Cut Free LED Strip

- Voltage Options: Available in 12V and 24V.

- Chip Type: Uses high-brightness COB (Chip on Board) chips, along with SMD2018.

- PCB Width: Options include 8mm, 10mm, and 12mm.

- LED Count: 320, 400, 480, 512, 528 LEDs per meter.

- CRI (Color Rendering Index): Greater than 90 for high color accuracy and uniform lighting.

- Color Temperatures: Available in 2700K, 3000K, 4000K, and 6500K.

- Power Options: 10W or 14W available.

- Cutting Feature: Can be cut per single LED, allowing for flexible customization.

- Lifespan: Up to 50,000 hours with low energy consumption.

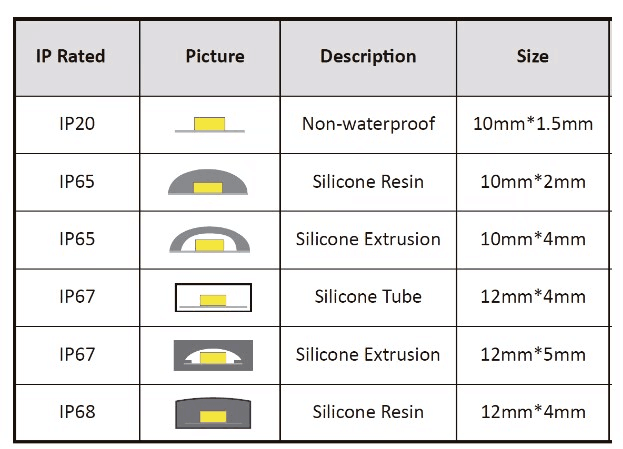

- Waterproof Levels: Available in IP20 (non-waterproof), IP65, IP67, and IP68 (waterproof for outdoor use).

- Installation: Easy to install and bend, with 3M adhesive on the back.

- Customization: PCB width, voltage, power, color temperature, and CRI can be customized according to specific needs.

Cut Free LED STRIP Supplier & Manufacturer

Shenzhen LEDWorker Lighting Co., Ltd is Located in Shenzhen City , established in 2012 . It has five fully automatic production lines. Monthly capacity of single product is 1 million meters to Handle Bulk Orders of Standard Led Strips and Various Forms of OEM & ODM LED Strip Lights.

We understand the importance how to provide the suitable products to help you earn the market. You need more than a supplier, We hope to establish long term business relationship and get the win win situation.

With sucessful experience of the support our customer and let them to be the No.1 in the market. We have confident to offer a very suitable products that will satisfy your requirements. If you have any request pls contact with our sales team, they will 24 hours 7 days working for you and give you one stop purchase experience.

What is Cut Free LED STRIP

Typical LED strips have cutting points at 25mm or 50mm intervals. However, the Cut-Free LED strip allows you to cut it at any desired length without affecting its illumination. Available with both COB and SMD chips, the cutting length can be as short as 1mm. This design is ideal for use with aluminum channels, allowing precise cuts at specific points without causing dark spots or non-functional segments in the strip after cutting.

Why Choose Free Cut LED Strip?

The main reasons to choose the Free Cut COB LED strip are its convenience, flexibility, and simplicity. Unlike standard COB LED strips, the Free Cut COB allows you to cut it to any length needed without creating dark spots, providing more flexibility for custom installations. Standard COB LED strips usually require precise measurements for cutting, but the Free Cut COB strip can be cut anywhere, making it easier to install without worrying about segment lengths or lighting uniformity.

COB technology helps improve heat dissipation efficiency, extending the lifespan of the strip while providing uniform illumination, avoiding shadows and uneven lighting commonly seen with traditional LED strips.

The Cut Free LED strip offers a variety of models to meet different needs. Whether you require specific brightness levels, color tones, or environmental protection, there’s a product that suits your requirements:

- By PCB width: Available in 6mm, 8mm, and 10mm.

- By color: Offers a variety of color options, including 2700K, 3000K, 4000K, 6000K, or customizable colors.

- Environmental protection: Choose from IP20, IP33, IP65, IP67, or IP68 ratings based on the environment, indicating different levels of water and protection.

The Cut Free LED strip is user-friendly in terms of installation, allowing for free cutting to suit various space and design needs, making it particularly suitable for complex installation environments.

LED technology is inherently energy-efficient, consuming far less power than traditional incandescent lights. Although Cut Free LED strips have low power consumption, they deliver high brightness. Additionally, since these strips operate at low voltage, they are a safe option for a variety of lighting applications.

