LED Strip Connector

- Solder-Free Design: These connectors are easy to use and allow for quick, solder-free connections, simplifying installation.

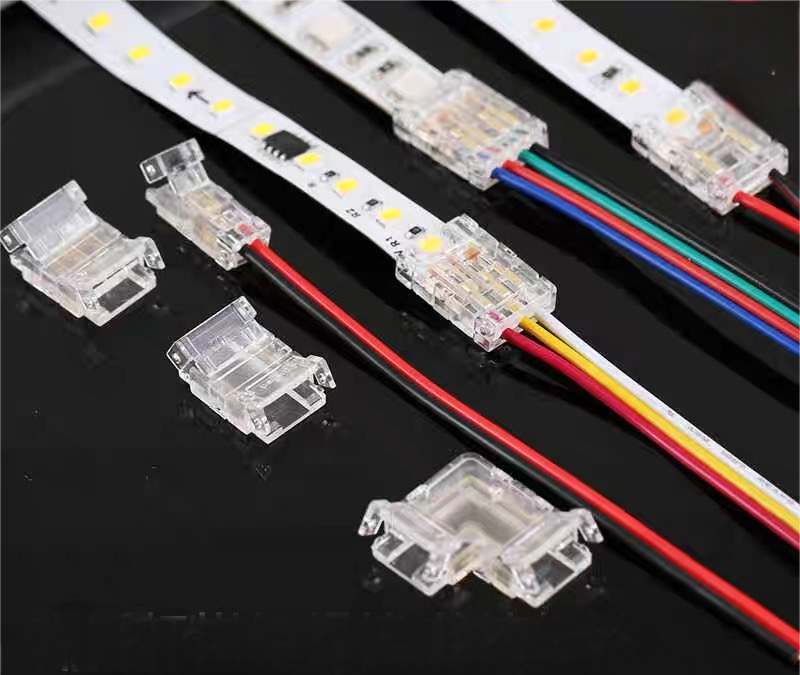

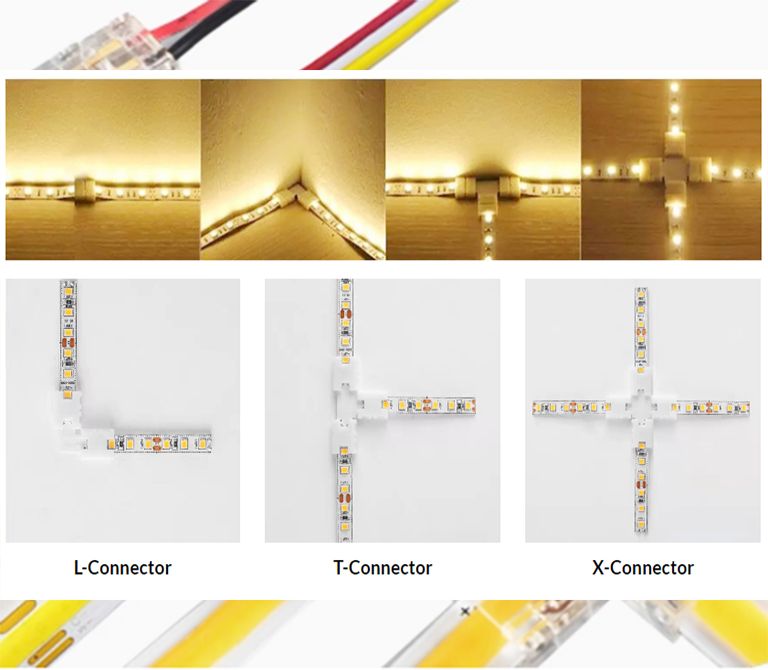

- Multiple Shapes Available: Connectors come in various shapes to suit different configurations, such as right-angle, cross, T-type, and inline connectors.

- Waterproof Options: Available in IP20, IP65, and IP67 ratings to accommodate both indoor and outdoor setups.

- Pin Options: They offer multiple pin configurations, including 2PIN, 3PIN, 4PIN, 5PIN, and 6PIN, making them compatible with single color, RGB, RGBW, and other LED strip types.

- Width Compatibility: Designed for LED strips of various widths, including 6mm, 8mm, 10mm, and 12mm.

- Flexible Connection Types: Options for single-side wire, double-side wire, and board-to-board connections provide flexibility for different installation needs.

What is LED Strip Connector?

An LED Strip Connector is an electrical component designed to help users seamlessly connect LED strips after cutting, enhancing ease of use and flexibility in configuration. Primarily made of a PCB board and a plastic shell with PINs, the connector establishes a conductive circuit to ensure consistent power flow across LED strips. This design simplifies installation and boosts connection stability, allowing users to customize LED setups without needing soldering skills.

