SMD2018 LED Strip

- Stable SMD LED Chips: Replaces flip-chip technology for greater stability.

- 30% Improved Light Efficiency: Provides more even and efficient lighting.

- Enhanced Color Consistency: SMD light source offers broader, consistent color quality.

- Cuttable Design: Can be trimmed to desired lengths to fit various needs.

- Easy Installation: Simple structure of 2018 strip supports flexible, user-friendly installation.

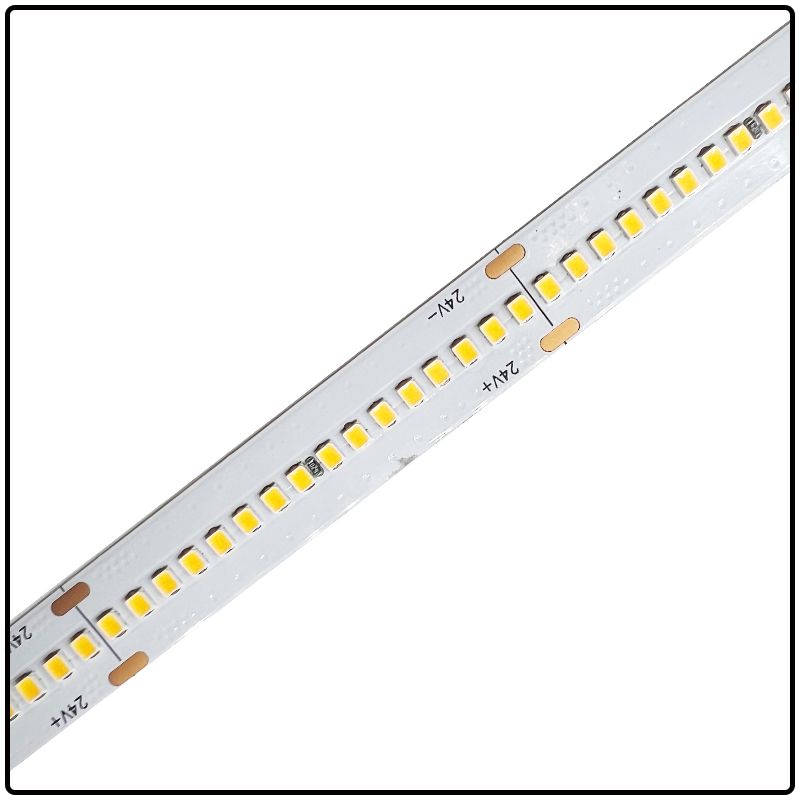

What is 2018 LED Strip?

The SMD2018 LED strip is a proprietary design with uniquely sized LED chips developed in-house. This chip size provides a larger light-emitting area, featuring key advantages like high light efficiency, excellent color consistency, and an efficiency of up to 130lm/W.

2018 LED Strip Specifications

Product Features

- LED Count: Options for 308 or 320 LEDs.

- PCB Width: Available in 5mm, 8mm, and 10mm options.

- Color Temperature: Available options include 2700K, 3000K, 4000K, 6000K, 8000K, and 10000K.

- Color Rendering Index (CRI): Options include >80, >90, and >95.

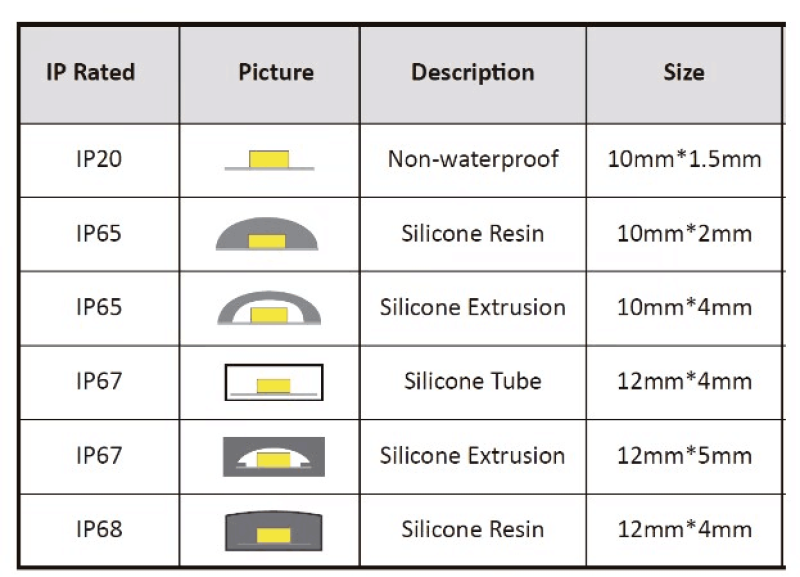

- Waterproof Level: Available in IP20, IP65, IP67, and IP68.

