for different lighting needs. Furthermore, your company provides more specialized products like dual-color COB strips, RGB COB strips, RGBW COB strips, and RGBCW COB strips to cater to a broader range of lighting applications.

All of your COB strips come with 3M adhesive backing, making installation straightforward and secure. The flexibility of the strips, along with options for different types of 3M adhesives based on the installation environment, ensures adaptability across a range of uses, from indoor to outdoor applications.

With short delivery times of 3-5 days for standard orders and 10-15 days for OEM orders, coupled with your ability to provide custom design services and packaging, your company is well-positioned to offer efficient, cost-effective, and tailored lighting solutions.

-

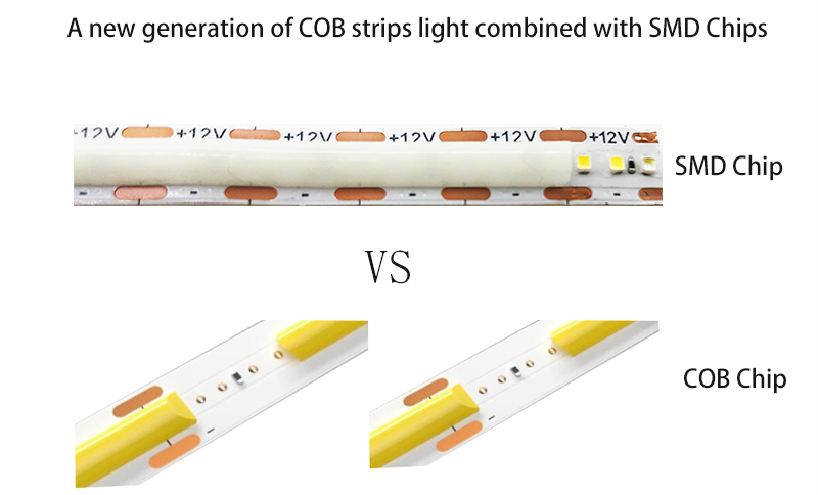

New Generation COB LED Strip

-

Single COB LED Strip

-

Dual Row COB LED Strip

-

Dual Color COB LED Strip

-

RGB COB LED Strip

-

RGBW COB LED Strip

-

RGBCW COB LED Strip

-

Chasing White COB LED Strip

-

Chasing Dual Color COB LED Strip

-

Chasing RGB COB LED Strip

-

High Voltage COB LED Strip

-

48V COB LED Strip

-

Cuttable COB LED Strip (Single LED Cuttable)

Customized Solutions for COB LED Strips

At LEDWorker, we offer professional custom services for our LED strip lights to meet diverse needs, including designing manuals, labels, packaging, and custom logos.

Customization Options:

- LED Quantity per Meter: We adjust LED density to enhance linear light effects. Higher LED density creates a more seamless and even light output.

- Custom PCB Design: Based on the environment, we offer various PCB designs, including narrower widths for tight spaces, wider boards for better heat dissipation, double or triple-row configurations, and flexible S-shaped designs.

- Waterproofing Levels: We customize waterproofing to fit different environments. Options range from IP20 (non-waterproof) to IP68 (full waterproof), depending on installation needs.

- Custom Color Temperature: Standard temperatures are 3000K, 4000K, 6000K, 8000K, and 10000K, but we can create specific temperatures based on spectral chromaticity coordinates if required.

- Color Bin (MacAdam Step): We typically provide a three-step MacAdam binning standard but can offer single-step binning if needed for enhanced color consistency.

- CRI Customization: For clients with specific color rendering index (CRI) needs, we can offer CRI 90 or CRI 95 values, even for specialized environments like photography studios.

- Custom Packaging: We can create tailored packaging, including labels, bags, boxes, and display stands, ideal for retail and bulk clients.

