- The Complete Guide to LED Aluminum Profiles: Every Step from Selection to Installation

- 1.What is a LED Strip Aluminum Profile?

- 2.Why Choose LED Aluminum Profiles?

- 3.Thick vs. Slim LED Aluminum Profiles: Which Is Better for Your LED Strip?

- 4. Advantages of LEDworker Lighting LED Aluminum Profiles

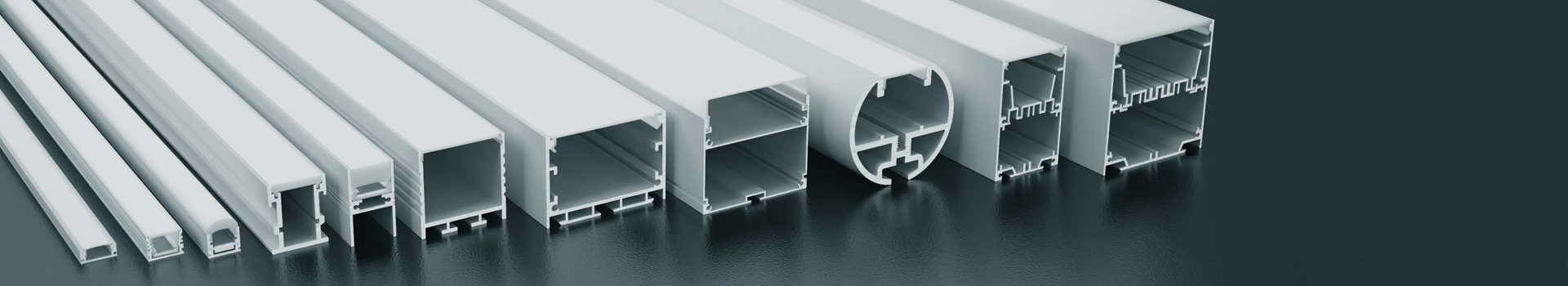

- 5. LED Aluminum Extrusion Types: A Buyer’s Guide for Lighting Projects

- 6.How to choose Aluminum Profile?

- 7.Complete Guide to LED Aluminum Profile Applications | Where to Use LED Channels

- 8.How to Install LED Aluminum Profiles?A Complete Step-by-Step Guide

- 9.FAQ

- REQUEST A QUOTE

The Complete Guide to LED Aluminum Profiles: Every Step from Selection to Installation

1.What is a LED Strip Aluminum Profile?

LED Strip Aluminum Profile — also known as LED Aluminum Profile, LED Strip Channel, LED Strip Diffuser, LED Extrusion Profile, LED Profile Housing, LED Channel System, LED Aluminum Channel, or LED Light Bar Profile — may go by many names, but they all refer to the same essential product: an aluminum channel designed to improve heat dissipation for LED Strip Light.

These profiles not only help extend the lifespan of LED strips by enhancing heat dissipation but also make installation easier and ensure a cleaner, more professional, and aesthetically pleasing lighting effect.

They are the ideal solution for lighting designers, interior designers, cabinet makers, furniture manufacturers, contractors, and builders who demand high-quality, reliable, and visually attractive LED strip installations.

1.1. Excellent Heat Dissipation

LED strips generate heat during operation. Without effective thermal management, the strips may suffer from reduced brightness, color shifts, or even premature failure. High-quality aluminum profiles—especially Ultra-Narrow LED Profiles designed for tight spaces—provide outstanding heat dissipation, ensuring stable and long-lasting LED performance.

1.2. Reliable Protection for LED Strips

Bare LED strips are vulnerable to dust, moisture, oil, and physical damage. Using an aluminum profile with a PC or PMMA diffuser cover protects the LED strip from environmental hazards, enhances product durability, and ensures consistent light output. The Recessed Aluminum Channel series offers seamless installation for hidden and elegant lighting designs.

1.3. Enhanced Light Diffusion and Visual Comfort

LED profiles allow the use of various diffuser covers (clear, frosted, opal) to reduce glare, eliminate LED hotspots, and produce soft, uniform lighting. This feature is essential for modern interior designs requiring smooth and comfortable illumination.

1.4. Wide Range of Installation Options

To meet diverse lighting design needs, LED aluminum profiles are available in multiple series, each tailored for different applications:

✅ Complete LED Profile Product Series:

Ideal for wardrobes, display cabinets, and furniture lighting, ensuring sleek and hidden installations.

Surface-mounted Series

Designed for direct mounting on walls, ceilings, or other surfaces, offering quick and simple setup.

Corner Light Series

Perfect for 90-degree corner installations, providing flexible lighting angles for ceilings and walls.

Laminate & Stair Linear Light Series

Specially developed for shelf undersides and stair steps, combining safety with aesthetic linear lighting.

Three-side Light Series

Provides 270-degree illumination, suitable for showcases and display shelves requiring three-sided lighting effects.

Clapboard Series

Ideal for bookcases and shelf lighting, delivering soft and focused light without harsh spots.

Recessed Series

Designed for flush installation into walls, ceilings, or furniture, ensuring a clean and modern look.

Trimless Recessed Series

Offers edge-free designs for seamless integration into architectural spaces, perfect for high-end interior lighting projects.

Indirect Lighting Series

Produces soft reflected light for ambient illumination, enhancing the atmosphere without direct glare.

Skirting Light Series

Used along skirting boards to create functional and decorative lighting effects near the floor.

Stairs and Inground Light Series

Suitable for outdoor pavements or indoor stair guidance lighting, designed with waterproof and dustproof features.

Magnetic Track Light & Anti-glare Series

Features magnetic installation with anti-glare designs, popular in commercial and retail lighting applications.

Recessed Series

Offers deeply embedded installation for modern, minimalist lighting solutions.

Suspended Series

Perfect for hanging applications in offices, meeting rooms, and dining areas, providing wide and even light distribution.

Tri-proof Light Series

Engineered for waterproof, dustproof, and corrosion-resistant performance in harsh environments like factories and warehouses.

DIY Customized Bending Style Series

Supports creative, custom-bent profiles for artistic and special-shaped lighting projects.

1.5.Suitable for Various Lighting Projects

Whether it’s for residential kitchens, stairways, office ceilings, hotel lobbies, retail displays, or outdoor pathways, LED aluminum profiles offer tailored solutions that meet the functional and decorative needs of different spaces.

Choosing the right LED Aluminum Profile—especially from our Ultra-Narrow LED Profile or Recessed Aluminum Channel ranges—ensures superior light quality, product durability, safety, and overall design elegance. A complete selection of 16 specialized series enables architects, designers, and contractors to realize their unique lighting visions with confidence.

LED aluminum profiles, also known as LED diffuser channels or LED aluminum extrusions, are essential accessories for LED strip lights. They comprise an aluminum base, cover, clips, end caps, and screws. Their primary purpose is to protect LED strips while enhancing their appearance. Profiles diffuse the light, creating a softer, more uniform glow that adds warmth and a modern touch to spaces. Additionally, the aluminum material offers excellent heat dissipation, extending the lifespan of LED strips and preventing overheating.

2.Why Choose LED Aluminum Profiles?

In modern interior design and lighting projects, LED strip lights have become a popular choice thanks to their flexibility, energy efficiency, and versatility. However, many overlook an essential accessory that can greatly impact both performance and aesthetics — the LED Aluminum Profile (also known as LED Strip Channel, LED Extrusion Profile, or LED Strip Diffuser). Why are more designers, furniture makers, and contractors choosing to use LED aluminum profiles? Let’s explore the key reasons.

2.1. Extend the Lifespan of LED Strips

LED strips generate heat during operation. Without proper heat dissipation, this heat can reduce brightness over time and shorten the lifespan of the LEDs. LED aluminum profiles are made from high-quality aluminum with excellent thermal conductivity, helping to transfer heat away from the LED strip efficiently. This prolongs the life of the LED strip and ensures reliable, long-term performance — especially important in commercial spaces, display cabinets, and kitchen applications where the lights are used continuously.

2.2. Improve Light Quality and Visual Appearance

Uneven lighting or visible LED dots can negatively affect the overall look of a space. LED aluminum profiles paired with diffusers (made from PC or PMMA) help create soft, uniform lighting by eliminating harsh spots and shadows. Whether used for cabinet lighting, stair illumination, accent walls, or backlit mirrors, LED profiles deliver a smooth, professional light output that enhances the atmosphere.

