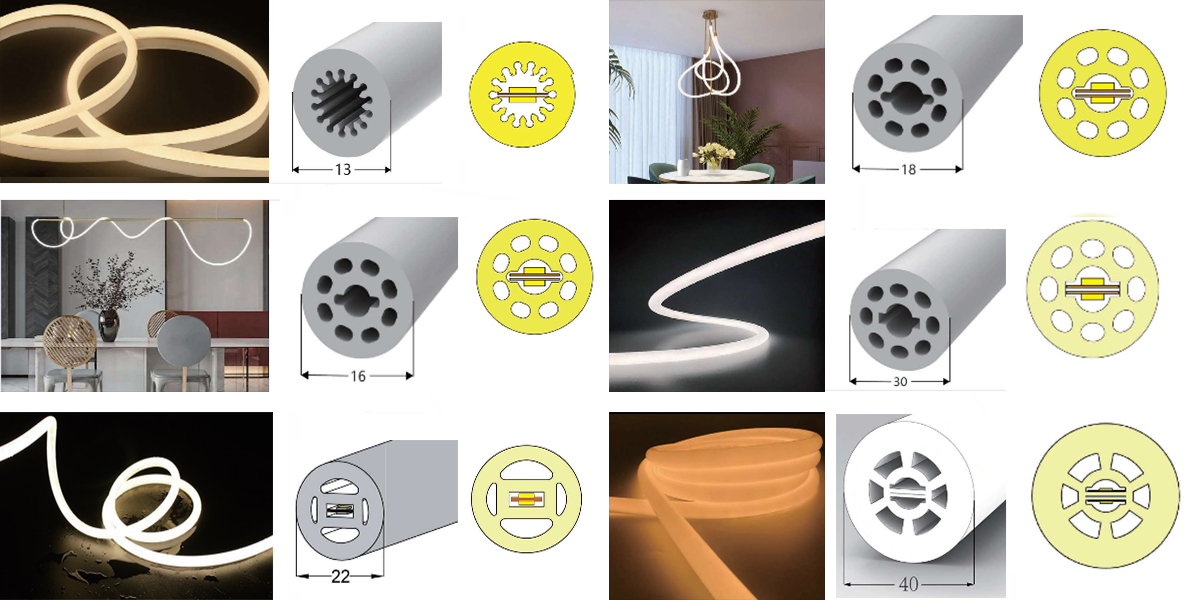

01. Multiple Size Options

Our 360 Degrees Flex Neon LED Strip are available in a variety of sizes and colors, offering versatile designs to suit different projects.

Available sizes include:φ13mm、φ16mm、φ18mm、φ20mm、φ22mm、φ30mm

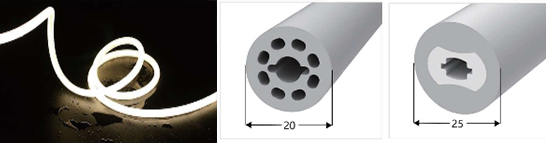

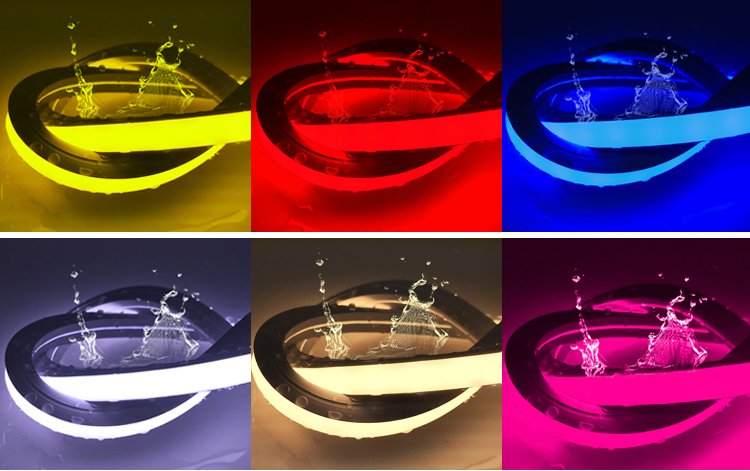

02. 360-Degree Neon Light Strips

Our round neon strips feature a 360-degree full illumination design, providing bright and uniform lighting with

excellent color temperature consistency. Available in:

360-Degree Illumination

270-Degree Illumination

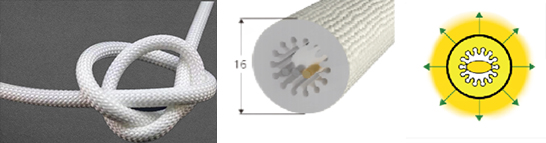

03. Braided 360-Degree Neon Light Strips

In addition to silicone neon strips, we offer braided round neon strips made with premium braided materials.