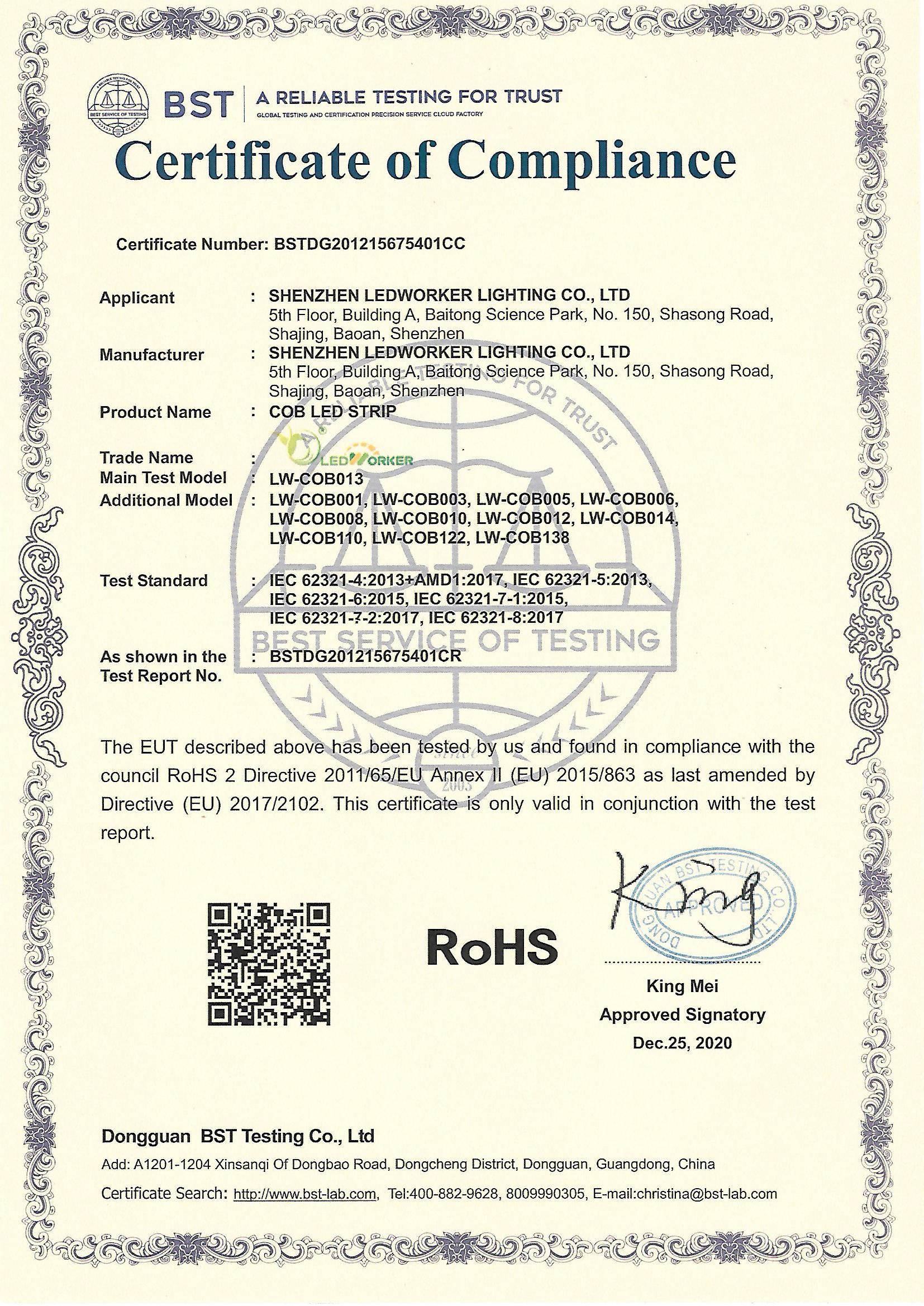

Industry Expertise: We bring years of customization experience, having served notable clients such as Ford and Best Buy with OEM and ODM services. Our products adhere to ISO9001, CE, RoHS, and UL standards, ensuring quality and reliability.

For any inquiries, our sales team is available 24/7 to provide comprehensive support.

