Mini Cutting Neon LED Strip

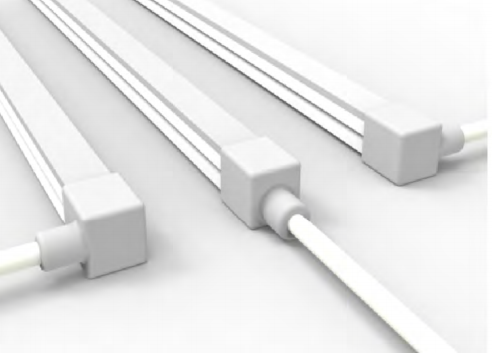

- Professionally designed structure for smooth, uniform lighting with excellent color temperature consistency and no visible dots.

- Resistant to yellowing, aging, high and low temperatures, suitable for demanding indoor and outdoor environments.

- Corrosion-resistant, able to withstand weak acids and alkaline salts.

- Verified waterproof with an IP67 rating for reliable outdoor use.

- Highly flexible, resistant to bending and stretching, easy to shape, and convenient for transportation.

- Cuttable at each LED, allowing for precise customization.

- Made of silicone, available in integrated extrusion and tubing options.

- Light emission options include front-emitting, side-emitting, and 360-degree illumination.

- Customizable in PCB width, voltage, power, color temperature, CRI, and length to meet project-specific needs.

Mini Cutting Neon LED Strip Supplier & Manufacturer

Shenzhen LEDWorker Lighting Co., Ltd is Located in Shenzhen City , established in 2012 . It has five fully automatic production lines. Monthly capacity of single product is 1 million meters to Handle Bulk Orders of Standard Led Strips and Various Forms of OEM & ODM LED Strip Lights.

We understand the importance how to provide the suitable products to help you earn the market. You need more than a supplier, We hope to establish long term business relationship and get the win win situation.

With sucessful experience of the support our customer and let them to be the No.1 in the market. We have confident to offer a very suitable products that will satisfy your requirements. If you have any request pls contact with our sales team, they will 24 hours 7 days working for you and give you one stop purchase experience.

What is Mini Cutting Neon LED Strip

The Mini Cutting Neon LED Strip is a highly flexible neon light strip designed for precise, small-scale cutting. Unlike conventional neon strips, which typically have cutting intervals of 25mm or 50mm, the Mini Cutting Neon LED Strip can be cut at 1mm intervals without impacting its light performance. It is available with COB or SMD chips and features single-LED cutting, allowing for maximum customization and adaptability to fit various lighting requirements and designs.

How to Produce LED Neon Flex Lights

We use two different methods to manufacture neon flex lights. The first method involves independently producing the neon casing and then inserting the LED strip into the pre-made casing. In the second method, the LED strip is placed in our integrated extrusion machine, where it is fully molded during the production process.

1. Inserting LED Strips into Neon Sleeves:

- First, the LED strips and neon sleeves are manufactured separately.

- The LED strip is then inserted into the dual-extrusion three-color molded sleeve, with end caps added to create a complete neon flex light.

- The high-transparency material of the sleeve helps control light loss, ensuring a higher light transmission rate and more vibrant color output.

- The sleeve is designed to protect the LED strip, preventing it from shifting or moving during installation or transport, which reduces the risk of damage. This flexibility allows the neon flex lights to be bent and twisted without harming the internal components.

- Customization is possible in terms of length, color schemes, and voltage, making it highly versatile.

2. Integrated Extrusion Molding:

- The second method involves fully integrating the LED strip and the silicone material during production, creating a single cohesive unit.

- There are two types of extrusion:

- Single-color extrusion: The silicone and LED strip are extruded together in one process, with the base typically being white.

- Dual-color extrusion: This is done in two stages—the base and the light-emitting surface can be colored to match specific design needs.

- When the base is white, it helps to focus light on the emitting surface. When the base is black, the surface appears brighter, and the overall design can seamlessly blend with the background for concealed lighting.

Customization:

- The extrusion process allows for extensive customization, including different colors for the base and surface. For example, the light body can be black, which hides the fixture when the lights are off but still produces bright light when switched on.

Why Choose Mini Cutting Neon LED Strip?