Main Types of LED Strip Connectors:

LEDWorker Lighting Co., Ltd., based in Shenzhen and established in 2012, specializes in a complete range of waterproof and non-waterproof LED connectors. They offer rapid delivery times (3-5 days) and serve clients in over 200 countries with versatile products adaptable for different industry needs.

- Solder-Free Connectors: Simplify installation by enabling users to connect strips without soldering.

- Waterproof Connectors: With IP20, IP65, and IP67 options, suitable for different environments.

- Transparent Connectors: These provide a more discreet look while maintaining connection functionality.

- Various Configurations: Available in shapes like straight, T-type, cross, and right-angle connectors, plus options for single-side, double-side, or board-to-board connections.

Solder Free Connectors

Waterproof Connectors

Transparent Connectors

Various Configurations

LED Strip Connectors Overview

1. Non-Waterproof Series

-

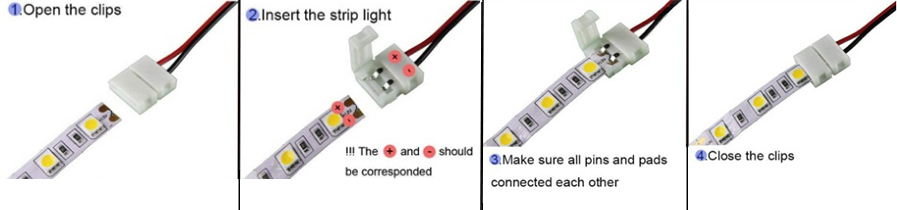

Solderless Connectors: A traditional connector with clips for each pin to hold LED strip pads securely. After cutting the LED strip, simply insert it into the connector to light up. Available in various configurations:

- Pin Configurations: 2-pin (single color), 3-pin (dual color), 4-pin (RGB), 5-pin (RGBW), and 6-pin (5-in-1).

- Shapes: Cross, L-shape, T-shape, single-ended, and double-ended.

- Styles: Non-Waterproof Middle Connector, Corner Connector, and Strip-to-Wire Connector.

Video Tutorial on Use

-

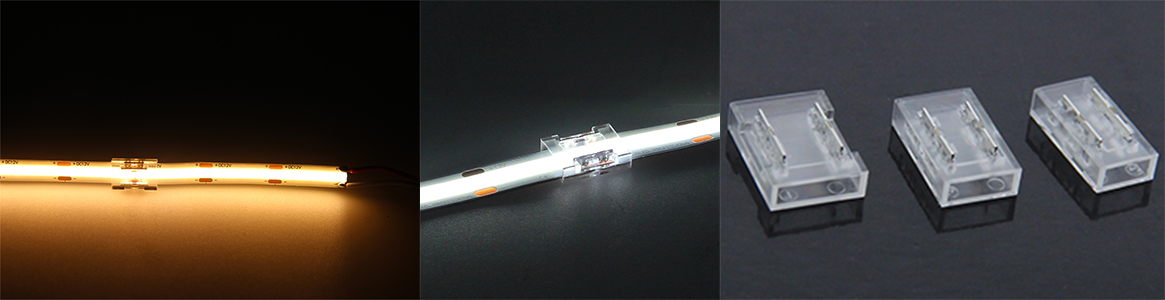

Transparent Connectors: Made of transparent plastic with pins, available in two main types:

- Type A (LED strip to wire) and Type B (LED strip to LED strip).

- Pin Options: 2 to 6 pins for various widths (6mm, 8mm, 10mm, 12mm).

- Styles: Non-Waterproof Middle Connector, Corner Connector, and Strip-to-Wire Connector.

Solderless vs. Transparent Connectors Comparison

-

Hippo Buckle Connectors: Popular for their range of compatibility, available in IP20 and IP65, with pins ranging from 2 to 6. Ideal for various strip widths and setups (strip-to-wire, strip-to-strip).

How to Use Hippo Buckle

-

Wire Connectors: Includes plug connectors and distribution boxes (1-to-2, 1-to-3, and 1-to-4). Designed for quick connections and efficient cable management.

2. Waterproof Series

Designed for waterproof LED strips, these connectors ensure stable operation in outdoor conditions:

- Pin Options: 2 to 6 pins for different strip configurations.

- Styles: Waterproof Middle Connector, Corner Connector, and Strip-to-Wire Connector, suitable for various widths (8mm, 10mm, 12mm).

Advantages and disadvantages of different connectors:

1. Solderless Connectors

- Advantages: Easy to use and available in a variety of styles, including different pin configurations (2-6 pins) and shapes (cross, L-shape, T-shape).

- Disadvantages:

- Only suitable for non-waterproof LED strips.