Product Specification

|

Advantage: |

1,320pcs SMD 2018 LED Strip |

2, 308pcs SMD 2018 LED Strip |

|

Part NO: |

A0323 |

A04111 |

|

LED Qty: |

320pcs per meter |

308pcs per meter |

|

CRI (RA) |

>90 |

>90 |

|

PCB Width IP20: |

10mm |

10mm |

|

Input Voltage: |

DC24V |

DC24V |

|

Watts: |

14W |

14W |

|

Luminous Flux: |

150LM / W |

150LM / W |

|

Color: |

2700/3000/4000/6000K |

2700/3000/4000/6000K |

|

PCB color: |

White |

White |

|

IP Grade: |

IP20 |

IP20 |

|

Operating temperature: |

.-25 to 45℃ |

.-25 to 45℃ |

|

Beam angle: |

120 degree |

120 degree |

|

Certification: |

CE; RoHS |

CE; RoHS |

|

Max Run: |

5M |

5M |

|

Min Run: |

24V 50mm |

24V 45.45mm |

|

|

|

Products Details

01.Resistors

Features reflow soldering technology, low-temperature reflow soldering, fully smooth welding, ensuring environmental friendliness and durability.

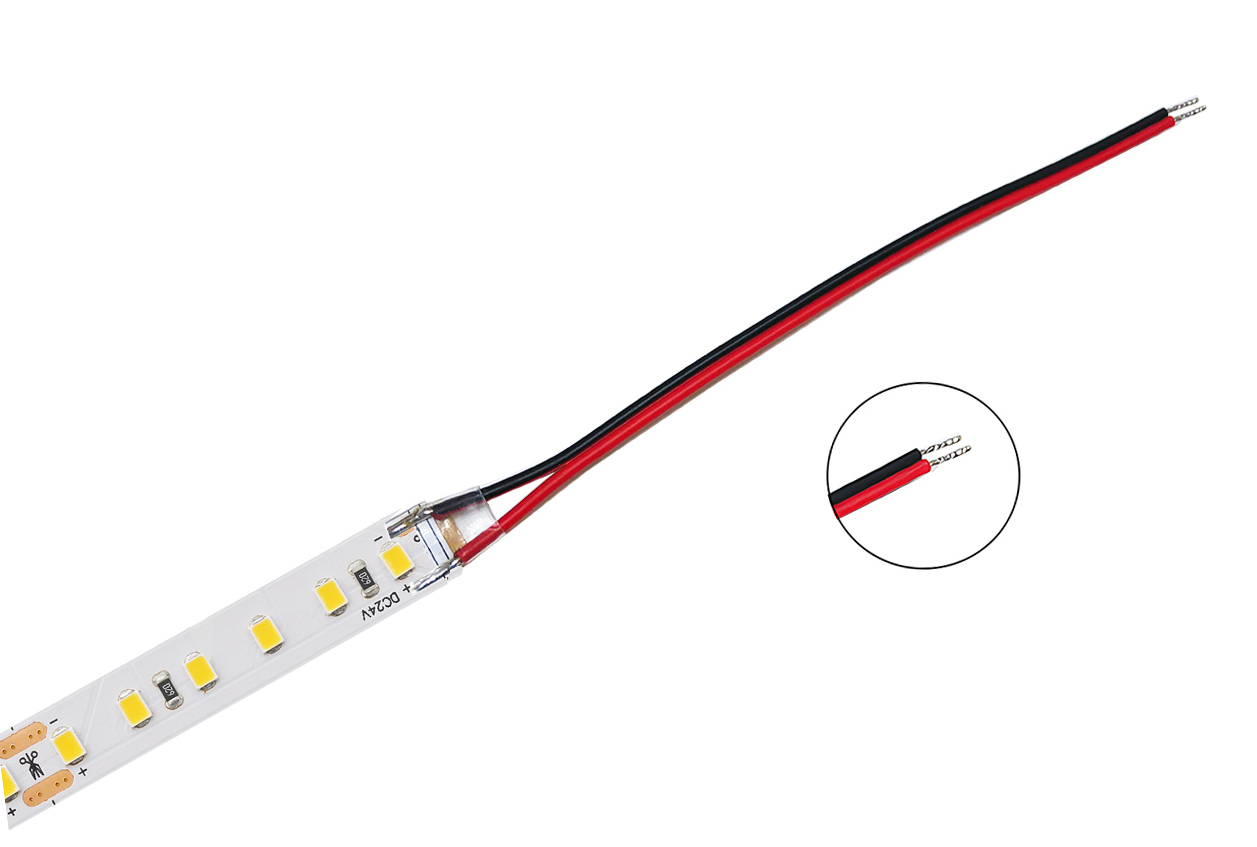

02. 22AGW PURE COPPER WIRE

Robust welding with high current capacity PVC wire.

Uses FPC as a flexible substrate, which can be bent freely without breaking and is easy to shape.

SAFETY INFORMATION

- Consult an electrician before performing any electrical work.

- Do not apply mechanical pressure to powered devices or components.

- Ensure correct electrical polarity.

- Observe ESD (Electrostatic Discharge) precautions during assembly.

- Installation should be conducted by a qualified electrician.