Free Cut LED Strip Application

Free Cut LED strips have become widely used in the LED lighting industry and are gradually becoming mainstream products. Their applications include:

Free Cut LED strips provide uniform and linear lighting effects. Increasingly, modern households use Free Cut LED strips to create ambiance, provide supplementary lighting, and enhance spatial layering. These strips are commonly used for TV background walls, ceiling lighting, under-cabinet lighting, stair lighting, and vanity mirror lights. Their soft, shadow-free lighting and high color rendering index make them ideal for use in vanity mirrors, where only a smooth line of light is visible without individual LED points.

Due to their high color rendering and even lighting, Free Cut LED strips are also widely used in commercial and hotel decor to highlight different spatial levels. They help create a comfortable atmosphere with warm tones. In outdoor parks, green strips can enhance the natural colors of trees, while yellow strips outline lakes. For architectural purposes, warm-colored LED strips are often used to define the contours of large buildings.

KTVs, Bars, and Decorative Use: In entertainment venues like KTVs and bars, the high brightness and vivid colors of Free Cut LED strips are used to create unique atmospheres and visual effects, adding to the overall ambiance of the space.

Wholesale Free Cut LED Strip By Series

We have modern technology and strong manufacturing and R&D capabilities, enabling us to handle bulk orders of standard LED strips and various OEM/ODM designs. Our advanced automated production lines are highly efficient, allowing one worker to manage multiple machines. This significantly boosts production efficiency while reducing labor costs. Due to the high level of automation, minimal human intervention is required during production. Workers only need to intervene when there are errors or alerts, which improves accuracy and reduces costs caused by human error.

We supply various types of Free Cut LED strips, including single-color options with color temperatures of 2700K, 3000K, 4000K, and 6000K. Each strip comes with 3M adhesive backing, making them easy to install and flexible for different environments. The delivery time for standard products is 3-5 days, and for OEM orders, it's 10-15 working days. We also offer free product and packaging design, project support, and cost-effective solutions. Feel free to contact us to discuss your project needs.

-

2018 Free Cut COB LED Strip

-

SMD2018 LED Strip

-

Anywhere COB LED Strip

-

Ultra Thin 5mm Anywhere COB Led Strip

-

Dotless COB Cut Anywhere Linear LED

Custom Free Cut LED Strip

At LEDWorker, we offer professional custom services for our single-color LED strip lights to meet diverse needs, including designing manuals, labels, packaging, and custom logos.

Customization Options:

- LED Quantity per Meter: We adjust LED density to enhance linear light effects. Higher LED density creates a more seamless and even light output.

- Custom PCB Design: Based on the environment, we offer various PCB designs, including narrower widths for tight spaces, wider boards for better heat dissipation, double or triple-row configurations, and flexible S-shaped designs.

- Waterproofing Levels: We customize waterproofing to fit different environments. Options range from IP20 (non-waterproof) to IP68 (full waterproof), depending on installation needs.

- Custom Color Temperature: Standard temperatures are 3000K, 4000K, 6000K, 8000K, and 10000K, but we can create specific temperatures based on spectral chromaticity coordinates if required.

- Color Bin (MacAdam Step): We typically provide a three-step MacAdam binning standard but can offer single-step binning if needed for enhanced color consistency.

- CRI Customization: For clients with specific color rendering index (CRI) needs, we can offer CRI 90 or CRI 95 values, even for specialized environments like photography studios.

- Custom Packaging: We can create tailored packaging, including labels, bags, boxes, and display stands, ideal for retail and bulk clients.

Industry Expertise: We bring years of customization experience, having served notable clients such as Ford and Best Buy with OEM and ODM services. Our products adhere to ISO9001, CE, RoHS, and UL standards, ensuring quality and reliability.

For any inquiries, our sales team is available 24/7 to provide comprehensive support.

With our extensive experience in customizing LED strips, we have provided OEM and ODM services to well-known brands like Ford and Best Buy. All our products comply with ISO9001, CE, RoHS, and UL certifications. We are confident in our ability to deliver products that meet your specific needs. If you have any requests, please contact our sales team—they are available 24/7 to offer you a comprehensive purchasing experience.