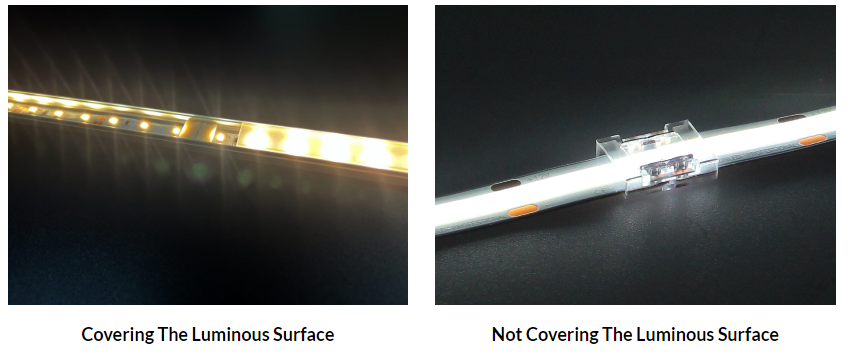

- Often covers one or two LEDs, which can create a small dark spot if used for under-cabinet lighting.

- Can become loose over time, especially if there’s external force or movement, due to the simple clip mechanism.

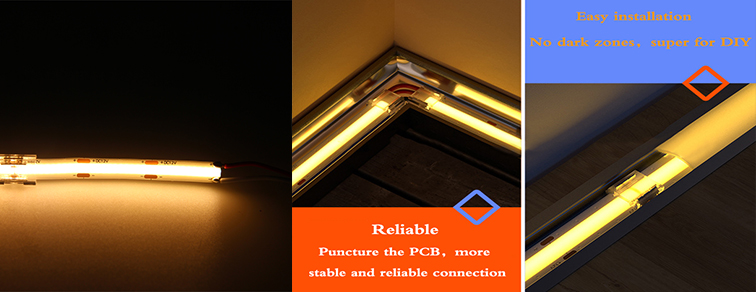

2. Transparent Connectors

- Advantages: Provides a firm connection by penetrating the PCB, which helps prevent disconnection. The transparent body allows light to pass through, creating a seamless effect without shadows or dark spots.

- Disadvantages: Primarily suited for indoor use unless specified otherwise for waterproofing.

3. Hippo Buckle Connectors

- Advantages: Available in waterproof (IP65) and non-waterproof versions. Compatible with various PCB widths from 5mm to 12mm, making them versatile. Offers a robust hold, stronger than solderless connectors.

- Disadvantages: Bulkier than transparent connectors, making it challenging to fit into narrow spaces, such as aluminum channels. Light transmission isn’t as clear as with transparent connectors, but still better than many solderless options.

4. Waterproof Connectors

- Advantages: Designed with a sealed structure, providing protection against moisture and suitable for outdoor applications. They ensure reliable operation in wet or humid environments.

- Disadvantages: Larger size due to sealing components, which may limit compatibility with narrow installation channels.

Why Choose LED Connector?

Choosing an LED connector can make LED strip installation quicker, easier, and more flexible. Here’s why it’s a popular choice:

LED connectors simplify the process by eliminating the need for soldering. Users don’t need specialized tools or skills to install LED strips, as connectors can be attached by hand. This not only saves time but also avoids the complexity involved in soldered connections, which typically require more tools and expertise.

LED connectors come in a range of styles to meet different needs. Options include waterproof and non-waterproof connectors, as well as multiple PIN configurations (e.g., 2-pin for single-color, 3-pin for RGB, etc.) and widths to match different LED strip specifications. This makes them suitable for various LED lighting applications, from indoor decor to outdoor installations.

Made from high-quality, corrosion-resistant, and heat-resistant materials, LED connectors are built for long-term use. They provide stable connections and can withstand different environmental conditions, enhancing the reliability and lifespan of the LED installation.

LED connectors offer simple maintenance. If a section of the LED strip fails, it’s easy to cut and replace only the affected part without disrupting the entire setup. Many connectors are designed for easy disconnection and reconnection, allowing for quick repairs and adjustments with minimal effort and cost.

To select a suitable LED strip connector, consider the following steps:

-

LED Strip Type:

- Identify the LED strip’s type based on the number of PINs required. Typically:

- Single-color strips need a 2-pin connector.

- Tunable white or dynamic color LED strips (such as RGB or RGBW) require 3-pin, 4-pin, or 5-pin connectors respectively.

- 5-in-1 LED strips use 6-pin connectors.

- Also, match the width of the connector to the width of your LED strip (usually 6mm, 8mm, 10mm, or 12mm).

- Identify the LED strip’s type based on the number of PINs required. Typically:

-

Usage Environment:

- For outdoor or humid conditions, choose waterproof options like hippo snap or waterproof connectors. If transparency is important (to avoid shading light), select clear waterproof connectors to maintain brightness.

-

Connector Type:

- Select a connection method suitable for your installation, including middle connectors, T, L, or X shapes, and options with single or double-sided cable connections to connect strips flexibly.