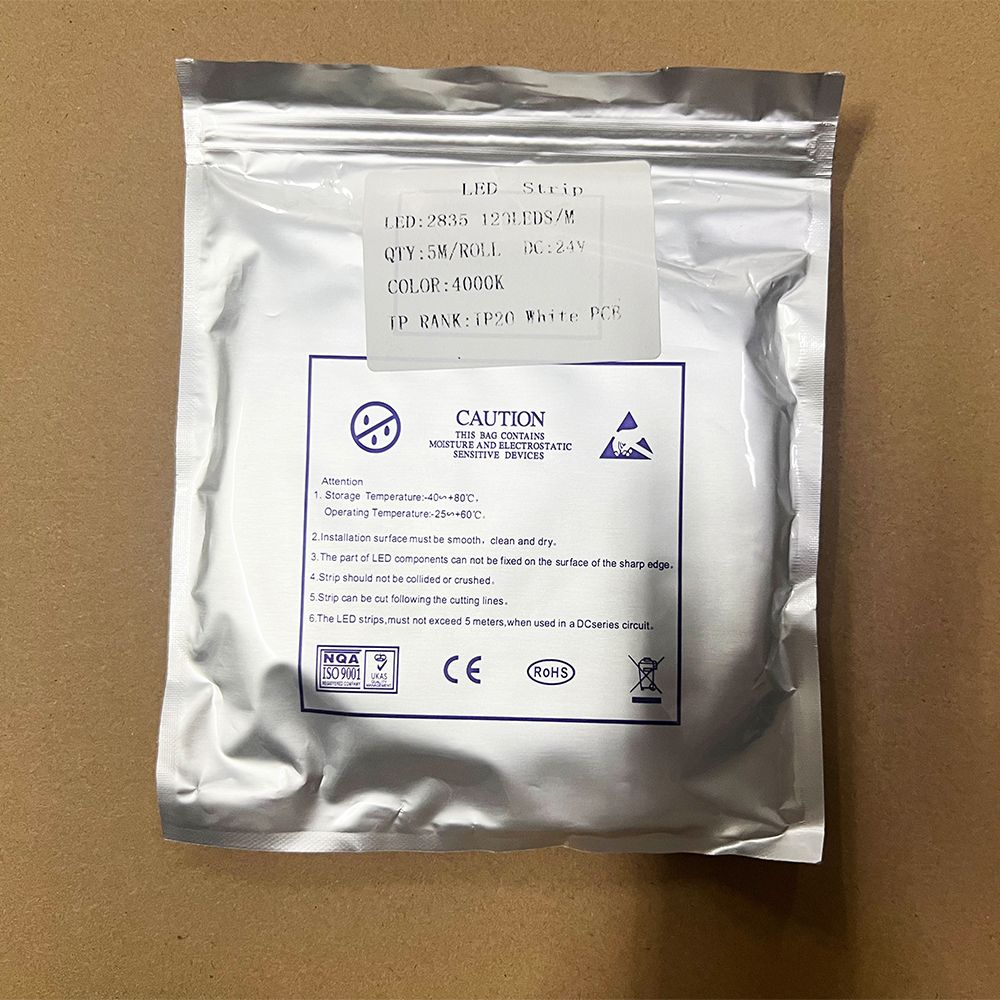

STORAGE CONDITIONS

- LEDs should be stored in environments of ≤86°F and ≤70%RH.

- Moisture-proof packaging is recommended for storing LEDs.