2.3. Make Installation Easier and More Flexible

LED aluminum channels are available in various designs — surface-mounted, recessed, corner, stair-specific, skirting board types, and more — to meet the needs of different applications. Whether you want to conceal the light source or highlight a linear light effect, aluminum profiles provide versatile solutions. They also come with complete accessories like end caps, mounting clips, and connectors, making installation quick, simple, and time-saving.

2.4. Enhance the Overall Design Quality

Compared to exposed LED strips, aluminum profiles give a finished, high-end appearance to any installation. Aluminum’s strength also protects the LED strips from damage, dust, and moisture. With a sleek and modern design, these profiles blend seamlessly into various interior styles — from minimalism and industrial to luxury and classic. This allows for a more cohesive and professional result in both residential and commercial spaces.

2.5. Meet Diverse Application Needs

Every space has different lighting requirements. LED aluminum profiles offer flexible solutions for a wide range of uses — under cabinet lighting, display shelving, stair lighting, skirting board illumination, backlit mirrors, cove lighting, and more. Customization is also possible, giving designers and manufacturers the freedom to turn their ideas into reality.

LED aluminum profiles are more than just accessories for LED strips — they are an essential part of creating high-quality lighting solutions. Whether you are a lighting designer, interior designer, cabinet maker, furniture manufacturer, contractor, or builder, choosing the right aluminum profile ensures your project stands out in terms of durability, performance, and visual appeal.

Looking for reliable, customizable LED aluminum profiles? Contact us today to find the perfect solution for your project.

3.Thick vs. Slim LED Aluminum Profiles: Which Is Better for Your LED Strip?

When it comes to LED strip lighting projects, the LED aluminum profile (also known as LED channel or LED extrusion) is more than just an accessory — it plays a vital role in heat dissipation, light diffusion, ease of installation, and overall appearance.

A common question among lighting designers, contractors, and cabinet makers is: Should I choose a thick or slim LED aluminum profile? Which one suits my LED strip lighting needs best?

Let’s explore the key differences to help you make an informed decision.

3.1. Heat Dissipation & Structural Stability

One of the primary purposes of an aluminum profile is to dissipate heat from the LED strip, protecting the LEDs and extending their lifespan. The profile’s thickness directly affects its performance in this area.

(1) Thick Aluminum Profile

These profiles typically range in thickness from 1.0mm to 3.0mm, offering a robust and durable structure. The extra material enhances heat dissipation, ensuring better protection for the LED chips. This makes thick profiles ideal for high-power LED strips rated at 30W/m or above.

In addition to superior heat management, the increased thickness also provides greater stability and strength, ensuring a more reliable and secure installation, especially important for commercial, industrial, or large-scale lighting applications.

(2) Slim Aluminum Profile

Slim profiles have a thickness of around 0.5mm to 1.0mm and are designed to be lightweight and compact — perfect for installations where space is limited.

While they offer basic heat dissipation and physical protection, their sleek design allows for smaller, lighter, and more portable lighting setups. These profiles are best suited for low-power LED strips under 10W/m, commonly used in under-cabinet lighting, mirror backlighting, and decorative lighting projects where flexibility and aesthetic appeal are prioritized.

3.2. Light Output & Visual Effect

Thick aluminum profiles often feature deeper channels and high-quality diffusers that eliminate hot spots and visible LED dots. This results in smooth, uniform lighting — ideal for areas where perfect light distribution is essential, such as offices, hotel lobbies, and retail displays.

Slim aluminum profiles, with their shallow depth, position the LED strip closer to the diffuser cover, which may produce some spotting. However, they excel in applications where compact design and minimal visual impact are more important than perfectly even light distribution.

3.3. Installation Flexibility & Space Requirements

Slim profiles are the preferred choice for tight spaces — inside cabinets, under shelves, behind mirrors, or even integrated into gaming machines and camera lighting systems.

Thick profiles require more space but provide a sturdier solution for demanding installations like stair lighting, skirting board illumination, or large hidden ceiling light strips where strength and durability are priorities.

3.4. Cost & Budget Considerations

Thick profiles, due to the higher material usage, generally cost more than slim ones. However, they offer better long-term value for high-performance or heavy-use projects by reducing maintenance needs.

Slim profiles are more cost-effective for budget-sensitive projects or short-term applications, such as temporary displays or residential decorative lighting.

Summary: Which One Should You Choose?

|

Project Requirement |

Recommended Profile |

|

Superior light diffusion, dot-free appearance |

Thick Profile |

|

Minimalist design, ultra-slim aesthetic |

Slim Profile |

|

High durability, long lifespan projects |

Thick Profile |

|

Budget-conscious or temporary use |

Slim Profile |

Expert Tip

When choosing between thick and slim aluminum profiles, always consider your LED strip’s power rating, application scenario, available installation space, and budget.

Still unsure? Contact our team today — we can recommend the perfect aluminum profile solution tailored to your specific project needs.

4. Advantages of LEDworker Lighting LED Aluminum Profiles

In the field of LED lighting, LED aluminum profiles (also known as LED channels or LED extrusions) are essential components that directly impact the heat dissipation, lifespan, ease of installation, and final visual effect of LED strip lights. As a professional supplier of LED aluminum profiles, LEDworker Lighting is committed to providing high-quality, cost-effective solutions to customers worldwide. But what makes LEDworker products stand out from the competition?

About LEDworker Lighting

Shenzhen LEDworker Lighting Co., Ltd., founded in 2012 and based in Shenzhen, China, is a leading supplier of LED aluminum profiles. Equipped with advanced manufacturing facilities and strong R&D capabilities, we offer a full range of LED aluminum profile products and accessories to customers in over 200 countries worldwide.

We provide various types of LED aluminum profiles, PC/PMMA covers, end caps, mounting clips, and other related accessories that are widely applied in different industries. With our extensive experience, we also offer personalized recommendations for matching LED strips and profiles to meet the specific requirements of our clients.

4.1. Advanced Aluminum Material for Superior Quality

At LEDworker Lighting, we insist on using aviation-grade AL6063-T5 aluminum alloy as the raw material. This ensures that our profiles feature excellent corrosion resistance, thermal conductivity, oxidation resistance, wear resistance, plasticity, and weldability — making them durable and easy for post-processing or customization.

| Category | Property | Value |

| Mechanical Properties | Tensile Strength | Approx. 175 Rm/MPa |

| Brinell Hardness | Approx. 65 HBW | |

| Processing Standards | Compliance | GB/T 14846-2014 surface treatment standards |

| Surface Finishes Available | Anodizing (Silver, Black, etc.), Powder Coating | |

| Chemical Composition | Aluminum | 98.27% |

| Silicon | 0.40% | |

| Iron | 0.20% | |

| Copper | 0.05% | |

| Manganese | 0.05% | |

| Magnesium | 0.70% | |

| Chromium | 0.03% | |

| Zinc | 0.05% | |

| Titanium | 0.10% | |

| Others | 0.15% | |

| Quality & Supply | Quality Guarantees | Multiple Quality Guarantees |

| Stable Material Supply | Guaranteed Supply Stability | |

| Standard Compliance & Reference | Data Reference | Follows GB/T 3190-2020 standards |

These high-grade materials ensure that our profiles are not only aesthetically pleasing but also highly durable, resistant to deformation, and efficient in heat dissipation — especially ideal for high-standard lighting projects.

4.2. Premium Raw Materials for Outstanding Performance

To further guarantee the quality of our products, LEDworker Lighting selects high-grade PC raw materials imported from COVESTRO Germany. These covers feature excellent light transmittance, smooth matte surface, superior light diffusion, minimal light loss, and exceptional resistance to cracking, bending, wear, and heat — resulting in outstanding durability and optical performance.

4.3. Frosted Acrylic (PMMA) Options for Enhanced Visual Effects

To meet the diverse needs of different lighting projects, LEDworker offers frosted acrylic (PMMA) diffuser covers, widely used in various LED lighting systems. This material provides excellent chemical stability and weather resistance, ensuring long-lasting performance without yellowing, cracking, or deformation — even under prolonged use.

In addition to its durability, the frosted acrylic cover delivers a soft, uniform, and comfortable light diffusion, effectively eliminating visible LED dots and improving the overall visual appeal of the lighting fixture. This makes it ideal for applications where premium light quality and aesthetics are essential, such as decorative, ambient, and architectural lighting.