The Mini Cutting Neon LED Strip is an excellent choice due to its compact size, flexibility, waterproof nature, and resistance to aging, making it ideal for various custom lengths and shapes in intricate designs or confined spaces. Unlike regular neon strips, which usually can't be freely cut, the Mini Cutting Neon LED Strip offers greater flexibility with its easy cutting capability at any point, avoiding dark spots and simplifying installation without pre-measurement.

Compared to traditional glass neon lights, which typically last around 10,000 hours, LED Neon Flex has a much longer lifespan, up to 50,000 hours, making it a more durable and cost-effective option.

Available in various styles tailored to project requirements, including options in:

- Color: Choose from red, blue, green, purple, pink, and even custom colors like ice blue.

- Brightness: Options range from 100LM/W to 200LM/W for high brightness at low power.

- Size: Options like 410mm, 612mm, and 16*16mm.

- Light Emission Surface: Side, front, and 360-degree light emission.

- Shape: Traditional square or mushroom head for softened, dot-free illumination.

LED Neon Flex is made from silicone, which resists yellowing over time and ensures the strips remain durable. They can also be cut and customized to fit unique designs, making them perfect for dynamic environments.

With the use of controllers or remote controls, LED Neon Flex lights can be dimmed to suit different lighting needs, creating a vivid and colorful ambiance that attracts attention in commercial settings like shops and signs.

The strips are designed with cut marks on the back, allowing for easy cutting and connection using clear connectors. This makes it user-friendly and perfect for projects where precise lengths are required.

Mini Cutting Neon LED Strip Application

The Mini Cutting Neon LED Strip is widely used in LED lighting applications across various environments. It’s ideal for outdoor spaces such as museums, hotels, concert halls, gyms, schools, and bars, and it also serves as an excellent choice for indoor lighting applications. Common indoor uses include shopping center advertisements, backlighting, hallway lighting, decorative lighting, and amusement park accents. Recently, the demand for flexible LED neon lights on social media has led to increased use in apartment buildings, dorms, and private residences, where they provide outstanding lighting enhancements for outdoor and indoor areas alike.

- Museums, Hotels, and Music Halls: Neon Flex provides artistic lighting that enhances architectural features and creates a welcoming ambiance for visitors.

- Gyms and Schools: Neon Flex lighting is used for decorative and functional purposes, offering energy-efficient lighting in outdoor paths, sports areas, and entrances.

- Bars and Outdoor Venues: Its waterproof, flexible design makes it perfect for weather-exposed installations, like outdoor seating areas, signage, and decorative elements in bars and nightclubs.

- Shopping Centers: LED Neon Flex is extensively used for advertising, backlighting displays, and corridor lighting, adding a bright and dynamic touch to commercial environments.

- Decorative Lighting: It is an excellent choice for themed lighting in amusement parks, cinemas, and indoor attractions.

With the rise of social media trends, Neon Flex has become popular in private homes, dorm rooms, and apartment complexes. It's often used to create custom lighting designs, offering a trendy way to illuminate walls, ceilings, or even outdoor areas like balconies and patios.

Wholesale LED Mini Cutting Neon LED Strip By Series ?

We are a manufacturer of flexible LED Neon Lights, equipped with modern technology and a strong R&D and manufacturing capacity. We handle bulk orders for both standard LED neon strips and various OEM and ODM custom designs. We offer a wide range of neon strip types and sizes to meet your project needs.

Key Features of Our Manufacturing Services:

- Fast Delivery: Standard LED neon strip orders are delivered within 3-5 days, while OEM orders typically take 15-25 working days.

- Custom Design: We provide free product and packaging design, offering excellent project technical support and cost-effective solutions.

- Wide Range of Products: From standard neon lights to custom-made designs, we can produce different sizes, colors, and specifications.

LED Neon Flex type

(1)Vertical bending Series

Description: The vertical bending series allows the LED strip to bend up and down, with the bending direction following the light source. This design offers smooth, even brightness without visible spots, making it ideal for both indoor and outdoor applications. With IP67 waterproof rating and anti-yellowing silicone, it’s perfect for harsh environments like gardens, building contours, and landscape lighting.

Mini Cutting Neon LED Strip Index

Accessories for our Flexible LED Neon Light Strips:

(1),Controller

One of the best features of our flexible LED neon light strips is our variety of controllers. These controllers give you numerous capabilities for your lighting design, including dimming, fading, jumping, spinning, Madrix, Bluetooth, and APP control.