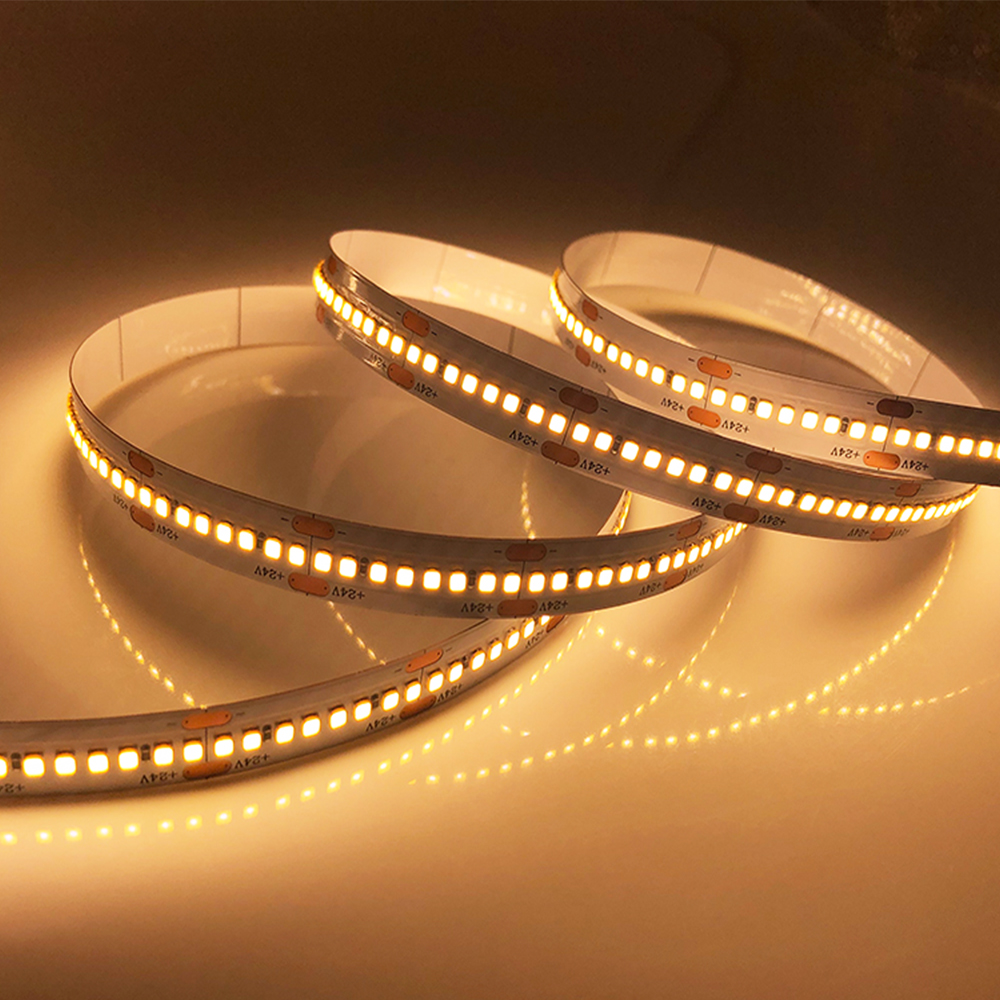

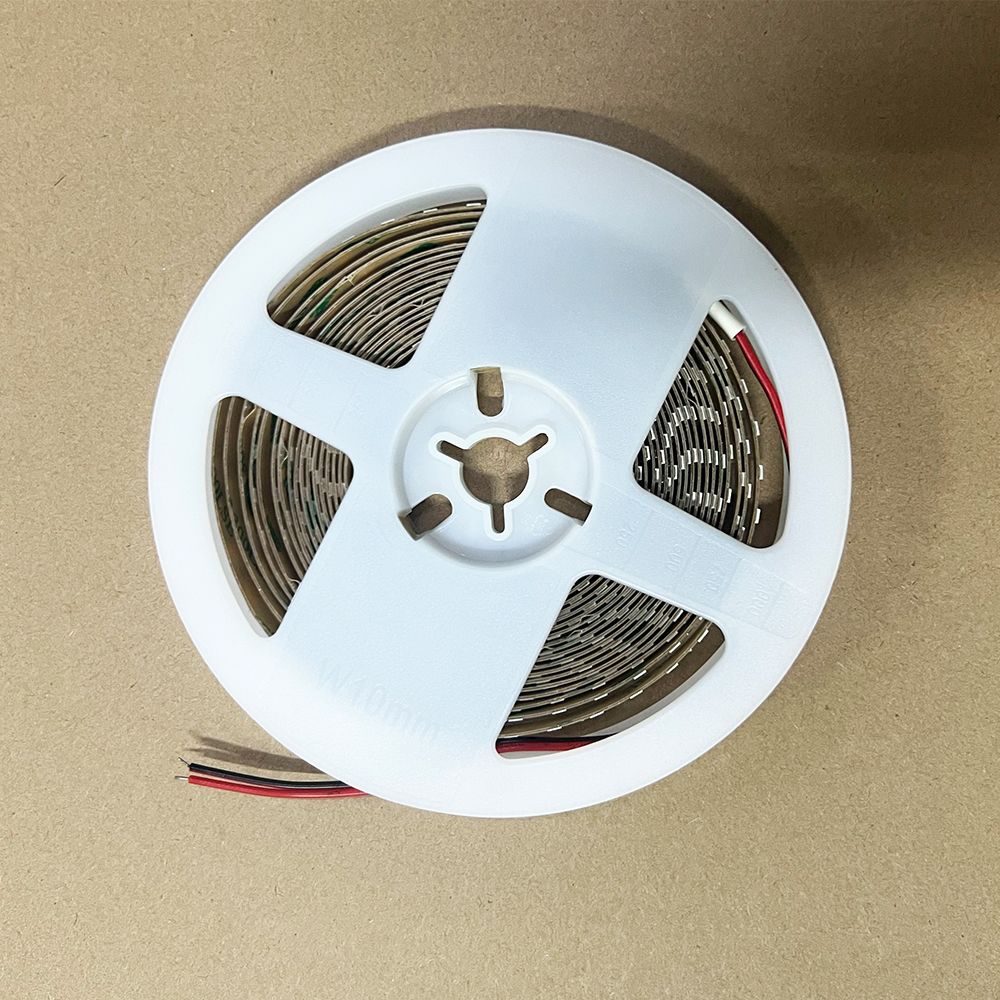

Images of 2018 LED Strip

Here is some of product show in real situation:

Videos of 2018 LED Strip

Custom LED Strip Supplier & Manufacturer

LedDesignsPro is a premier manufacturer and supplier of high-quality LED strips. With years of experience in the industry, we specialize in delivering a wide range of LED strip solutions for residential, commercial, and industrial applications.

Our fully automated production lines ensure the consistency and quality of our products, allowing us to offer reliable, energy-efficient lighting options. We provide OEM and ODM services, customizing LED strips to fit your exact specifications, including LED density, PCB width, color temperature, and waterproof ratings.

We are committed to producing LED strips that meet the highest industry standards. All of our products are CE and RoHS certified, ensuring they are safe and eco-friendly. With competitive pricing, flexible order volumes, and a dedicated support team, LedDesignsPro is your trusted partner for all your single color LED strip needs.