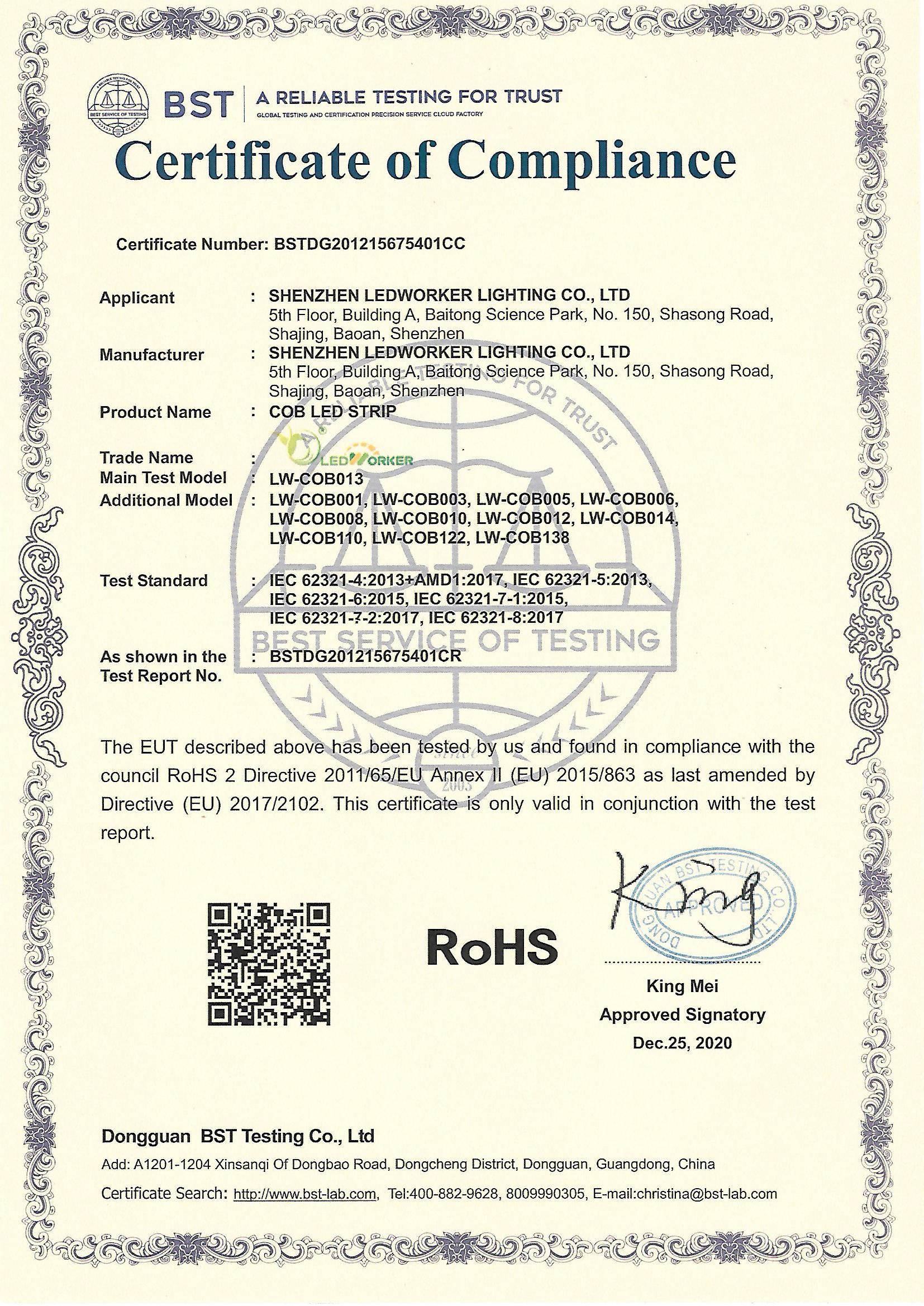

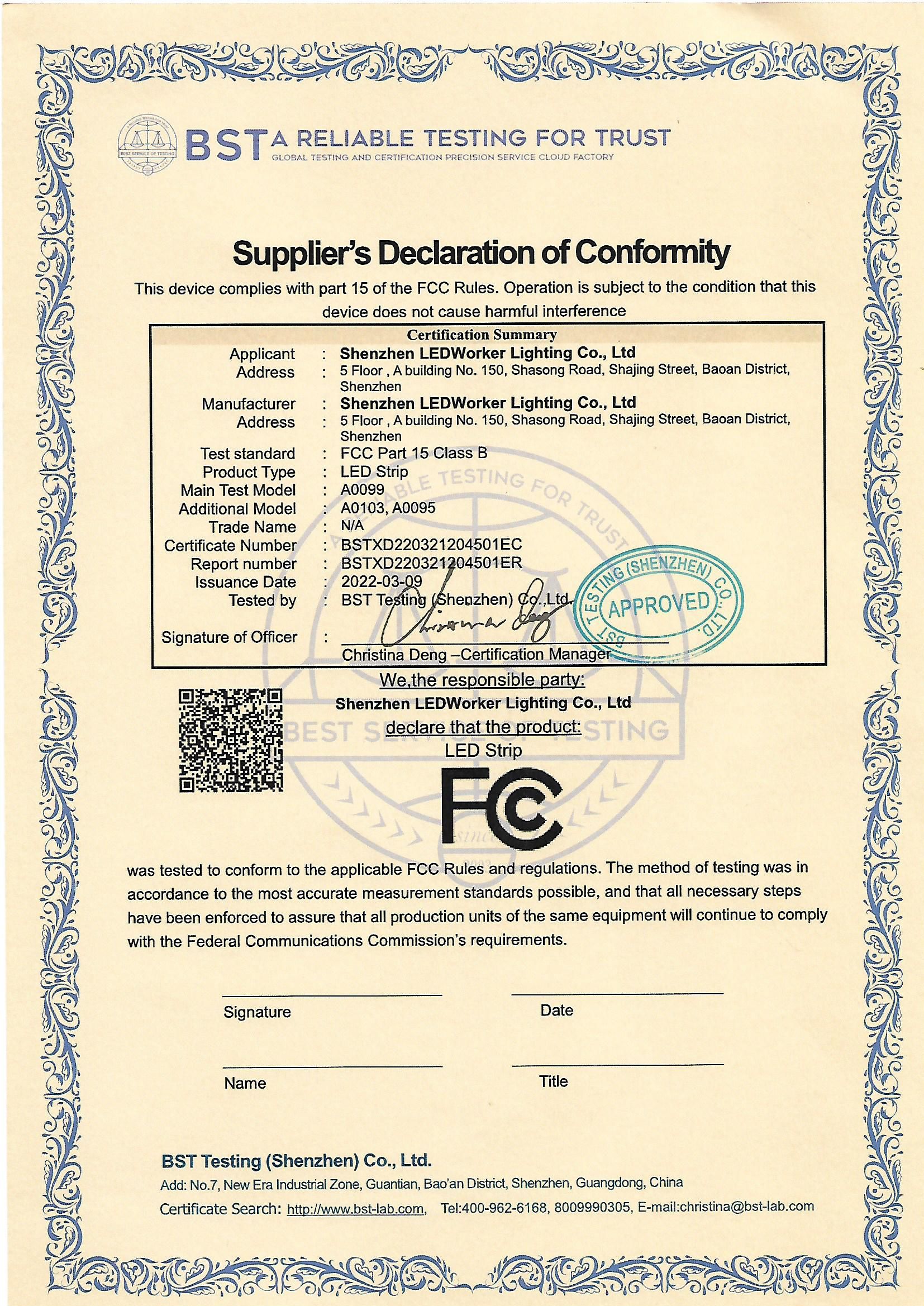

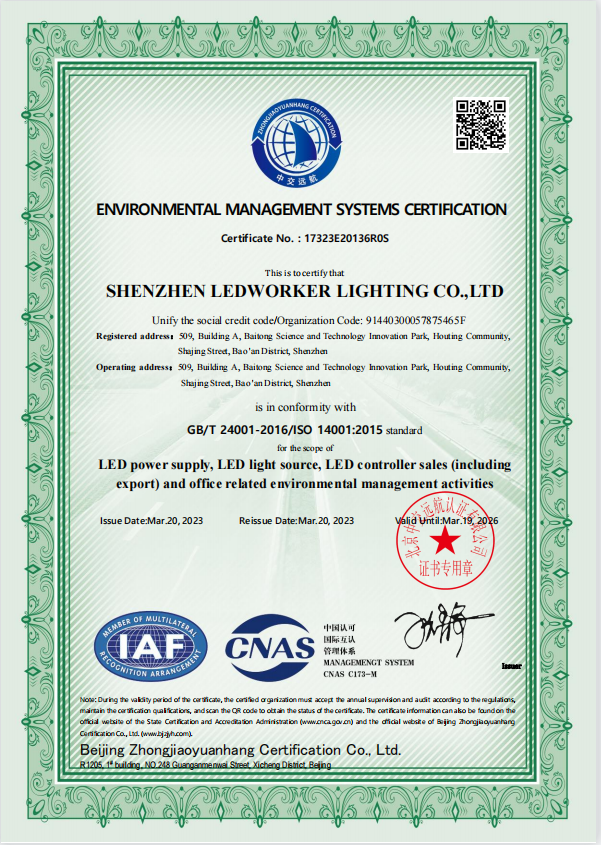

Certifications at LedWoker

At LEDWORKE, we are committed to our core values of customer-centricity and quality-first. Our goal is to build a modern, large-scale, and international company, and to that end, we have obtained various certifications to guarantee the quality and reliability of our products.

