The Importance of LED Connectors: Making Connections Easier and Installation Perfect

When installing LED strips, have you ever encountered these situations?

- The strip needs to turn around a corner, but you don’t know how.

- You measured the length correctly, but during installation it turns out to be too short.

- After using it for a while, a section of the strip stops lighting up.

These problems aren’t actually complicated. A small LED connector can easily solve them. With it, installing LED strips becomes more flexible, and extending or repairing them becomes much simpler.

What Is an LED Connector?

An LED connector is a small accessory used to connect LED strips to other strips or to a power supply.Though compact, it serves as a crucial “bridge” in the entire system.

Unlike traditional soldering, using a connector requires no soldering iron or tools — installation can be completed in just a few seconds.

Connectors usually feature a clip-on or pin design, allowing the conductive contacts to press tightly against the copper pads on the strip, forming a stable electrical connection.

✅ Simple: No technical background required; even beginners can install it.

✅ Fast: Takes only a few seconds, saving installation time.

✅ Safe: Avoids burns, short circuits, and other soldering risks.

✅ Neat: Compact design doesn’t affect appearance.

Common Types of LED Connectors

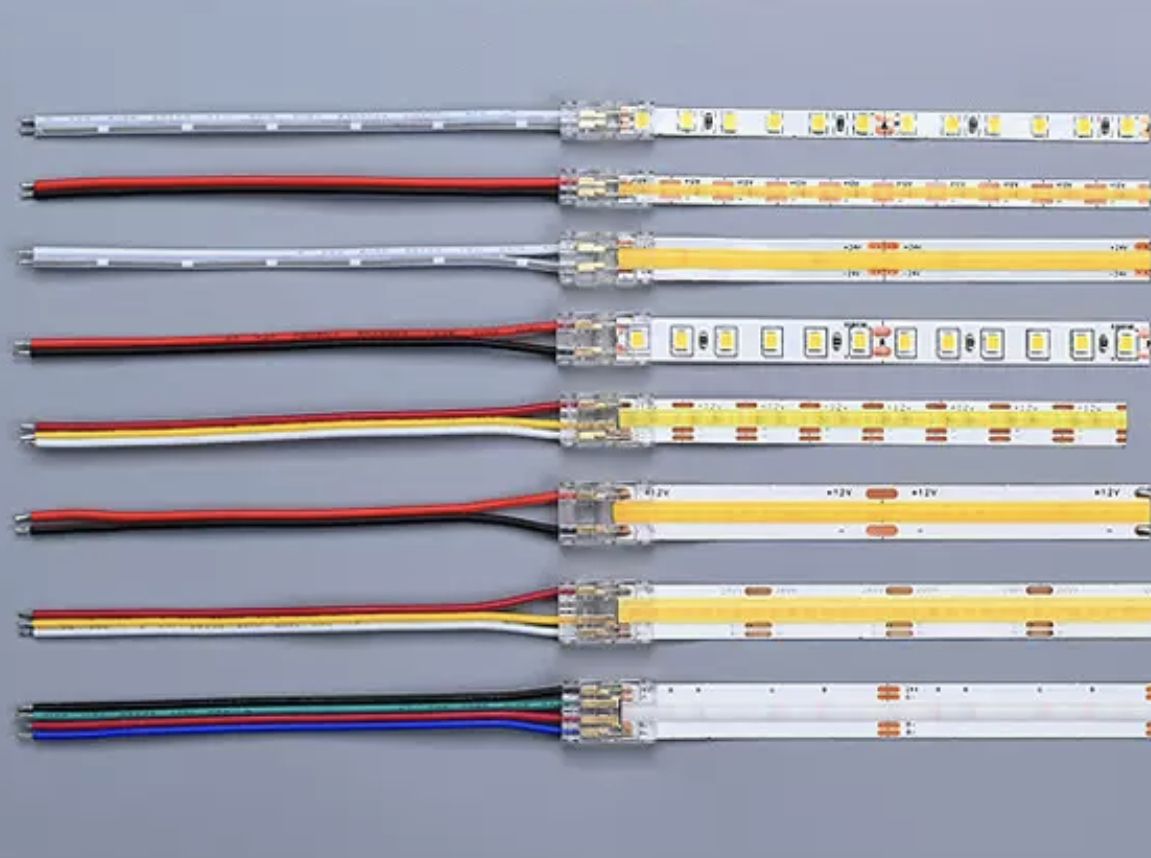

Different types of LED strips correspond to different connector styles. The following are the common categories:

| LED Strip Type | Number of Pins | Strip Width | Common Applications |

| Single-Color Strip | 2-pin | 8mm / 10mm | Cabinets, display cases, corridors |

| CCT Tunable White Strip | 3-pin | 10mm | Bedrooms, offices, shopping malls |

| RGB Strip | 4-pin | 10mm | Entertainment areas, gaming desks, advertising decorations |

| RGBW Strip | 5-pin | 10mm / 12mm | Home decoration, stages, bars |

| RGBCCT Strip | 6-pin | 12mm |

High-end projects, smart control systems |

In addition, based on the usage environment, connectors can be divided into two main categories:IP20 Non-Waterproof Connectors: Suitable for standard indoor LED strips.

IP65 / IP67 Waterproof Connectors: Designed for outdoor or humid environments, such as gardens, around swimming pools, and commercial signage.

IP20 connectors are used with non-waterproof LED strips.

PCB + Cable (with cable)

Middle connector

Connector+cable + Connector

IP67 waterproof connectors are used with IP67 waterproof LED strips.

IP67-Waterproof-Piercing Board-to-Board-Connection

IP67-Waterproof-Piercing Single-End-Cable-Exit

IP67-Waterproof-Piercing Cable-Exit-in-the-Middle

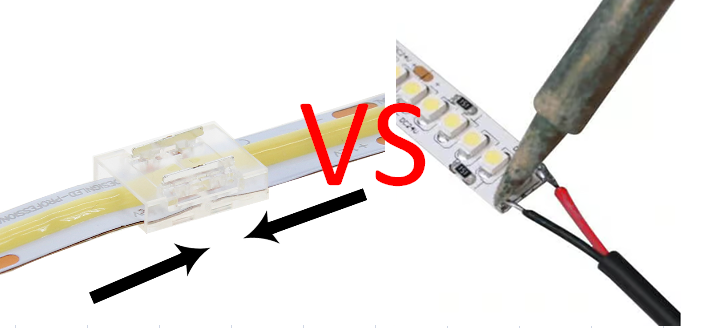

Soldering vs. LED Connectors: Which Is Right for You?

Soldering:

Requires tools such as a soldering iron, solder, and flux, and demands a higher level of skill. If the soldering is not secure or the joint is weak, the LED strip may fail to light up or cause a short circuit.

For non-professionals, soldering is not only cumbersome but also carries safety risks.

LED Connectors:

No tools or electrical expertise required — just snap and connect. Inside the connector, copper contacts clamp onto the LED strip pads, ensuring stable conductivity. When you need to make a corner, extend, branch, or repair the strip, simply plug and unplug — reusable, saving time, effort, and cost.

| Comparison Item | Soldering | LED Connectors |

| Difficulty | High | Low |

| Tools Required | Multiple | None |

| Cost | High | Low |

| Safety | Risk of burns | Safe and worry-free |

| Appearance | Less neat | Compact and tidy |

Application Scenarios for LED Connectors

The flexibility of LED connectors allows them to handle almost any scenario:

- Home Decoration: TV walls, cabinet lighting, ceiling cove strips — easily make corners and extensions.

- Commercial Lighting: Display racks, shop windows, signage strips — quick splicing saves installation time.

- Entertainment Equipment: Gaming consoles, booth tables, KTV venues — enables complex wiring layouts.

- Engineering Projects: Long-distance installations with multiple strip branches — connectors show their advantages.

When a strip is damaged or needs replacement, you no longer have to resolder the entire strip — simply unplug the old strip and insert the new one.

Choosing the Right Connector Is Crucial

Not all LED strips can use the same type of connector.

Before choosing, be sure to check the following:

- Number of Pins: Must match the LED strip type (2-pin, 3-pin, 4-pin, 5-pin, 6-pin).

- PCB Width: Common widths are 8mm, 10mm, and 12mm; different widths are not interchangeable.

- Waterproof Rating: Choose IP20 or waterproof versions according to the environment.

- Connection Type: Consider if you need corners, extensions, or T-shaped branches.

Selecting the right connector not only ensures a secure connection but also prevents issues like poor contact or flickering later on.

Conclusion: Small Accessory, Big Impact

Never underestimate this small LED connector — it not only makes installation more efficient but also makes the entire system more flexible and reliable.

Whether you’re a professional installer or a first-time user, an LED connector lets you easily enjoy a “plug-and-play” experience.

When connections become simple, you can focus more on creativity and design.— This is the true purpose of the LED connector.