Customizing LED Strip Components:

1. Customizing LED Quantity:

Based on customer requirements, the number of LEDs per meter can be adjusted. Changing the density of LEDs affects the strip's lighting effect, with higher densities providing better linearity. Additionally, adjusting the arrangement of LEDs impacts the brightness and voltage drop across the strip, allowing for tailored lighting performance.

2. Customizing PCB Boards:

LED strips can have customized PCB boards to suit different installation environments. For narrow spaces, thinner strips can be produced, while for higher brightness needs, wider PCBs may be used to enhance heat dissipation. Moreover, double or triple-row LED arrangements can be achieved by expanding the PCB width to deliver the desired lighting effects.

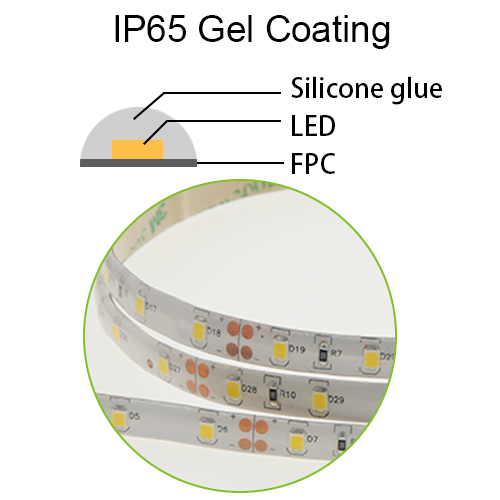

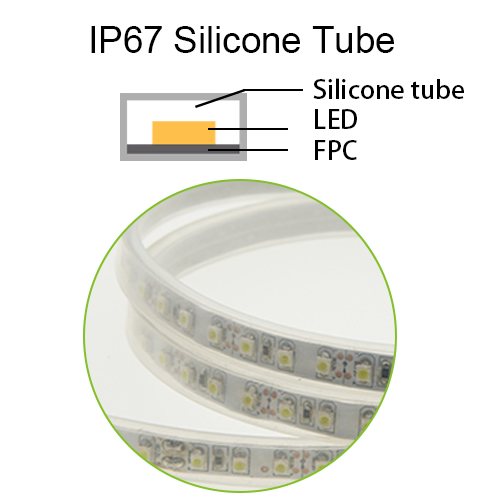

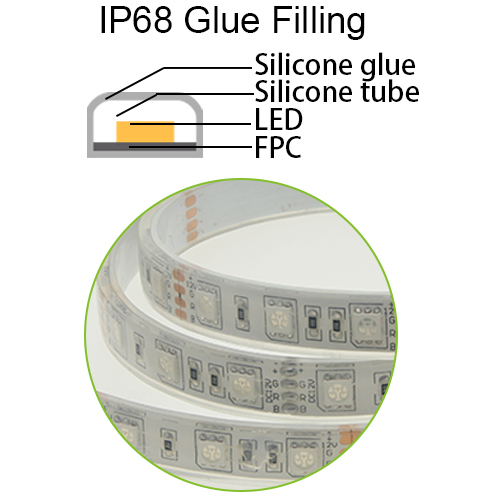

3. Customizing Waterproofing:

Depending on the intended usage environment, various waterproof levels can be applied. For instance, IP20 indicates no waterproofing, IP65 is gel-coated, and IP67 uses tubing or extrusion methods for waterproofing. For outdoor applications like neon LED strips, IP67 is commonly used, and IP68 offers the highest level of waterproofing with considerations for plug and cable sealing to ensure complete water resistance.

This level of customization ensures that clients get the most suitable LED strip solutions for their specific projects, whether for indoor decor or demanding outdoor lighting installations.

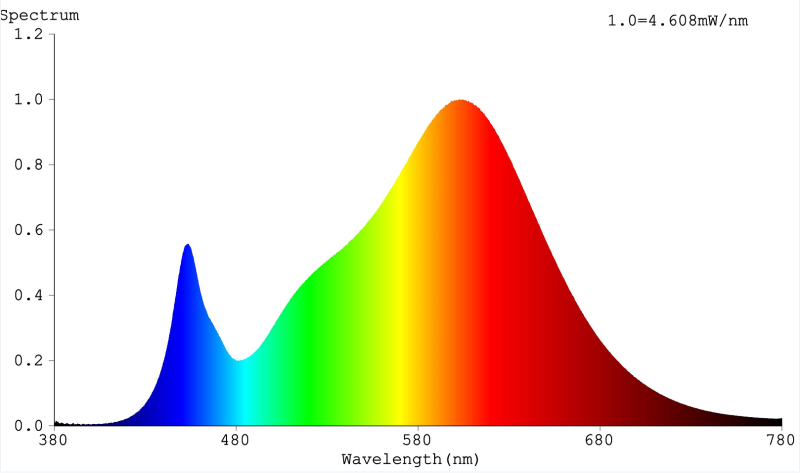

4. Customizing Color Temperature:

We offer standard color temperatures of 3000K, 4000K, 6000K, 8000K, and 10000K. Additionally, we can customize specific color temperatures based on customer requests. In certain environments, strict requirements for color temperature are essential. If customers provide the x and y chromaticity coordinates on the color spectrum chart, we can produce a color that precisely matches their needs.

This level of customization ensures that lighting solutions not only meet aesthetic preferences but also adhere to technical specifications for specialized environments.