-

Confirm Requirements:

- If your LED setup has custom needs, consulting with a professional or a supplier can help. They can suggest the most compatible connectors and options.

Installation Guide:

- Solder-Free Connector: Cut the led strip to the appropriate position—> Peel off the tape of 3M adhesive about 1/4 inch—> Insert the two ends of the LED strip into the middle top position and snap it together—> Cover the cover—> Power on .

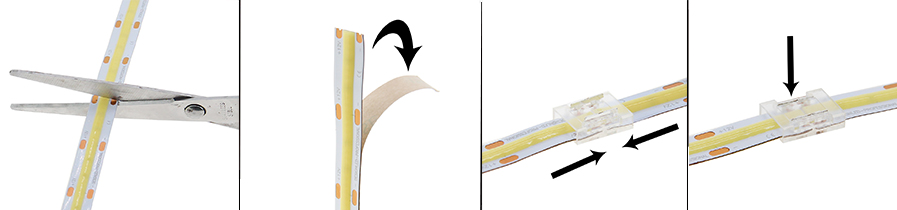

- Transparent Connector: The third one is the latest connector, this one is suitable for 2PIN regular led strip, cut the led strip to the proper position—> peel off the 3M adhesive tape about 1/4 inch—> two The end light strip is inserted into the middle top position—>Put the pin down, the led strip PCB board is penetrated—>Power on

1. Cut the COB on the cut mark. 2. Take the 3M tape out. 3.Put the strip with the connector and connect it together. 4.The installation is complete

- Hippo Snap Connector: The connection method of led strip and hippo buckle:Cut the led strip to the proper position—>Open strip end cover —> Place strip light on PIN —> Clamp cover slowly —> make sure all points are locked well

The connection method of led strip with cable:

Separate flat wire —> Place wire into groove —> clamp cover slowly —> make sure all points are locked well.

For visual guidance, watch this instructional video on connector installation: Watch Video.

Application

LED connectors are essential accessories for LED strip lights, known for their convenience, reliability, and flexibility. They play a crucial role in connecting LED strips in various lighting applications, from interior to exterior and decorative lighting, providing robust support for modern lighting solutions.

LED connectors are widely used in homes, retail spaces, and offices to connect LED strips, ensuring stable and even lighting. Their quick installation and removal make maintenance and replacement more efficient, enhancing user experience.

In outdoor environments like parks, plazas, and building facades, waterproof connectors are indispensable. They protect against moisture and harsh weather conditions, ensuring safe, stable operation of LED strips in landscape and urban lighting projects.

LED connectors facilitate easy connection and disconnection for decorative applications, such as holiday decorations and signage. This flexibility simplifies the setup and removal of lighting decorations, meeting both short-term and long-term needs.

Why Choose LEDWorker?

Choosing to wholesale LED strips from LedDesignsPro comes with numerous benefits designed to meet the needs of your business:

Quality and Safety

At LedDesignsPro, we prioritize quality and safety. All of our LED strips are manufactured using the finest materials and undergo rigorous testing to ensure they meet the highest standards. Every product is certified with CE and RoHS certifications, guaranteeing that our LED strips are both safe and reliable for a variety of applications.

Competitive Pricing

By producing our own LED chips and controlling every step of the manufacturing process, we are able to offer our products at highly competitive prices. This allows you to maximize your profit margins without compromising on quality.

Customizable Solutions

We understand that different projects have unique requirements. That’s why we offer comprehensive customization options, including LED density, PCB width, waterproofing levels, and color temperature. Whatever your project demands, we can deliver LED strips tailored to your exact specifications.

Production Capabilities

With our advanced manufacturing facilities and high production capacity, LedDesignsPro is equipped to handle bulk orders with ease. Whether you need thousands of meters for a large commercial project or a specific design for a niche market, we have the capacity to meet your demands efficiently and on time.

Fully Support

Our commitment to excellent customer service doesn’t end with the sale. We offer 24/7 support to ensure that your wholesale experience is seamless from start to finish. Our team is always ready to assist you with any inquiries, provide technical support, or help with logistics to ensure timely delivery.

Proven Track Record

We have built long-term relationships with clients worldwide, including well-known brands and large-scale distributors. Our consistent product quality, reliable service, and flexible solutions have earned us a reputation as a trusted supplier in the LED lighting industry.

FAQs

Here are top asked questions, feel free to contact us for more details.

No. different led strip need different connectors.

Yes, can be. Just cut the broken LED. And use connect to make it together again.

Normally not more than 3 meters.

Single color led strip, RGB led strip, 4IN1 led strip, 5IN1 led strip, Addressable led strips.

Yes, it can be. Just make sure the aluminum profile is big enough for the connector.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.