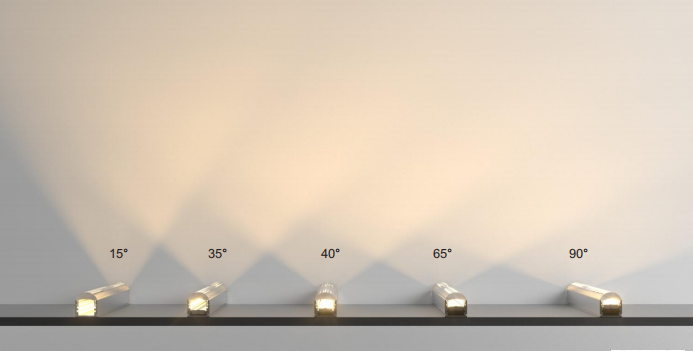

Furthermore, our acrylic diffusers can be specially designed with built-in lens effects to modify the beam angle of the light output. This feature allows the creation of customized light distribution solutions — whether widening or focusing the light beam — to suit specific project requirements. Such functionality is particularly useful for applications like display cabinets, mirror lights, and under-cabinet lighting, where precise light control is needed to enhance visual performance.

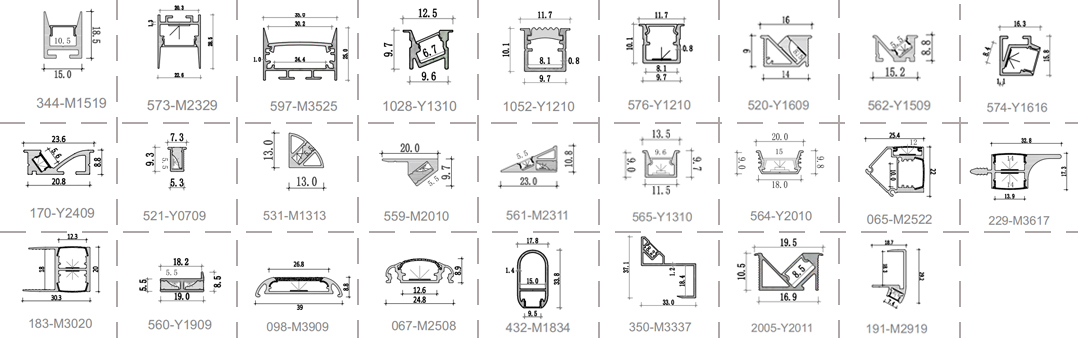

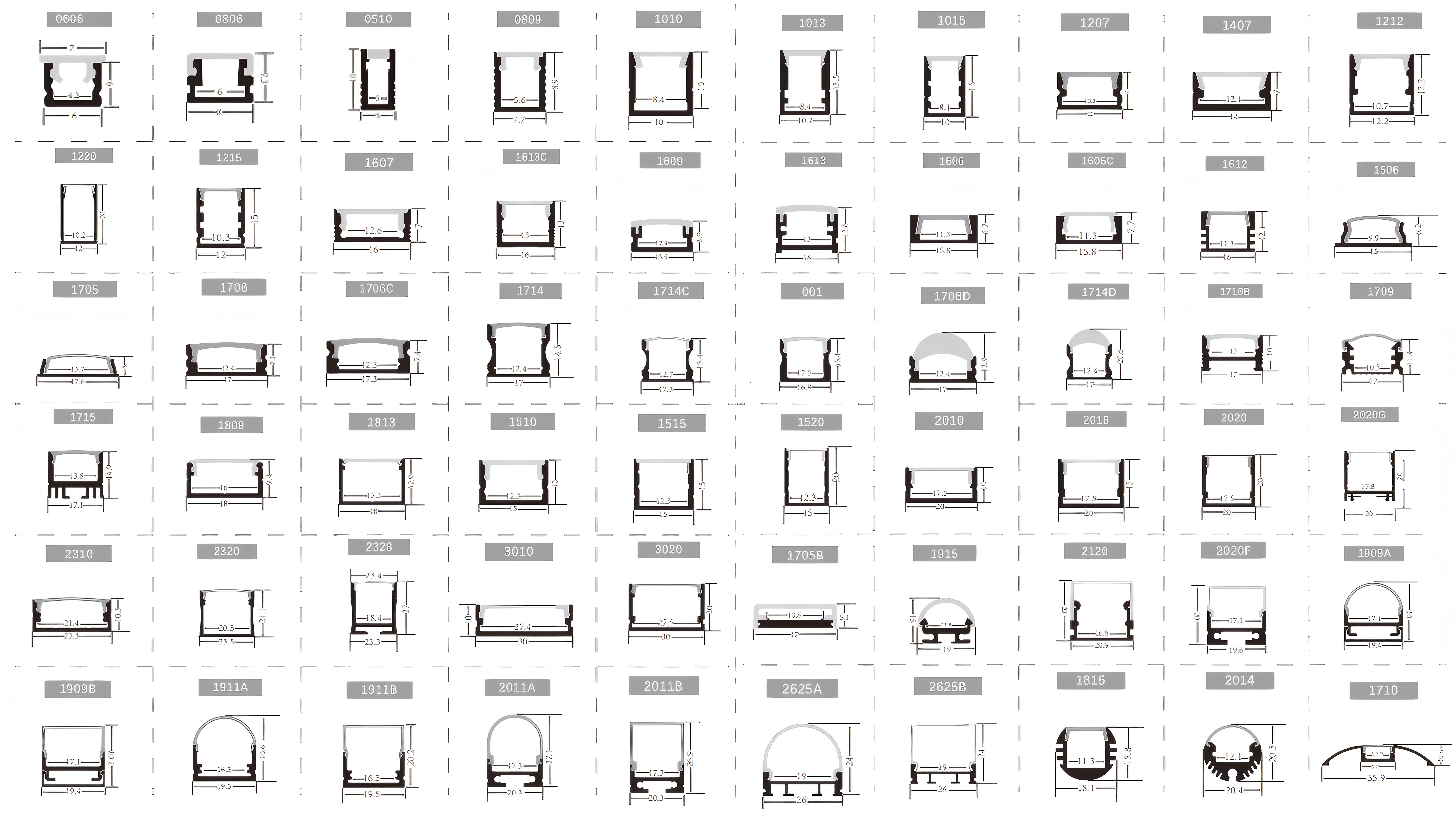

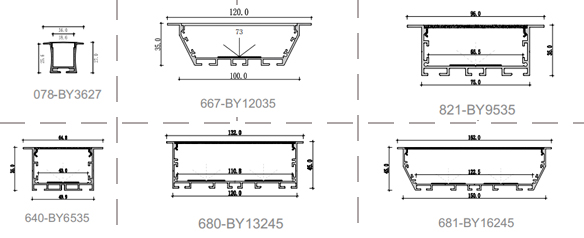

4.4. Complete Range of Specifications to Meet All Needs

LEDworker Lighting offers a comprehensive range of profiles including surface-mounted, recessed, corner, skirting, stair, mirror backlight, ultra-slim, ultra-wide, and large-size customized profiles, fitting various scenarios and design needs. Whether for home interiors, commercial spaces, showcases, or outdoor waterproof applications, we have the ideal solution.

4.5. Fine Appearance and Superior Texture

All LEDworker profiles feature delicate anodized finishes with a smooth, scratch-resistant, and corrosion-proof surface — far superior to standard market products. Combined with high-transparency diffusers, they eliminate LED hotspots and produce a soft, uniform glow, elevating the space’s overall visual appeal — perfectly compatible with modern, industrial, or luxurious styles.

4.6. Flexible Customization and Professional Service

For special project needs, LEDworker offers custom length, color, and structure design services, meeting the creative and functional demands of lighting designers, contractors, and furniture manufacturers. Our engineering team can work directly with customers’ design teams, ensuring fast response and efficient project delivery.

4.7. Complete Accessories and Easy Installation

LEDworker Lighting provides a full set of installation accessories such as clips, end caps, connectors, waterproof joints, etc., ensuring safe, quick, and firm installation. Some models support tool-free clip installation, greatly improving installation efficiency and reducing labor costs — ideal for large-scale engineering projects.

4.8. Strict Quality Control and Reliable Assurance

Every aluminum profile undergoes strict dimensional checks, strength tests, and surface inspections to ensure compliance with international standards. LEDworker promises strict quality control from material selection to final delivery, winning long-term customer trust.