With our extensive experience in customizing LED strips, we have provided OEM and ODM services to well-known brands like Ford and Best Buy. All our products comply with ISO9001, CE, RoHS, and UL certifications. We are confident in our ability to deliver products that meet your specific needs. If you have any requests, please contact our sales team—they are available 24/7 to offer you a comprehensive purchasing experience.

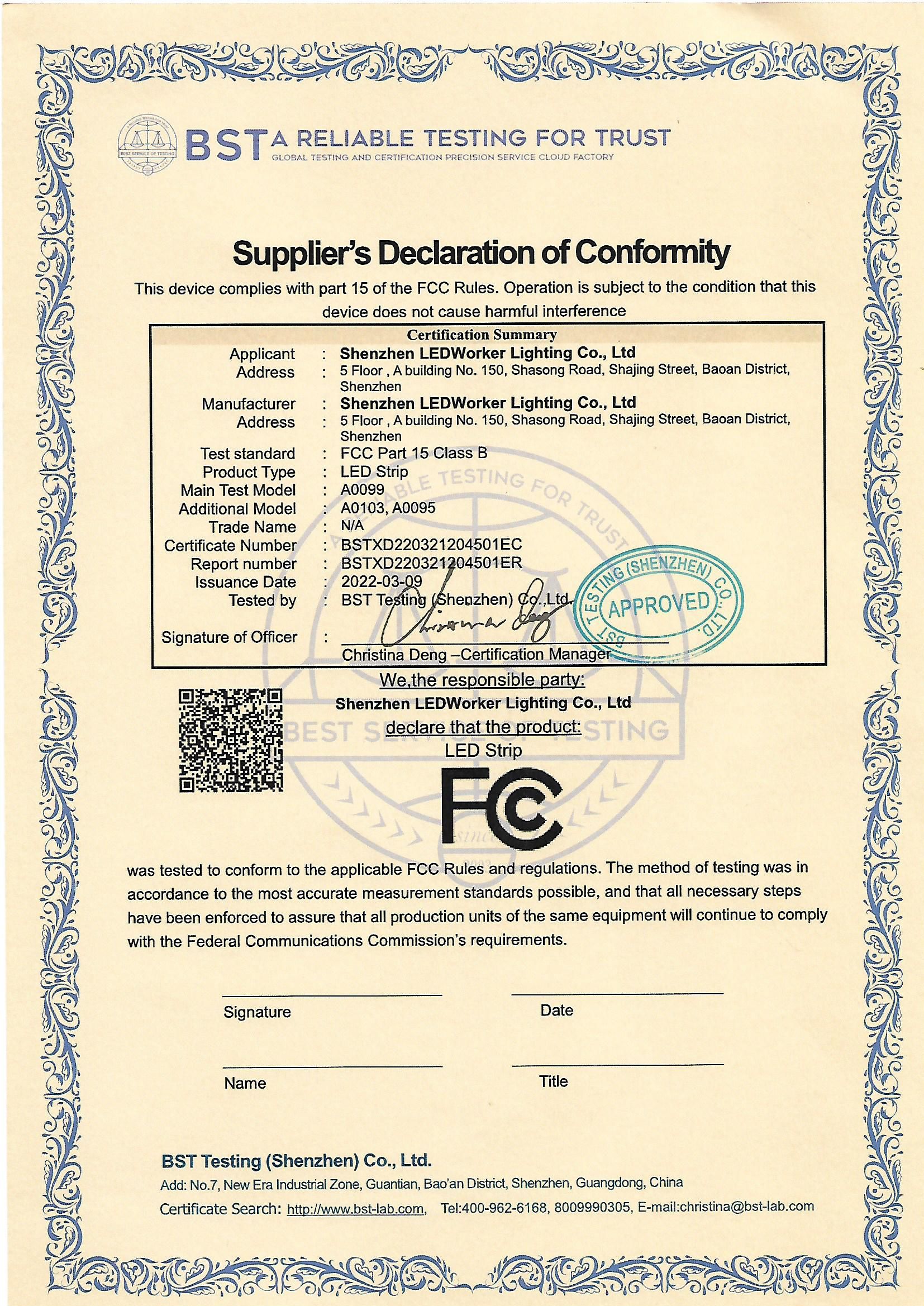

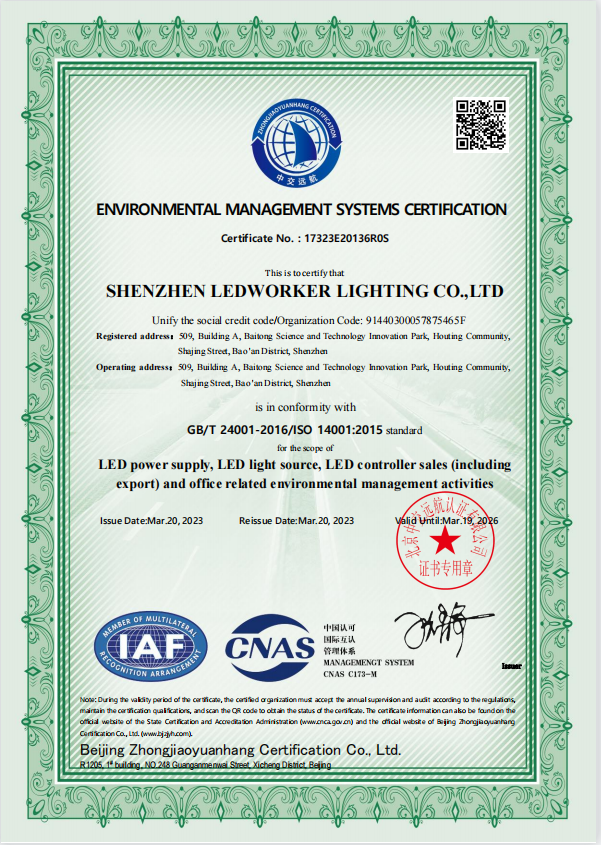

Certifications at LedWoker

At LEDWORKE, we are committed to our core values of customer-centricity and quality-first. Our goal is to build a modern, large-scale, and international company, and to that end, we have obtained various certifications to guarantee the quality and reliability of our products.

Certifications include:

ISO9001: Quality Management System certification.

ISO14001: Environmental Management certification.

TUV: Certification for safety and quality.

Our single-color LED strips have passed the following certifications:

CE: Ensures that our products comply with EU safety, health, and environmental requirements.

ROHS: Certifies that our products are free from hazardous substances.

ETL: Recognizes product compliance to North American safety standards.

REACH: Guarantees that our products adhere to regulations concerning the safe use of chemicals in the EU.

UL: Ensures that our products meet rigorous safety standards, especially for the U.S. market.

Additionally, we can provide specific testing reports per customer requests, including:

Salt Spray Test Reports: For evaluating corrosion resistance.

ERP Test Reports: Related to energy consumption and performance.

LM80 Test Reports: For long-term lumen maintenance.

EN 62471: Compliance with blue light hazard standards.

Testing