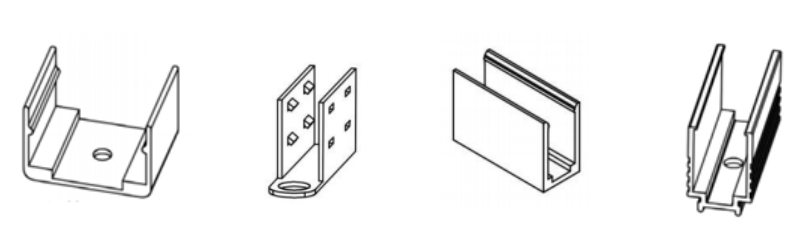

(2),End Caps

Our molding fits easily into end caps to make your installation, breakdown, and setup processes a lot faster. The end caps come in different styles, including right end cap, left end cap, straight end cap, tail end cap, and mounting clips.

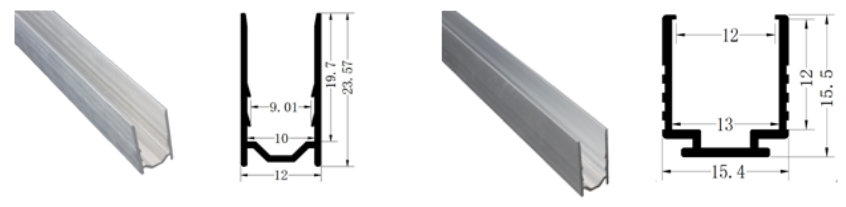

Installation Accessories:

- Clips: Varying sizes to match different LED neon light strips.

- Aluminum Profiles: Used to securely mount the neon strips onto surfaces.

- Serpentine Mounting Clip: Combines the flexibility of clips with the sturdiness of aluminum profiles.

Waterproof Connectors

When your next lighting design includes water features, or outdoor displays, take advantage of our waterproof connectors. They are available in different sizes to ensure your flexible LED neon light strip is protected.

Custom LED Neon Flex

At LEDWorker, we offer specialized customization services for our LED Neon Flex products, allowing each client to tailor the product to meet unique requirements. Our customization options include:

-

LED Density: We can adjust the LED count per meter to achieve a specific lighting effect, improving the linear appearance with higher densities.

-

PCB Customization: Depending on the installation environment, we can adjust PCB widths and configurations to enhance brightness and heat dissipation. For specific designs, we also offer options like dual- or triple-row configurations and flexible "S-shape" PCBs.