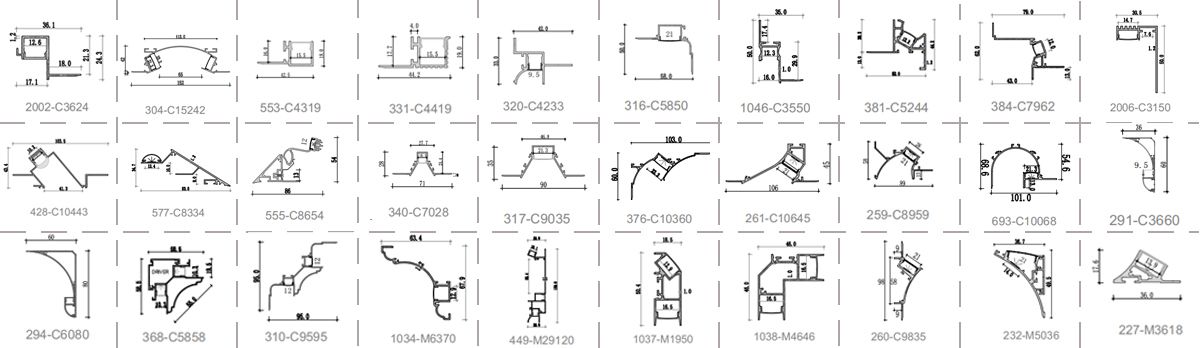

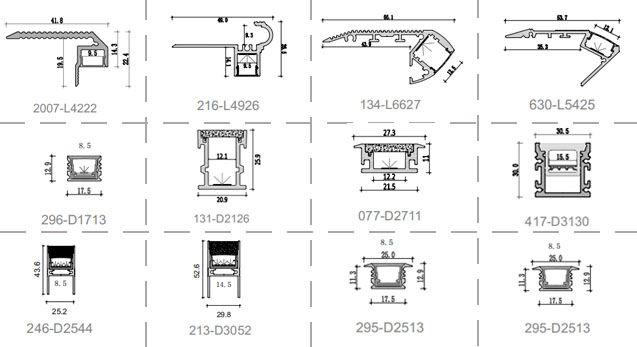

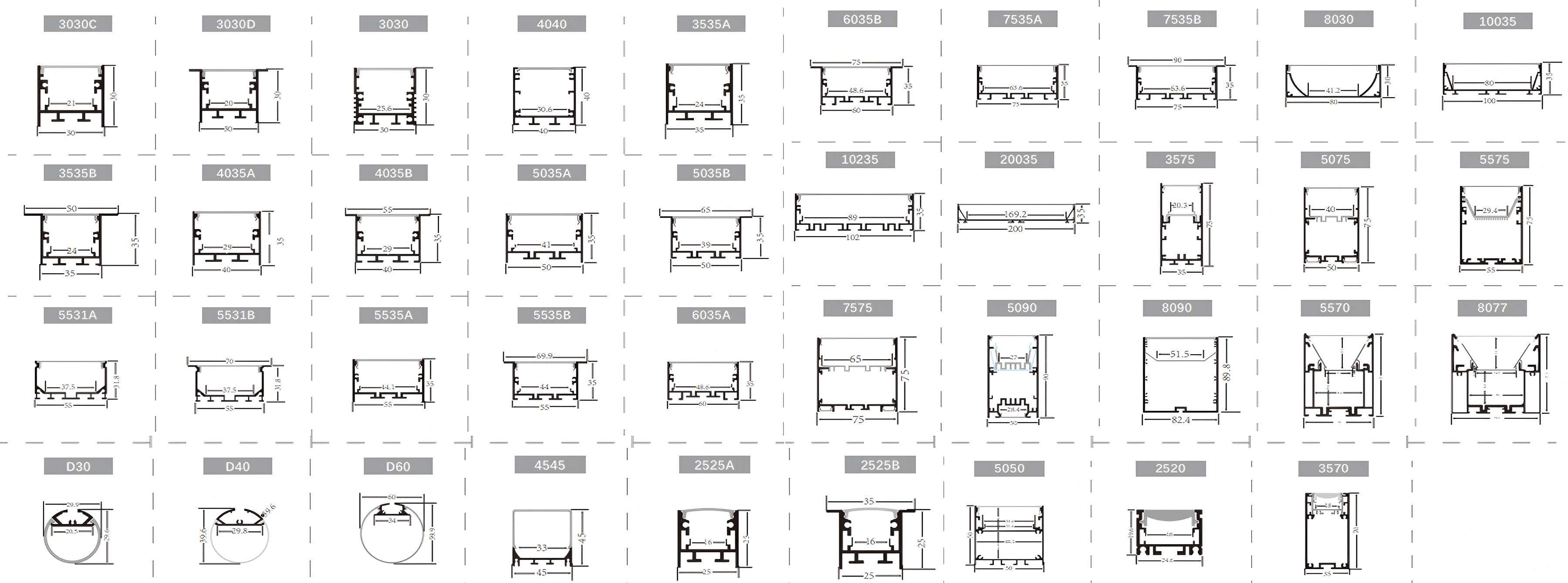

5. LED Aluminum Extrusion Types: A Buyer’s Guide for Lighting Projects

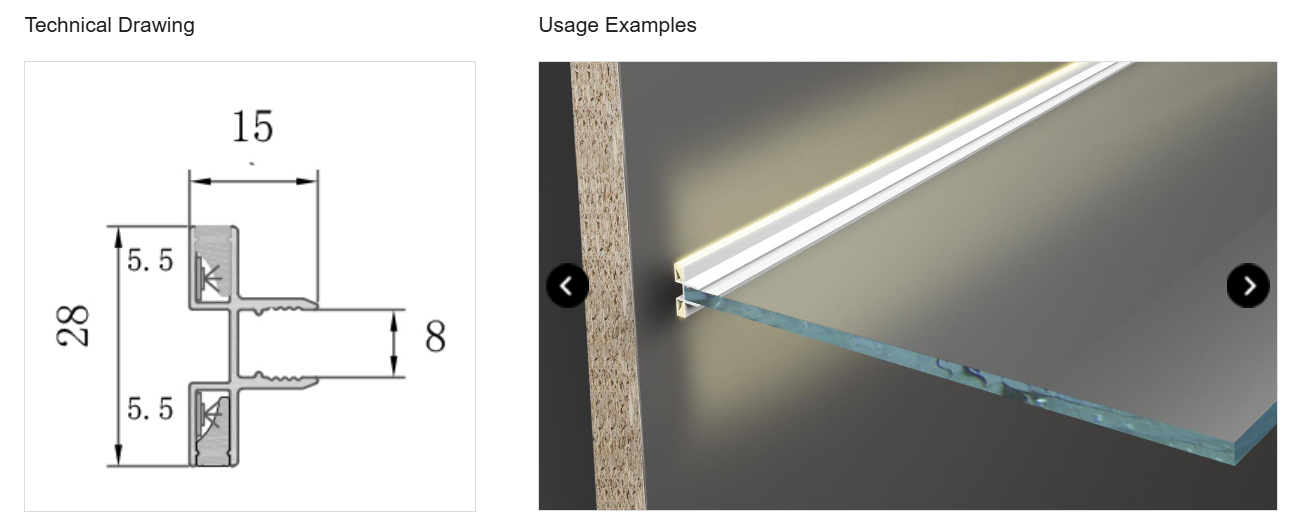

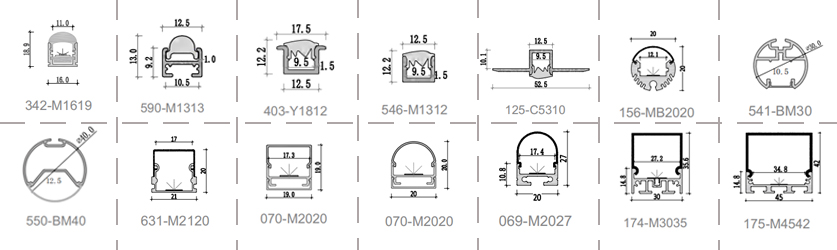

5.1,Cabinet & Furniture Series

(LED Profile for Cabinet Lighting / Aluminum Channel for Furniture)

Applications: Kitchen cabinets, wardrobes, drawers, display cases, furniture edges.

Ideal for: Cabinet makers, furniture designers, home improvement brands.

Advantages: Compact design for easy embedded installation; excellent heat dissipation extends LED strip lifespan; enhances internal cabinet illumination and space aesthetics.

Best Choice: Slim or ultra-thin LED aluminum profiles with high-transparency PC covers; ideal for limited spaces.