5. Custom Color Steps:

Our standard offering for LED strip products is three-step color binning, ensuring consistency in light output. However, if customers require finer precision, we can provide a one-step binning process, which guarantees even tighter control over color consistency.

6. Custom Color Rendering Index (CRI):

Some customers require specific CRI (Color Rendering Index) standards. Achieving a CRI of 90 is relatively straightforward with current LED technology. However, for higher CRI values, like 95, we need to determine if the requirement is for an average CRI or if specific parameters like R9 (which represents red tones) must also be high. A CRI of 95 or higher is typically needed in specialized environments like photography studios. We can fully meet customer demands for CRI, ensuring optimal color accuracy for any application.

7. Custom Packaging:

Single-color LED strips are often used for home and commercial decor, and we provide packaging customization to cater to wholesalers. This includes custom labels, special bags, boxes, and display stands, offering a one-stop service experience for our clients.

Industry Expertise: We bring years of customization experience, having served notable clients such as Ford and Best Buy with OEM and ODM services. Our products adhere to ISO9001, CE, RoHS, and UL standards, ensuring quality and reliability.

For any inquiries, our sales team is available 24/7 to provide comprehensive support.

With our extensive experience in customizing LED strips, we have provided OEM and ODM services to well-known brands like Ford and Best Buy. All our products comply with ISO9001, CE, RoHS, and UL certifications. We are confident in our ability to deliver products that meet your specific needs. If you have any requests, please contact our sales team—they are available 24/7 to offer you a comprehensive purchasing experience.