As a professional LED manufacturer, LedDesignsPro ensures that all of our LED strips undergo rigorous testing to guarantee top-notch quality and reliability. Our products are subjected to repeated cycles of thermal shock, high temperature and humidity storage, normal temperature aging, high humidity heat aging, and twist testing. Additionally, we utilize the Spektron coating integrating sphere to accurately measure the luminous flux (LM value) of our LED strips, maintaining strict quality control throughout the production process.

Below are the specific testing conditions, cycles, judgment criteria, and the equipment used:

| Test Item | Test Conditions | Duration/Cycle | Judgment Condition | Use Equipment |

|---|---|---|---|---|

| Thermal Shock | –40℃ 30min ↑↓ 5sec 100℃ 30min | 200 cycles | No cracked glue, no dead light | Hot and cold shock box |

| Humidity Heat Storage | Ta=85℃, RH=85%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and humidity box |

| Life Test | Ta=25℃, Rated voltage | 1000 hours | Luminous decay ≤3%, no cracked glue, no dead light | Room temperature aging seat |

| High Humidity Heat Life Test | 60℃, RH=90%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and high humidity aging box |

| Twist Test | 0.5M fixed at both ends, twisted 360°/cycle | 300 cycles | No dead light, no cracked glue | Distortion test machine |

Why Wholesale LED Strip In Bulk From Us

Choosing to wholesale LED strips from LedWoker comes with numerous benefits designed to meet the needs of your business:

Quality and Safety

At LedWoker, we prioritize quality and safety. All of our LED strips are manufactured using the finest materials and undergo rigorous testing to ensure they meet the highest standards. Every product is certified with CE and RoHS certifications, guaranteeing that our LED strips are both safe and reliable for a variety of applications.