-

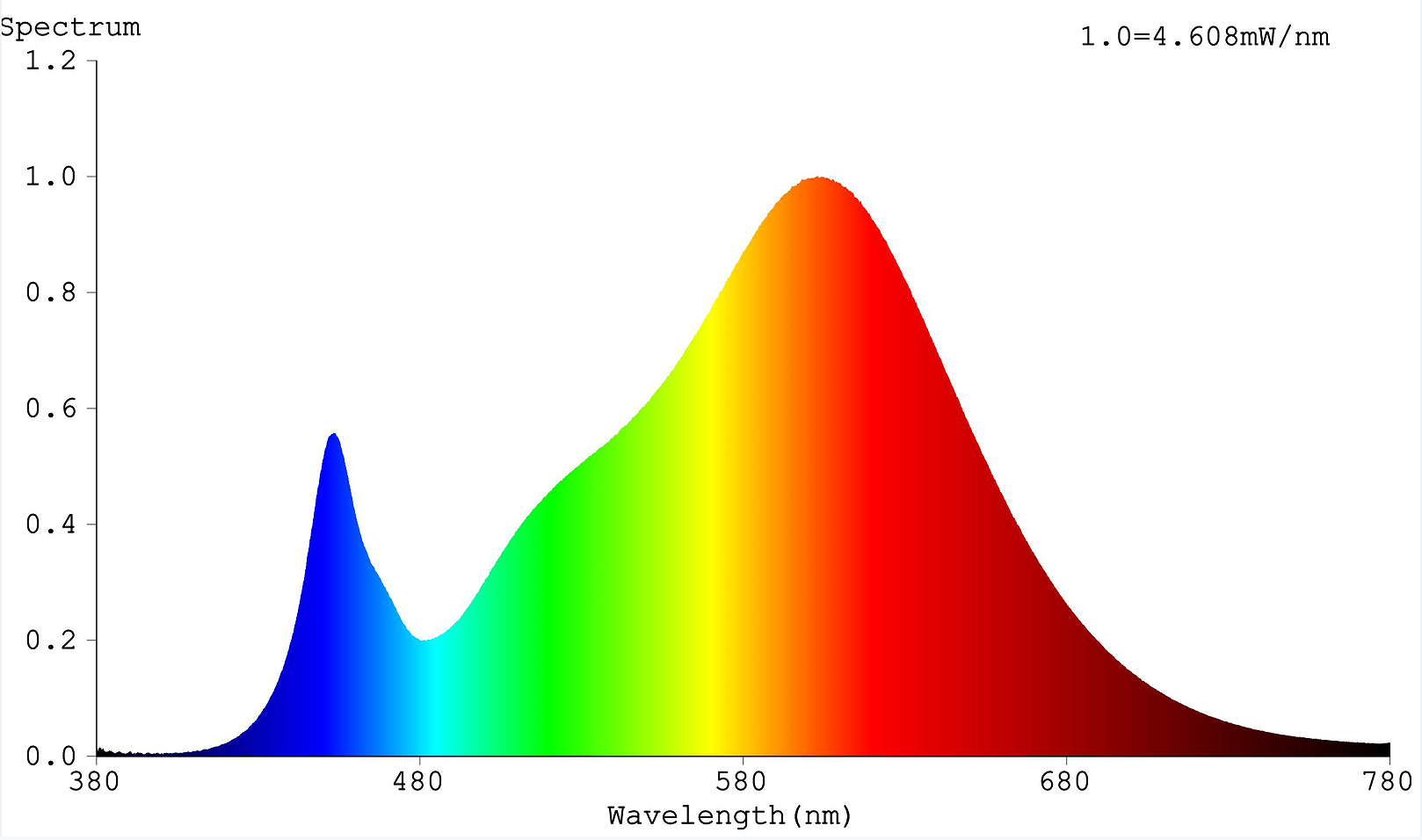

Color Temperature: Our standard color temperatures include 3000K, 4000K, 6000K, 8000K, and 10,000K. For projects requiring specific color outputs, we can further customize based on color coordinates (x, y values) to match any desired color spectrum.

-

Neon Flex Sizes: LEDWorker provides a range of standard sizes, but for projects needing unique dimensions, we offer OEM or ODM options, requiring mold customization to meet these specifications.

-

Packaging Customization: We offer tailored packaging solutions, including labels, bag designs, boxes, and display options, ensuring a complete and cohesive presentation.