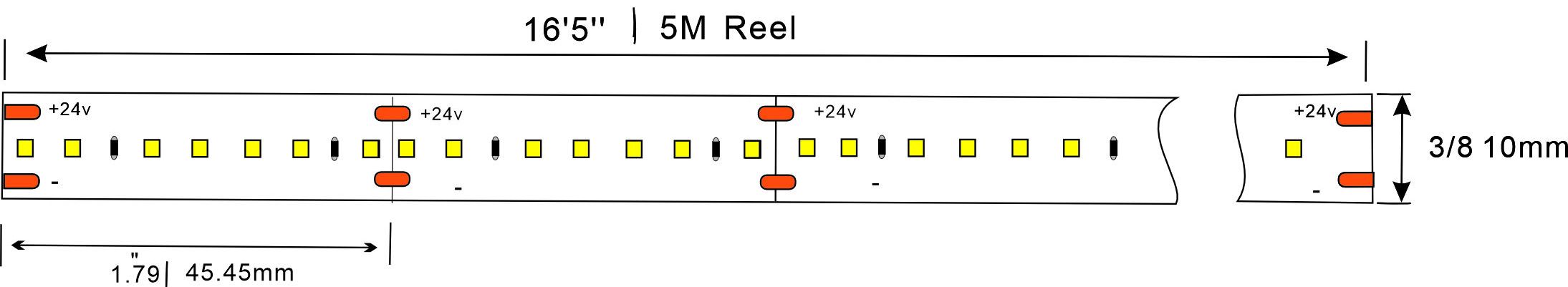

Dimensions

308LEDs/M

320LEDs/M

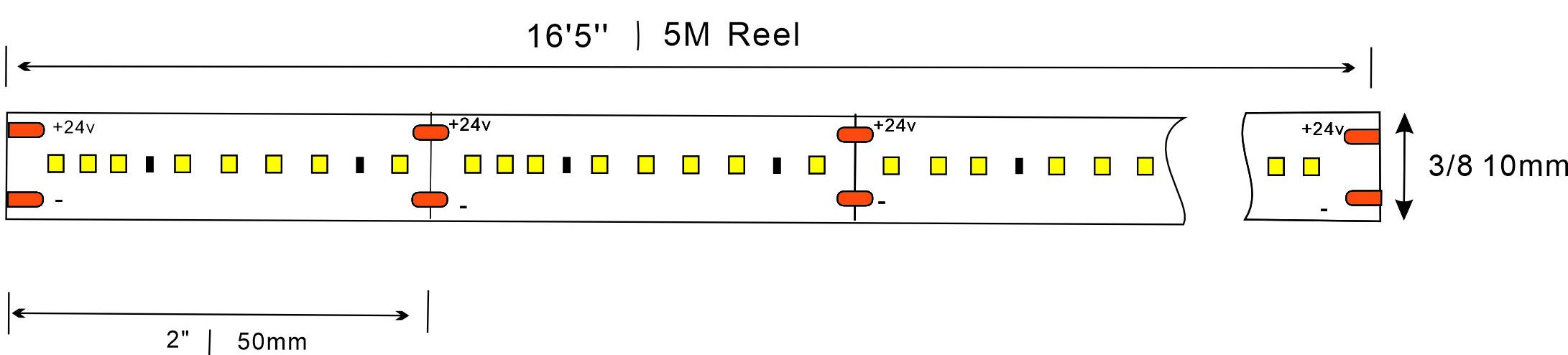

Connect Drawing

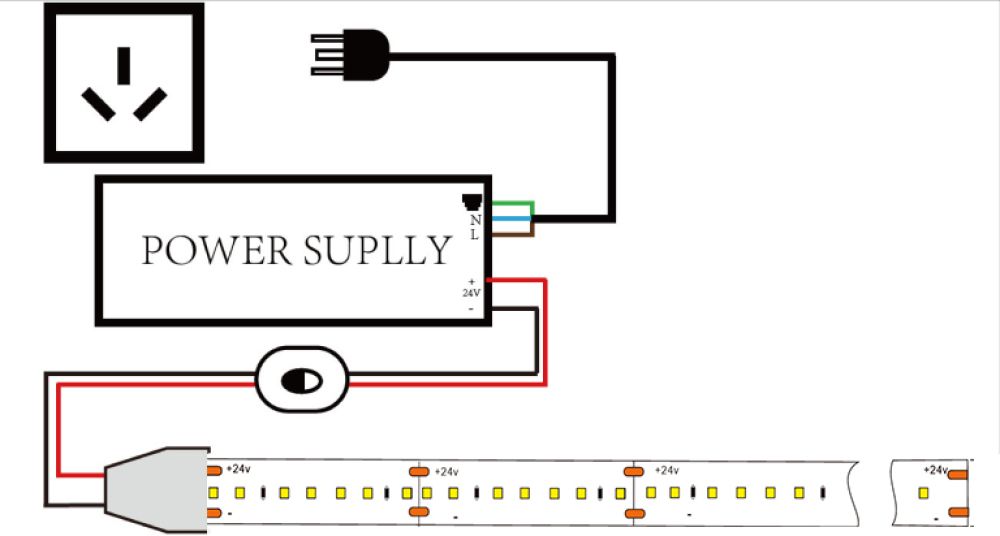

Waterproof Level

Applicable To Dry Environment

Applicable To Wet Environment

Applicable To Water Environment

Applicable To Flooded Environment

2018 LED Strip Application

The 2018 LED strip is widely used across various settings, including indoor lighting (such as in living rooms, bedrooms, and hallways) to enhance the ambiance of a home. It is also applied in commercial spaces to highlight products and increase visual appeal, as well as in landscape lighting to add beauty and security to outdoor gardens and building facades.

Installation

(1) Paste Installation:

This Installation Method is Generally Used for the Waterproof Environment,

And the High-Viscosity 3m Adhesive is Attached to the Back of the Lamp Strip,

Which Can Be Directly Pasted on the Required Solid. The Surface of the Media.

Easy To Use And Easy To Install

Tear Off The Adhesive Tape

Paste To Where You Need To Install

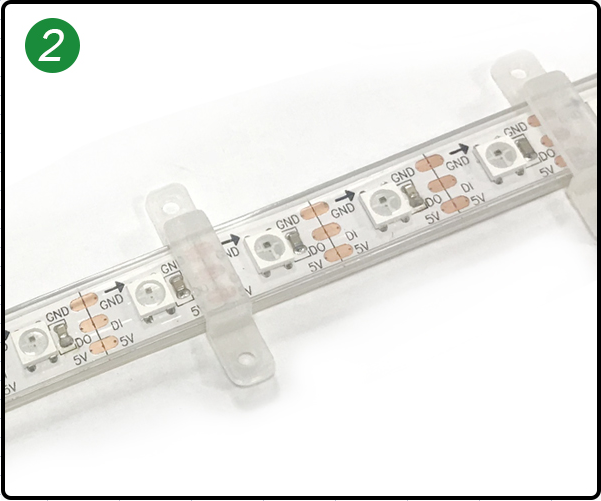

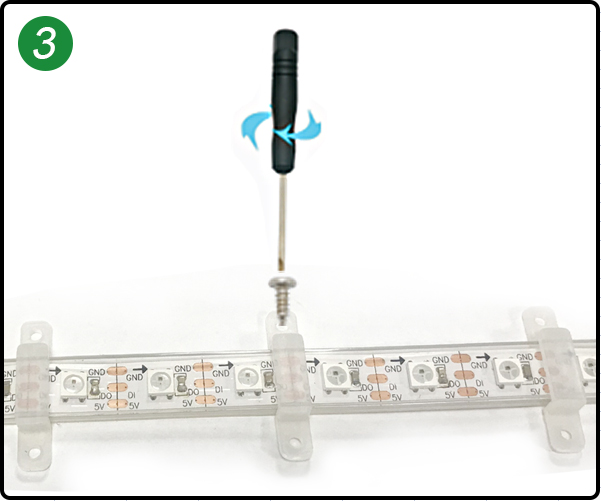

(2) Snap-on Installation:

This Installation Method is Suitable for the Casing Waterproof Product.

The Product is Fixed by the Screw Transparent Buckle to Make the Installation Firmer.