Durability & Flexibility: Ideal for installations requiring bending or custom shapes.

Customizable: Perfect for unique project requirements.

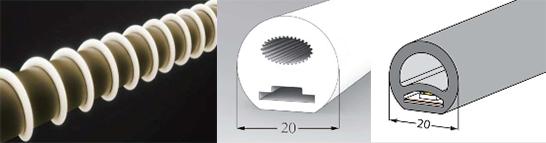

04.Extrusion & Tubing Processes

Tubing Process: Neon tubing is created separately, and the LED strip is inserted afterward.

Extrusion Process: The LED strip is fully encapsulated during the production stage using one-piece molding machines.

Video: Watch Here

05.Silicone Material

Our neon strips are made with silicone, which offers superior resistance to:Yellowing, aging, and extreme temperatures.

This makes it ideal for outdoor use. While PVC is a cost-effective option, it has lower resistance to aging and yellowing over time.

06.Waterproof Connectors

Male and female connectors are designed for easy manual connection while ensuring excellent waterproof performance.

These connectors make the entire strip water-resistant and secure for outdoor use.

07. IP67 Waterproof Rating for Outdoor Use

The flexible neon LED strips are rated IP67, suitable for outdoor installations. During outdoor installation,

attention must be paid to waterproofing, aging, and thermal expansion/contraction due to adverse weather conditions.

- Primary Waterproofing: At our manufacturing facility, we implement waterproof treatments tailored to the molding process. For single-shot molding, waterproof connectors and stainless steel rings are added to seal open ends, enhancing durability.

- Secondary Waterproofing: If secondary molding is requested, additional waterproofing measures are taken during packing as per the custom order. Special care is given to interface positions to ensure robust waterproofing.

For more detailed waterproofing instructions and options, feel free to reach out to our technical team.

08. Customizable Lengths

We offer tailored length options based on customer requirements. The shortest possible length is 1cm, while the longest continuous length can

reach 20–30 meters, powered from both ends to prevent voltage drops. This customization ensures optimal performance for various projects and applications.

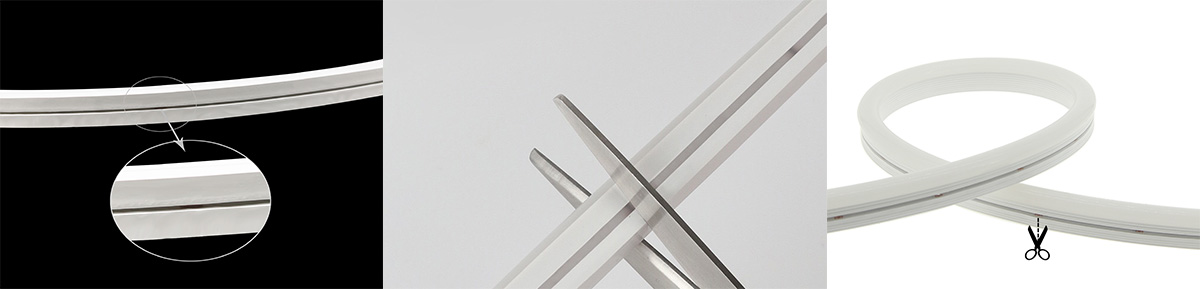

09. Cuttable and Flexible Design

The neon LED strip features cutting lines on the back, allowing precise and convenient cutting to fit your specific needs. Its flexibility makes

it ideal for installation on various shapes and curves, enabling seamless integration into diverse spaces.

Watch our demo video: Installation and Customization Guide

For further customization inquiries, feel free to contact us!