5.2, Surface-Mounted Series

(LED Surface-Mounted Aluminum Profile / LED Strip Housing Surface Mount)

Applications: Residential lighting, commercial areas, offices, conference rooms, wall or ceiling mounting.

Ideal for: Home renovators, lighting installers, DIY hobbyists.

Advantages: No slotting required; easy installation on any flat surface; DIY customizable assembly; high flexibility.

Best Choice: Standard or wide surface-mounted LED profiles; thickness depends on LED strip wattage and setup needs.

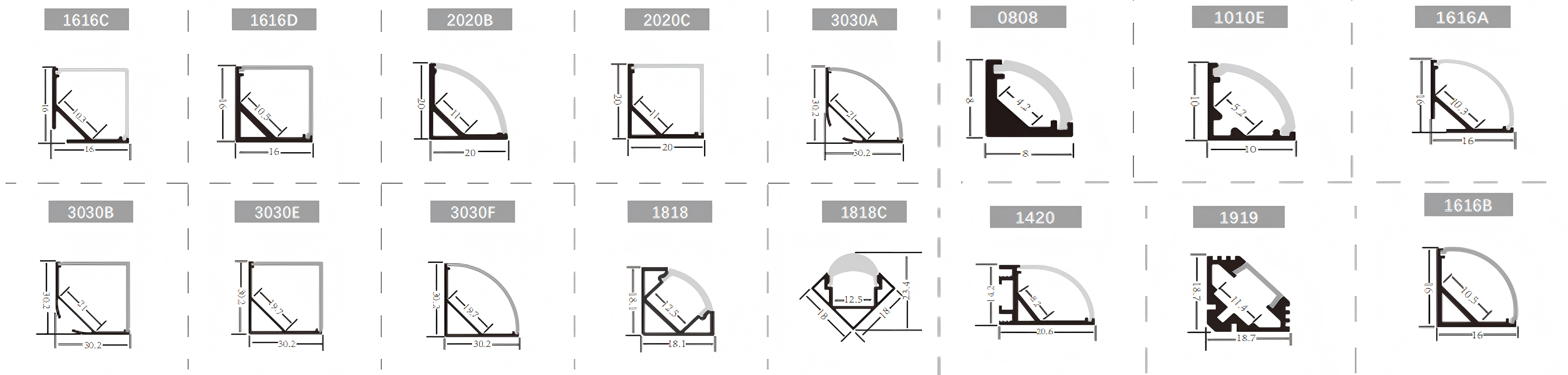

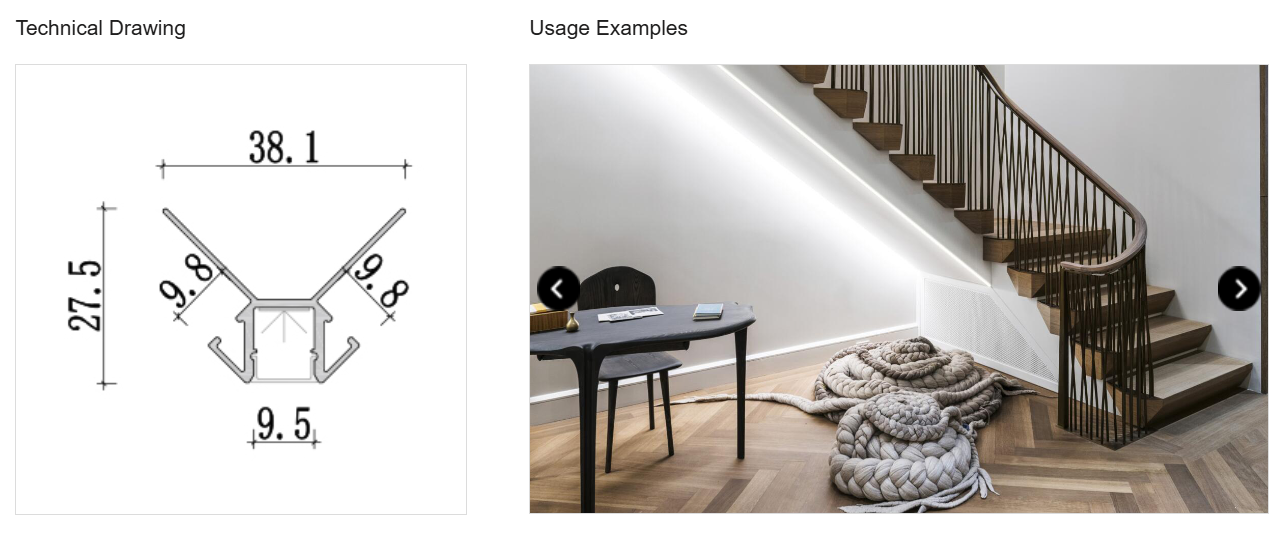

5.3,Corner Light Series

(LED Corner Aluminum Profile / 90 Degree LED Channel)

Applications: Wall corners, ceiling junctions, corner cabinets, L-shaped spaces.

Ideal for: Interior decorators, shopfitting companies, custom display makers.

Advantages: Designed for 90° corners; even light distribution; improves corner illumination.

Best Choice: Inner or outer corner LED aluminum profiles based on actual installation.

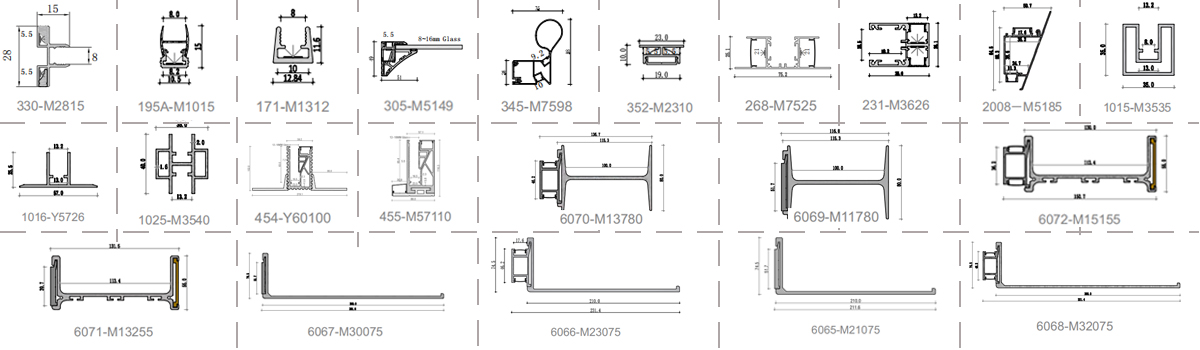

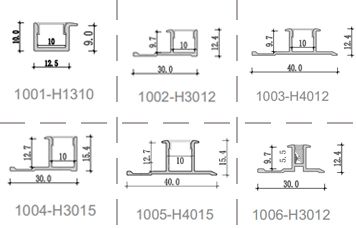

5.4,Laminate & Stair Linear Light Series

(LED Stair Profile / Step Lighting Aluminum Channel)

Applications: Shelves, cabinets, stairs, display racks.

Ideal for: Furniture makers, staircase installers, shop display designers.

Advantages: Gentle downward lighting improves visibility and stair safety; decorative and functional.

Best Choice: Side or downward-emitting stair LED profiles; anti-slip designs for stairs.

5.5,Three-Side Light Series

(Three-Side LED Diffuser / Multi-Directional LED Profile)

Applications: Display cabinets, showcases, glass counters, light boxes.

Ideal for: Retail display makers, exhibition contractors, store renovators.

Advantages: 3-way lighting ensures bright, shadow-free illumination; enhances product appeal.

Best Choice: High-diffusion PC covers for soft, even light.

5.6,Clapboard Series

(Partition LED Profile / Divider Aluminum Channel)

Applications: Bookshelves, partitions, cabinet walls.

Ideal for: Furniture brands, office partition suppliers.

Advantages: Space-saving embedded design; makes multi-layer furniture stylish and functional.

Best Choice: Ultra-narrow or hidden LED profiles for slim spaces.