Certifications include:

ISO9001: Quality Management System certification.

ISO14001: Environmental Management certification.

TUV: Certification for safety and quality.

Our single-color LED strips have passed the following certifications:

CE: Ensures that our products comply with EU safety, health, and environmental requirements.

ROHS: Certifies that our products are free from hazardous substances.

ETL: Recognizes product compliance to North American safety standards.

REACH: Guarantees that our products adhere to regulations concerning the safe use of chemicals in the EU.

UL: Ensures that our products meet rigorous safety standards, especially for the U.S. market.

Additionally, we can provide specific testing reports per customer requests, including:

Salt Spray Test Reports: For evaluating corrosion resistance.

ERP Test Reports: Related to energy consumption and performance.

LM80 Test Reports: For long-term lumen maintenance.

EN 62471: Compliance with blue light hazard standards.

Testing

As a professional LED manufacturer, LedDesignsPro ensures that all of our LED strips undergo rigorous testing to guarantee top-notch quality and reliability. Our products are subjected to repeated cycles of thermal shock, high temperature and humidity storage, normal temperature aging, high humidity heat aging, and twist testing. Additionally, we utilize the Spektron coating integrating sphere to accurately measure the luminous flux (LM value) of our LED strips, maintaining strict quality control throughout the production process.

Below are the specific testing conditions, cycles, judgment criteria, and the equipment used:

| Test Item | Test Conditions | Duration/Cycle | Judgment Condition | Use Equipment |

|---|---|---|---|---|

| Thermal Shock | –40℃ 30min ↑↓ 5sec 100℃ 30min | 200 cycles | No cracked glue, no dead light | Hot and cold shock box |

| Humidity Heat Storage | Ta=85℃, RH=85%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and humidity box |

| Life Test | Ta=25℃, Rated voltage | 1000 hours | Luminous decay ≤3%, no cracked glue, no dead light | Room temperature aging seat |

| High Humidity Heat Life Test | 60℃, RH=90%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and high humidity aging box |

| Twist Test | 0.5M fixed at both ends, twisted 360°/cycle | 300 cycles | No dead light, no cracked glue | Distortion test machine |

Why Wholesale LED Strip In Bulk From Us

Choosing to wholesale LED strips from LedWoker comes with numerous benefits designed to meet the needs of your business:

Quality and Safety

At LedWoker, we prioritize quality and safety. All of our LED strips are manufactured using the finest materials and undergo rigorous testing to ensure they meet the highest standards. Every product is certified with CE and RoHS certifications, guaranteeing that our LED strips are both safe and reliable for a variety of applications.

Competitive Pricing

By producing our own LED chips and controlling every step of the manufacturing process, we are able to offer our products at highly competitive prices. This allows you to maximize your profit margins without compromising on quality.

Customizable Solutions

We understand that different projects have unique requirements. That’s why we offer comprehensive customization options, including LED density, PCB width, waterproofing levels, and color temperature. Whatever your project demands, we can deliver LED strips tailored to your exact specifications.

Production Capabilities

With our advanced manufacturing facilities and high production capacity, LedDesignsPro is equipped to handle bulk orders with ease. Whether you need thousands of meters for a large commercial project or a specific design for a niche market, we have the capacity to meet your demands efficiently and on time.

Fully Support

Our commitment to excellent customer service doesn’t end with the sale. We offer 24/7 support to ensure that your wholesale experience is seamless from start to finish. Our team is always ready to assist you with any inquiries, provide technical support, or help with logistics to ensure timely delivery.

Proven Track Record

We have built long-term relationships with clients worldwide, including well-known brands and large-scale distributors. Our consistent product quality, reliable service, and flexible solutions have earned us a reputation as a trusted supplier in the LED lighting industry.

FAQs

Here are top asked questions, feel free to contact us for more details.

Yes, the Cut-Free LED strip can be cut anywhere without affecting its functionality. The remaining strip can still work normally. You can use our solder-free connectors to attach a power cable to the cut portion.

LED strips have marked cut lines on the PCB pads. You can cut along these lines, as indicated. Cut-Free strips, however, can be cut anywhere.

For regular strips, cut evenly along the marked lines to avoid circuit damage. Cut-Free strips can be cut anywhere without risk.

Yes, with a compatible controller.

Use connectors or solder to reconnect them.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.