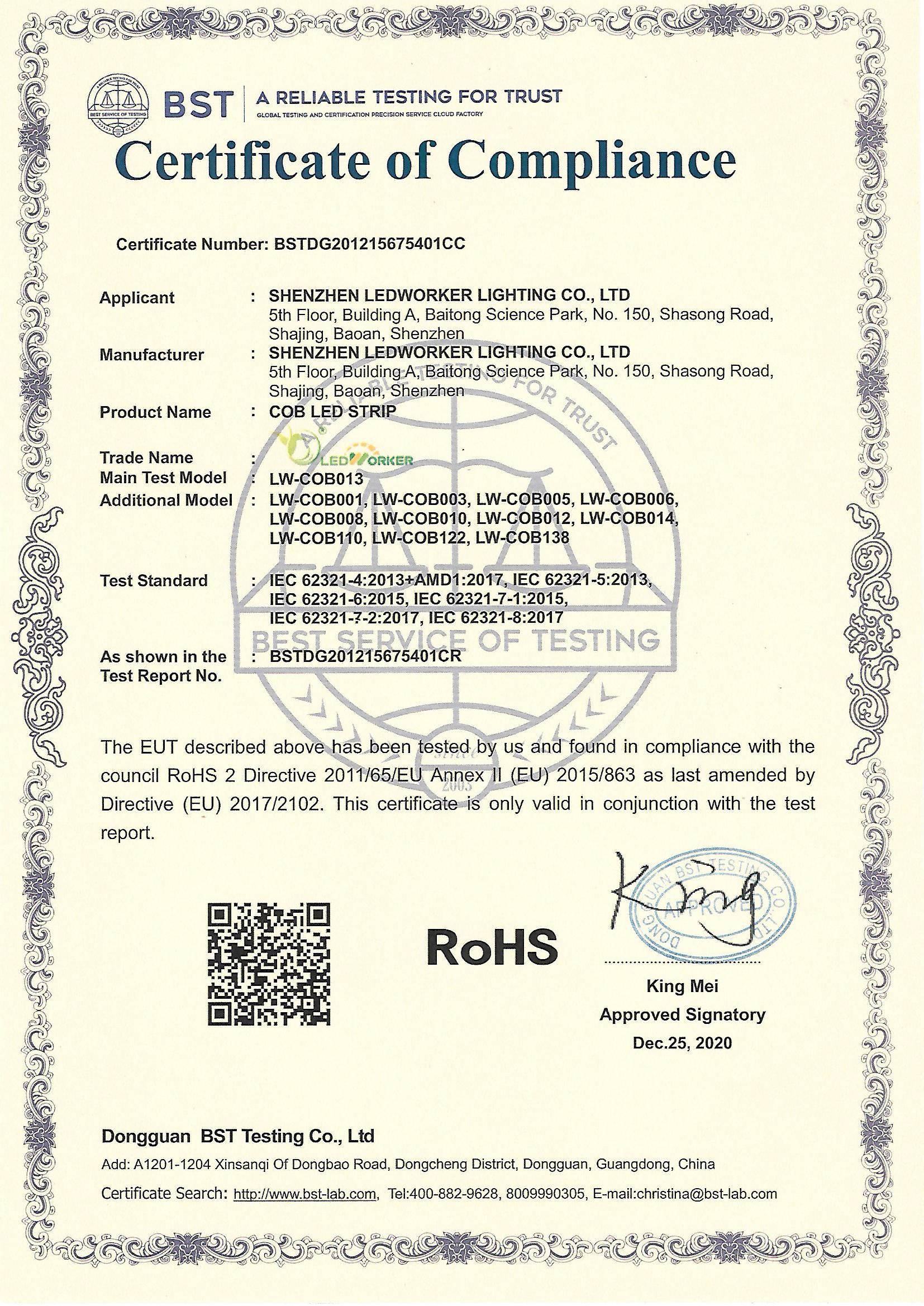

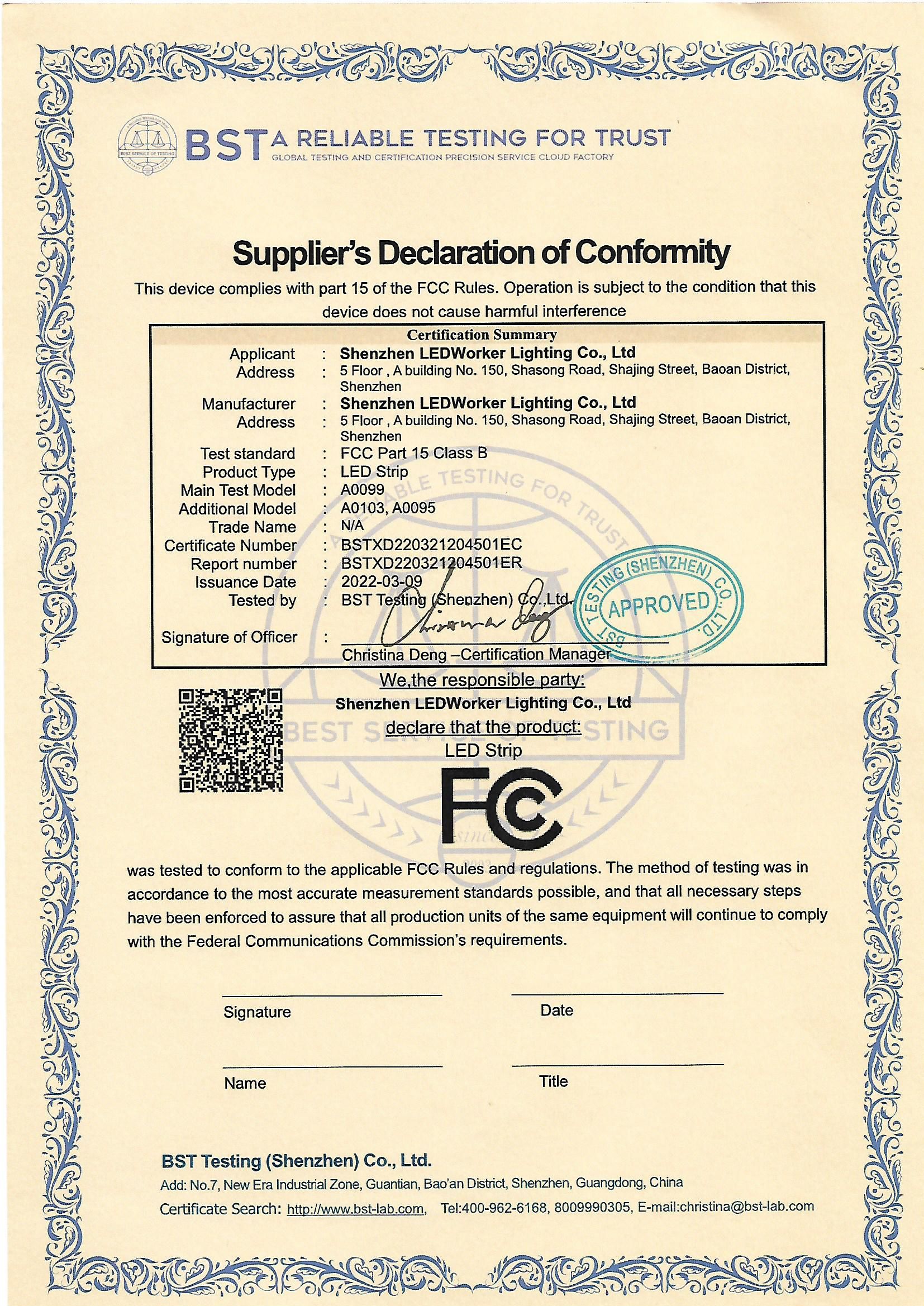

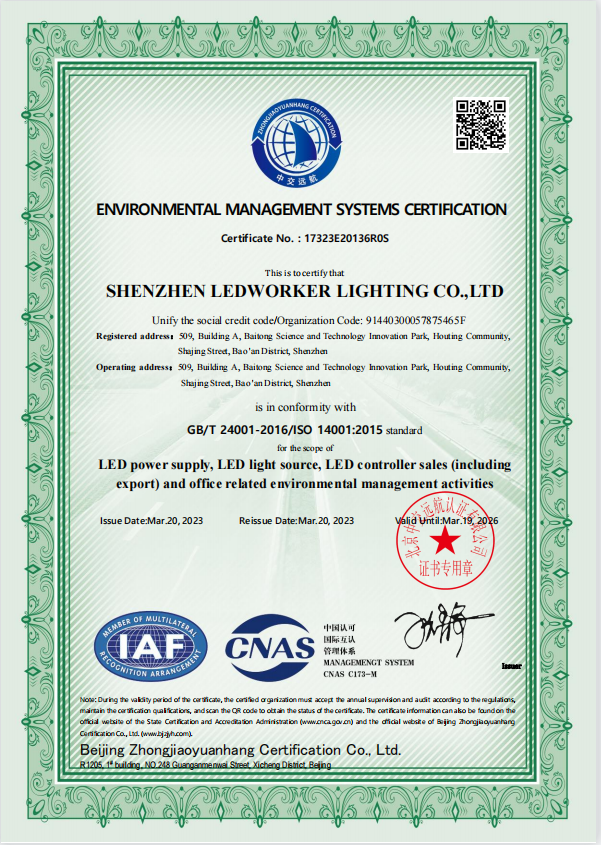

With experience providing OEM and ODM services to major brands and meeting ISO9001, CE, RoHS, and UL certifications, we’re committed to delivering high-quality, tailored solutions for each project. If you’re interested, our sales team is available 24/7 to discuss your specific needs and provide a seamless buying experience.

Certifications at LedWoker

At LEDWORKE, we are committed to our core values of customer-centricity and quality-first. Our goal is to build a modern, large-scale, and international company, and to that end, we have obtained various certifications to guarantee the quality and reliability of our products.