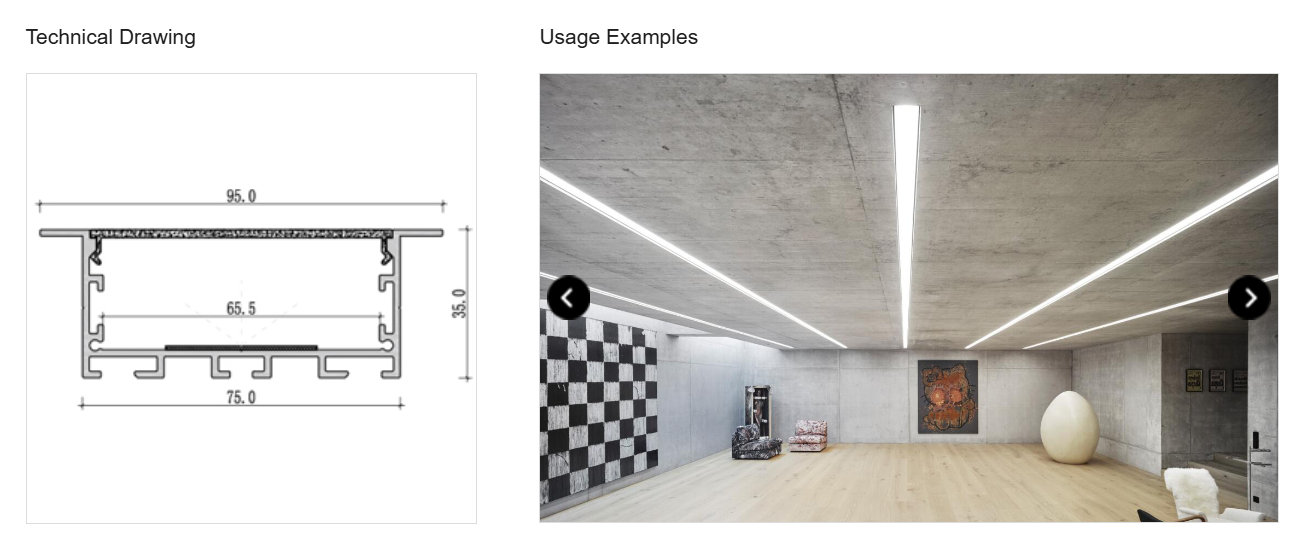

5.7,Recessed Series

(LED Recessed Aluminum Profile / Flush Mount LED Channel)

Applications: Ceilings, walls, panels.

Ideal for: Luxury home builders, modern interior designers.

Advantages: Smooth flush mounting; perfect for clean, hidden lighting styles.

Best Choice: Recessed profiles with light-blocking edges for decoration and illumination.

5.8,Trimless Recessed Series

(Trimless LED Profile / Frameless LED Channel)

Applications: Villas, hotels, premium offices.

Ideal for: High-end architects, luxury interior contractors.

Advantages: Seamless and elegant; fully flush with the surface.

Best Choice: Large trimless profiles for wide and uniform light.

5.9,Indirect Lighting Series

(LED Cove Lighting Profile / Indirect Light Channel)

Applications: Cove ceilings, wall edges, indirect light features.

Ideal for: Decor specialists, creative lighting installers.

Advantages: Soft, ambient light without glare; adds texture and mood.

Best Choice: U-shaped or C-shaped reflective profiles for smooth indirect effects.

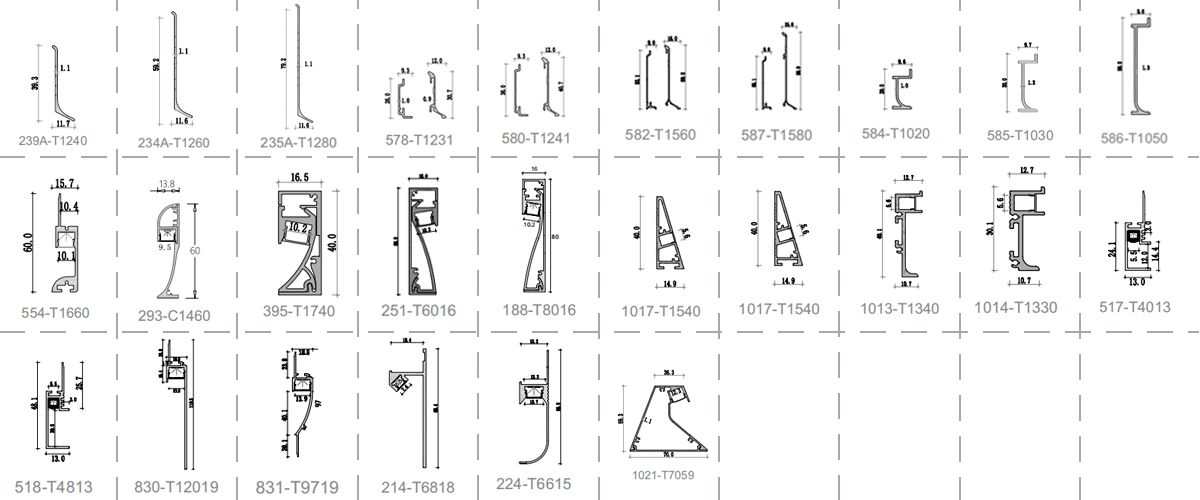

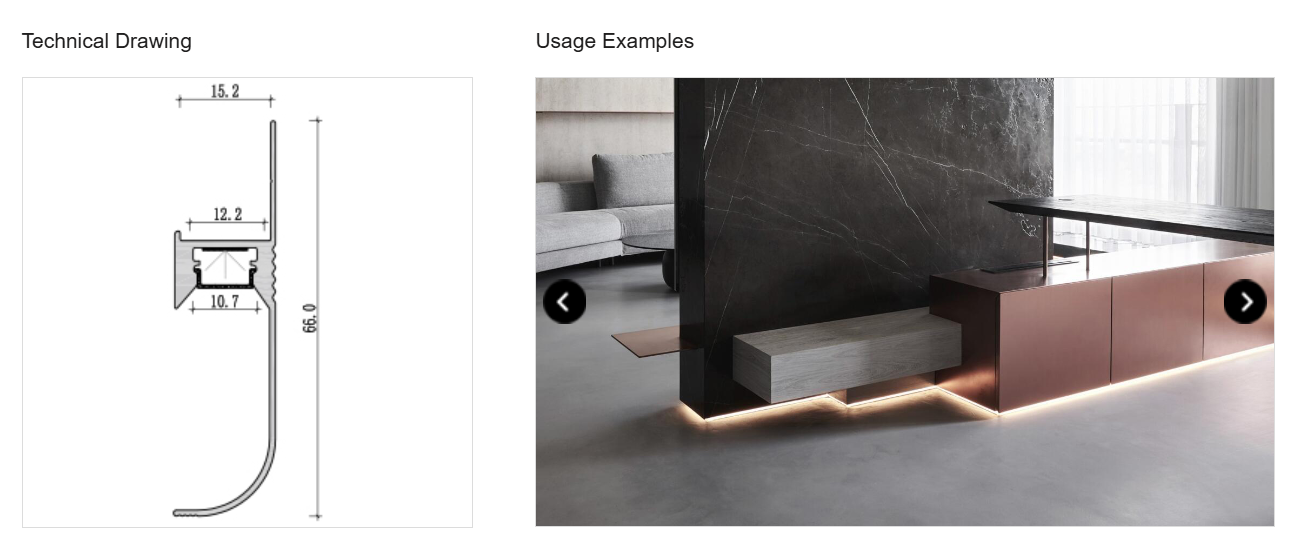

5.10,Skirting Light Series

(LED Baseboard Profile / Skirting Board LED Channel)

Applications: Baseboards, corridor guides, low-level lighting.

Ideal for: Smart home designers, public space renovators.

Advantages: Combines safety guidance and decoration; improves nighttime visibility.

Best Choice: Waterproof and dustproof skirting LED profiles.