Accessories Clips Screw Screwd Diver

Put The Clips On The Strip

Fixed The Clips

How we guarantee the quality

As a professional LED manufacturer, we ensure that all our LED strips undergo rigorous testing to guarantee their quality and durability. Below are the specific tests, conditions, cycles, criteria, and equipment used to maintain high product standards:

|

Product Reliability Project |

||||

|

Test Item |

Test Conditions |

Duration/Cycle |

Judgment condition |

Use equipment |

|

Thermal Shock |

–40℃ 30min↑↓5sec100℃ 30min |

200cycles |

No cracked glue, no dead light |

Hot and cold shock box |

|

Humidity Heat Storage |

Ta=85℃、RH=85% Rated voltage |

1000hr |

Luminous decay≤10%,no cracked glue, no dead light |

High temperature and humidity box |

|

Life Test |

Ta=25℃ Rated voltage |

1000hr |

Luminous decay≤3%,no cracked glue, no dead light |

Room temperature aging seat |

|

High Humidity Heat Life Test |

60℃ RH=90% Rated voltage |

1000hr |

Luminous decay≤10%,no cracked glue, no dead light |

High temperature and high humidity aging box |

|

Twist Test |

360°/cycle Fixed and twisted at both ends |

300 |

No dead light, no cracked glue |

Distortion test machine |

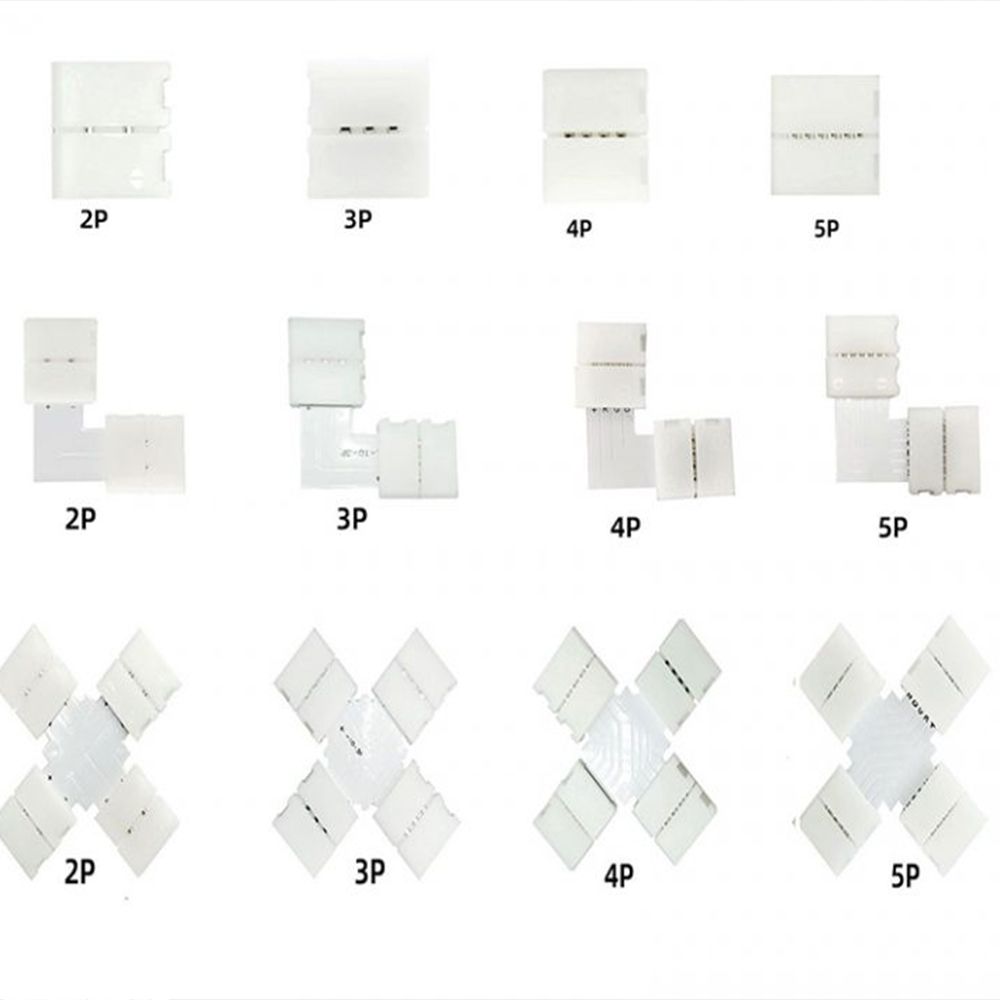

Accessories

Connectors

Aluminum Profiles

Power Supply

V1 Dimmer Controller

Packing

FAQs

Here is the top frequent asked questions. If you are still not very clear, feel free to content our consultant for more details.

We offer FREE SAMPLES for your business.

SMD5050 and SMD2835 refer to LED chip models, indicating different LED sizes. The SMD5050 is square-shaped, measuring 5.0mm x 5.0mm, and contains three chips within it.

The SMD2835, on the other hand, is rectangular, measuring 2.8mm x 3.5mm, with only one chip inside.

SMD (Surface-Mounted Device) is a type of packaging where the LED chip is placed inside the LED unit, which is then surface-mounted on the PCB board.

Whether SMD LEDs are better depends on the comparison product. Compared to through-hole LEDs, SMD LEDs offer several advantages:

they are more compact, have higher luminous efficiency, and provide better heat dissipation.

The 2835 SMD measures 2.8mm x 3.5mm, while the 3528 SMD measures 3.5mm x 2.8mm. Due to its thinner profile, the 2835 is more widely used in various applications.

Inspire Creative Lighting With LedDesignsPro!

Inspire Creative Lighting With LedDesignsPro!

We are here for all your business needs and questions.