Certifications include:

ISO9001: Quality Management System certification.

ISO14001: Environmental Management certification.

TUV: Certification for safety and quality.

Our single-color LED strips have passed the following certifications:

CE: Ensures that our products comply with EU safety, health, and environmental requirements.

ROHS: Certifies that our products are free from hazardous substances.

ETL: Recognizes product compliance to North American safety standards.

REACH: Guarantees that our products adhere to regulations concerning the safe use of chemicals in the EU.

UL: Ensures that our products meet rigorous safety standards, especially for the U.S. market.

Additionally, we can provide specific testing reports per customer requests, including:

Salt Spray Test Reports: For evaluating corrosion resistance.

ERP Test Reports: Related to energy consumption and performance.

LM80 Test Reports: For long-term lumen maintenance.

EN 62471: Compliance with blue light hazard standards.

Testing

As a professional LED manufacturer, LedDesignsPro ensures that all of our LED strips undergo rigorous testing to guarantee top-notch quality and reliability. Our products are subjected to repeated cycles of thermal shock, high temperature and humidity storage, normal temperature aging, high humidity heat aging, and twist testing. Additionally, we utilize the Spektron coating integrating sphere to accurately measure the luminous flux (LM value) of our LED strips, maintaining strict quality control throughout the production process.

Below are the specific testing conditions, cycles, judgment criteria, and the equipment used:

| Test Item | Test Conditions | Duration/Cycle | Judgment Condition | Use Equipment |

|---|---|---|---|---|

| Thermal Shock | –40℃ 30min ↑↓ 5sec 100℃ 30min | 200 cycles | No cracked glue, no dead light | Hot and cold shock box |

| Humidity Heat Storage | Ta=85℃, RH=85%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and humidity box |

| Life Test | Ta=25℃, Rated voltage | 1000 hours | Luminous decay ≤3%, no cracked glue, no dead light | Room temperature aging seat |

| High Humidity Heat Life Test | 60℃, RH=90%, Rated voltage | 1000 hours | Luminous decay ≤10%, no cracked glue, no dead light | High temperature and high humidity aging box |

| Twist Test | 0.5M fixed at both ends, twisted 360°/cycle | 300 cycles | No dead light, no cracked glue | Distortion test machine |

Why Wholesale Mini Cutting Neon LED Strip In Bulk From Us

Choosing to wholesale Mini Cutting Neon LED Strip from LedWoker comes with numerous benefits designed to meet the needs of your business:

Quality and Safety

At LedWoker, we prioritize quality and safety. All of our LED strips are manufactured using the finest materials and undergo rigorous testing to ensure they meet the highest standards. Every product is certified with CE and RoHS certifications, guaranteeing that our LED strips are both safe and reliable for a variety of applications.

Competitive Pricing

By producing our own LED chips and controlling every step of the manufacturing process, we are able to offer our products at highly competitive prices. This allows you to maximize your profit margins without compromising on quality.

Customizable Solutions

We understand that different projects have unique requirements. That’s why we offer comprehensive customization options, including LED density, PCB width, waterproofing levels, and color temperature. Whatever your project demands, we can deliver LED strips tailored to your exact specifications.

Production Capabilities

With our advanced manufacturing facilities and high production capacity, LedDesignsPro is equipped to handle bulk orders with ease. Whether you need thousands of meters for a large commercial project or a specific design for a niche market, we have the capacity to meet your demands efficiently and on time.

Fully Support

Our commitment to excellent customer service doesn’t end with the sale. We offer 24/7 support to ensure that your wholesale experience is seamless from start to finish. Our team is always ready to assist you with any inquiries, provide technical support, or help with logistics to ensure timely delivery.

Proven Track Record

We have built long-term relationships with clients worldwide, including well-known brands and large-scale distributors. Our consistent product quality, reliable service, and flexible solutions have earned us a reputation as a trusted supplier in the LED lighting industry.

FAQs

Here are top asked questions, feel free to contact us for more details.

Our smallest neon flex size is 3mm x 5mm.

Yes, Cut Free Neon Flex Lights are designed to be cut anywhere along the strip, making them easy to adjust.

Whether it can be cut depends on the LED strip inside. The cut points on the neon flex are determined by the internal strip.

We provide clips and aluminum channels to secure the neon flex in place.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.