Competitive Pricing

By producing our own LED chips and controlling every step of the manufacturing process, we are able to offer our products at highly competitive prices. This allows you to maximize your profit margins without compromising on quality.

Customizable Solutions

We understand that different projects have unique requirements. That’s why we offer comprehensive customization options, including LED density, PCB width, waterproofing levels, and color temperature. Whatever your project demands, we can deliver LED strips tailored to your exact specifications.

Production Capabilities

With our advanced manufacturing facilities and high production capacity, LedDesignsPro is equipped to handle bulk orders with ease. Whether you need thousands of meters for a large commercial project or a specific design for a niche market, we have the capacity to meet your demands efficiently and on time.

Fully Support

Our commitment to excellent customer service doesn’t end with the sale. We offer 24/7 support to ensure that your wholesale experience is seamless from start to finish. Our team is always ready to assist you with any inquiries, provide technical support, or help with logistics to ensure timely delivery.

Proven Track Record

We have built long-term relationships with clients worldwide, including well-known brands and large-scale distributors. Our consistent product quality, reliable service, and flexible solutions have earned us a reputation as a trusted supplier in the LED lighting industry.

FAQs

Here are top asked questions, feel free to contact us for more details.

We refer to this new technology as roll-to-roll COB LED strips. "Roll-to-roll" describes a manufacturing process where a roll of PCB (typically 100 meters or 200 meters per roll) goes through fully automated equipment such as soldering machines, chip mounters, dispensing machines, and tunnel furnaces to be formed automatically. Traditional LED strips, including common COB LED strips, use 0.5-meter PCB boards. When customers need a 5-meter strip, workers connect 10 pieces of 0.5-meter LED strips together. However, with roll-to-roll technology, the strip is produced in rolls of 100 meters. If a customer needs a 5-meter product, it only requires a single cut, making it more efficient and saving labor costs. The fully automated equipment can work continuously, increasing production, speed, and reducing costs. Roll-to-roll LED strips are the latest product from LEDWorker Lighting Company, with a monthly output of over 1 million meters.

The main waterproof forms of LEDWorker Lighting are: IP65, drip silicone glue on the PCB for waterproof, IP67, casing silicone tube for waterproof, IP67, Extrusion waterproof. Let’s talk about drip waterproof (IP65), because COB LED STRIP surface has a layer of silicone, and then add a layer of silicone to waterproof, it will lead to the two layers can not be well integrated, so you can not do drip waterproof. Casing (IP67) is no problem. Extrusion can be done, but the defect rate is high, in the over extrusion machine because the temperature is too high need to do some special treatment of COB LED STRIP, after extrusion into finished products will no longer have problems。

COB LED STRIP can be cut. Different COB led strip have different minimum cutting distances. For the convenience of installation, we generally do: 12V 25mm, 24V 50mm scissors. Once you find the scissors, you can cut straight. If you need to connect them again, you can use the middle connector. The advantage of this connector is that it is transparent and will not block light, and it can perfectly connect two led strip. Connectors generally have three different widths of 6mm, 8mm, and 10mm, corresponding to three different widths of PCB boards. The 90 degree cable connector can be used in the middle, helping to use it together in places that don’t need lights in the middle. The End connector can be connected to the end of the COB led strip to connect the power supply.

COB led strip has the same lifespan as SMD strips.

Conventional color temperatures are: 2700/3000/4000/6000K. In order to ensure his consistency, we put the error value in the smallest range. 2700+/- 150K; 3000+/- 200K; 4000+/- 250K; 6000K+/- 350K.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.