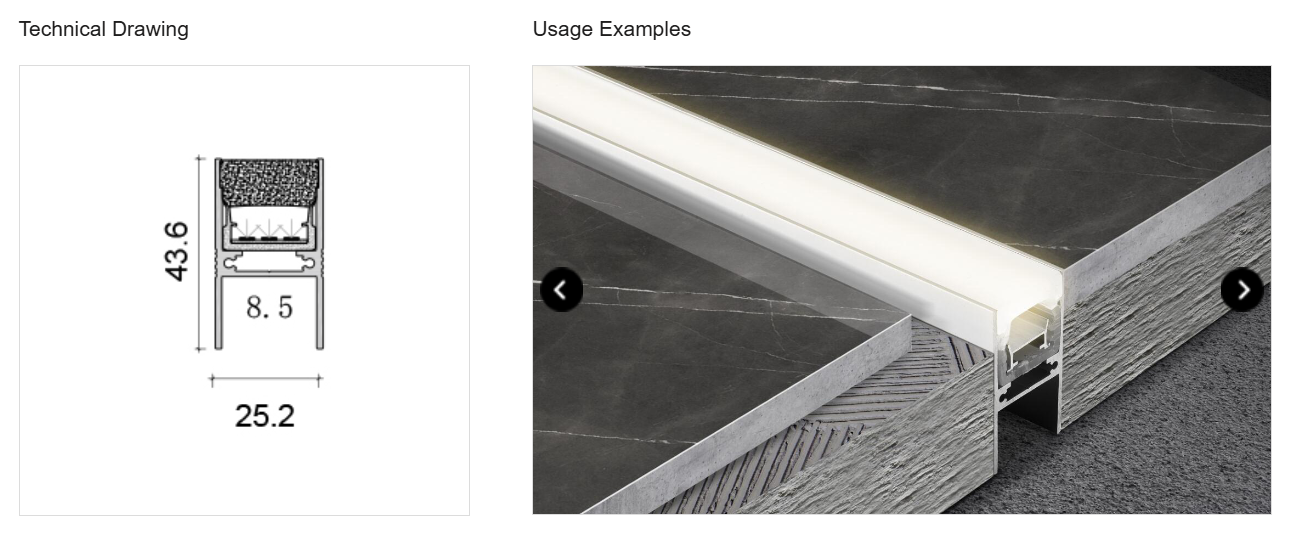

5.11,Stairs & Inground Light Series

(Stair LED Aluminum Profile / Inground LED Channel)

Applications: Stairs, walkways, outdoor floors, parking lots.

Ideal for: Outdoor space designers, landscape project contractors.

Advantages: Strong, waterproof, anti-slip; safe for walking and driving at night.

Best Choice: Thick waterproof profiles with anti-slip surface.

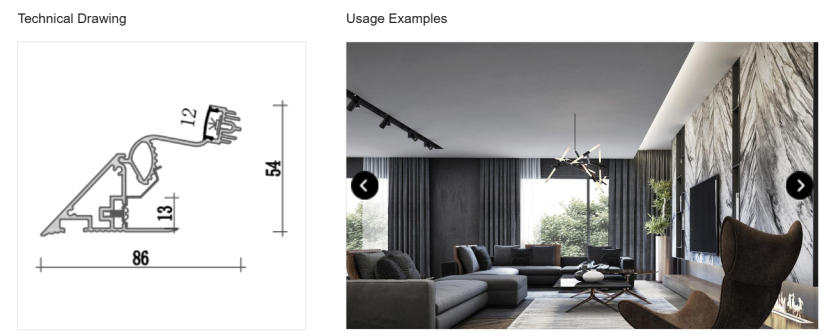

5.12,Magnetic Track & Anti-Glare Series

(LED Magnetic Track Channel / Anti-Glare Aluminum Profile)

Applications: Malls, offices, galleries, modern homes.

Ideal for: Shopfitters, retail space planners, interior lighting pros.

Advantages: Easy magnetic install; modular setup; anti-glare design for soft, comfortable light.

Best Choice: Use with magnetic lights; anti-glare louver profiles.

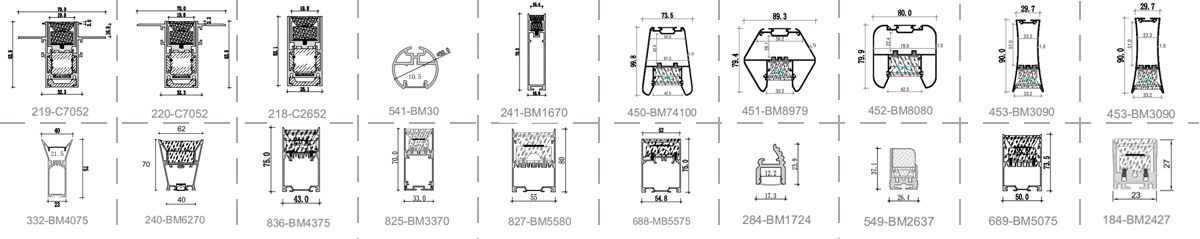

5.13,Professional Industrial Recessed Series

(Trimless LED Profile / Integrated Architectural Lighting Channel)

Applications: Commercial lighting projects, high-end architectural spaces, modern office buildings, premium shops.

Ideal for: Lighting designers, architectural contractors, commercial space planners.

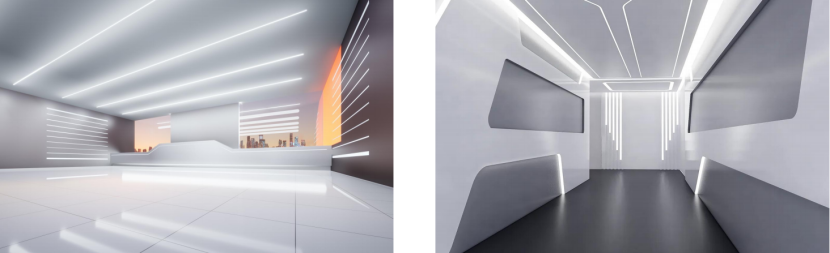

Advantages: Fully integrated architectural lighting system offering unprecedented visual possibilities through an invisible line. The profiles can be easily installed with a minimum depth of just 10mm, making them ideal for trimless, seamless effects. The almost unlimited three-dimensional matching options provide exceptional freedom to fulfill creative design ambitions.

Best Choice: Slim trimless profiles designed for minimal installation depth, compatible with various LED strip types for invisible and stylish lighting solutions.** Thick, sealed profiles for tough environments.

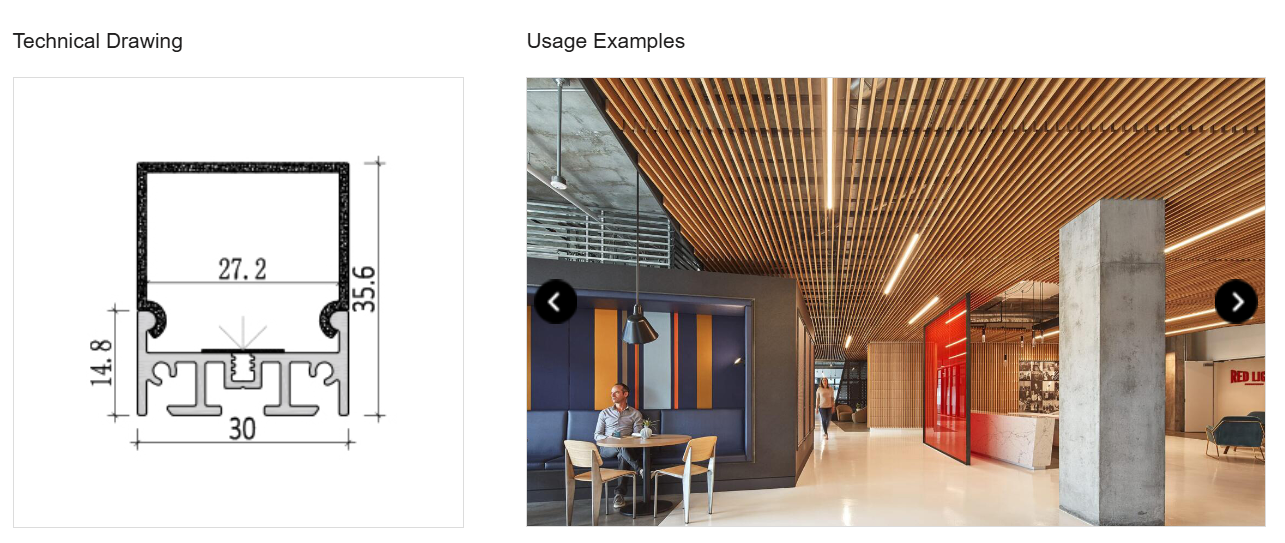

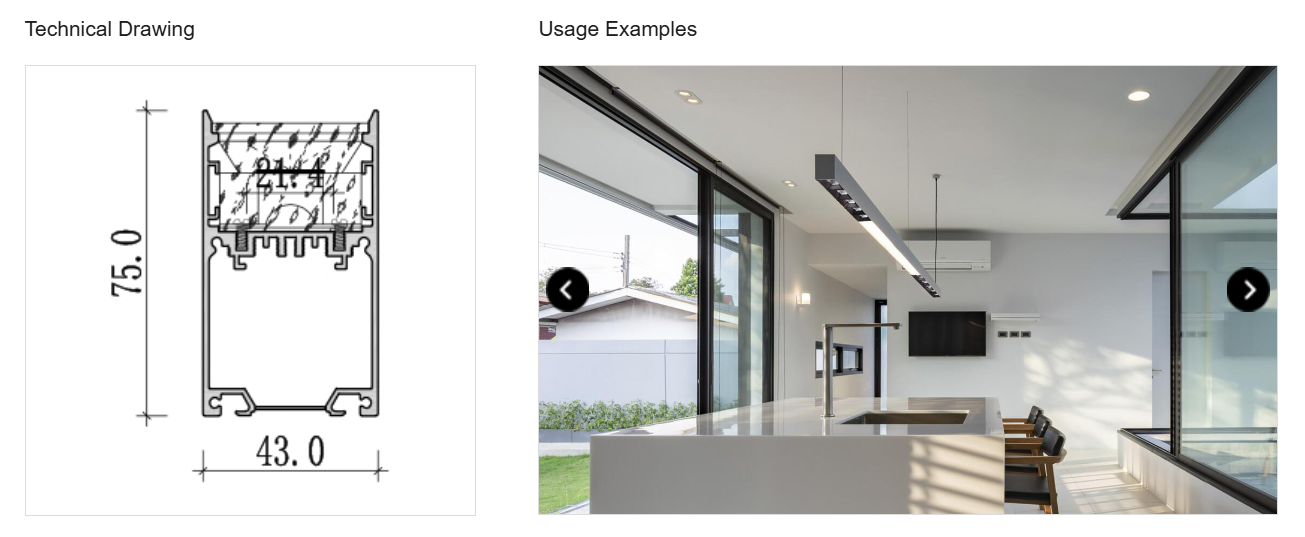

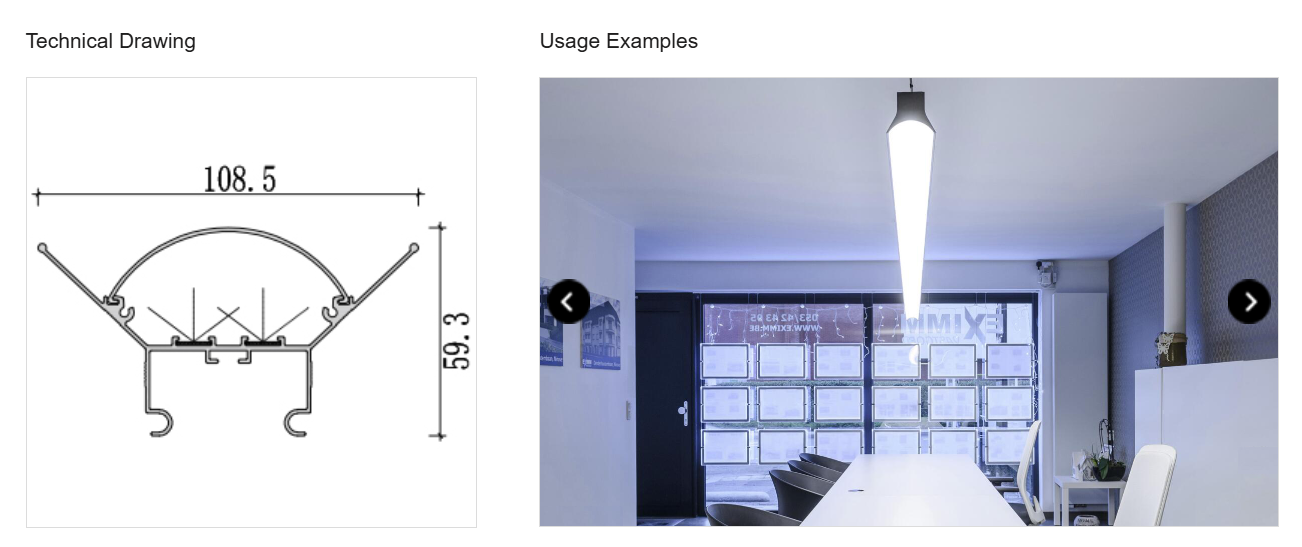

5.14,Suspended Series

(Suspended LED Profile / Hanging Aluminum Channel)

Applications: Offices, showrooms, restaurants, workshops.

Ideal for: General contractors, office fit-out companies.

Advantages: Suspended design for big spaces; wide and uniform light.

Best Choice: High-power suspended profiles with anti-glare covers.

5.15,Tri-Proof Light Series

(Waterproof LED Aluminum Profile / Tri-Proof LED Channel)

Applications: Garages, basements, factories, outdoors.

Ideal for: Industrial contractors, storage facility builders.

Advantages: Waterproof, dustproof, anti-corrosion; built for harsh places.

Best Choice: Profiles rated IP65 or higher.

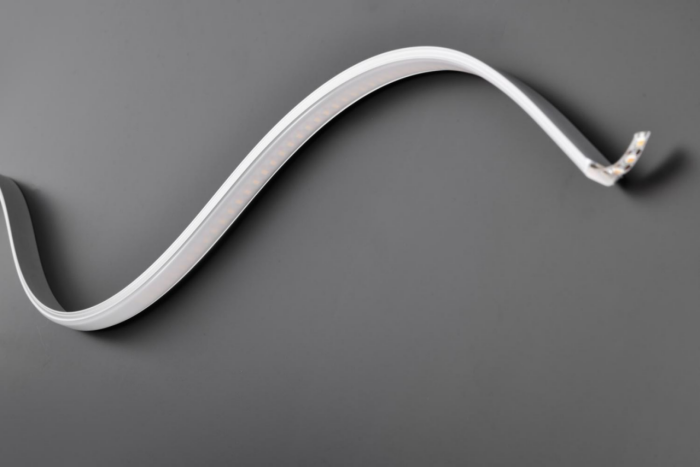

5.16,DIY Customized Bending Style Series

(Flexible LED Aluminum Profile / Bendable LED Channel)

Applications: Custom decor, art displays, creative installations.

Ideal for: Art show designers, DIY enthusiasts.

Advantages: Bendable, shape-free; perfect for curves and unique designs.

Best Choice: Ultra-flexible profiles for soft LED strips.

5.17,Flexible LED Aluminum Channel

Bendable LED Profile for Creative Curved Lighting

Curved ceiling or wall designs – Ideal for modern architecture or feature lighting

Round mirrors and vanity outlines – Perfect for soft-edge backlighting

Archways and staircases – Adds elegant linear light flow to complex surfaces

Curved furniture, reception desks, or display cabinets – Enhances high-end retail and hospitality design

Custom signage and art installations – Flexible enough for artistic shapes and branding

DIY lighting projects – Easily adapted to creative home improvement needs

Who Benefits from Using Flexible LED Channels:

Interior designers & architects – For seamless light integration on curves and arcs

Lighting designers – Looking for clean, dot-free linear lighting with creative freedom

Custom furniture makers – Wanting to embed lighting into round or non-linear surfaces

Retail shopfitters & display builders – For attention-grabbing visual merchandising

LED strip wholesalers & installers – Offering flexible solutions to clients with unique layouts

Homeowners & DIY users – Seeking elegant and easy-to-install curved lighting lines

Bendable and Versatile

Adapts to concave or convex surfaces (in one direction) – perfect for irregular shapes.

Sleek & Lightweight Design

Easy to cut, carry, and install. Compatible with most LED strips (5mm–10mm and COB types).

Improves Lighting Performance

Works with milky or frosted diffusers to soften the light and reduce glare or visible dots.

Efficient Heat Dissipation

Aluminum body draws heat away from LED strips, helping prolong their lifespan.

Professional Look & Finish

Hidden mounting design ensures a clean and modern aesthetic.

Customizable Lengths

Can be easily cut to size; supports custom bending radius on request.

6.How to choose Aluminum Profile?

LED Aluminum Profiles (also known as LED Channels) act as the "protective armor" for LED strip lights. They not only enhance the lighting performance but also directly impact the overall quality of the space’s light environment. Choosing the right LED profile can significantly extend the lifespan of LED strips, improve heat dissipation, enhance aesthetics, and even elevate the design feel of the entire space.

So, what should you consider when selecting an LED aluminum profile?

LEDworker summarizes 9 key factors to help you make the right and confident choice.

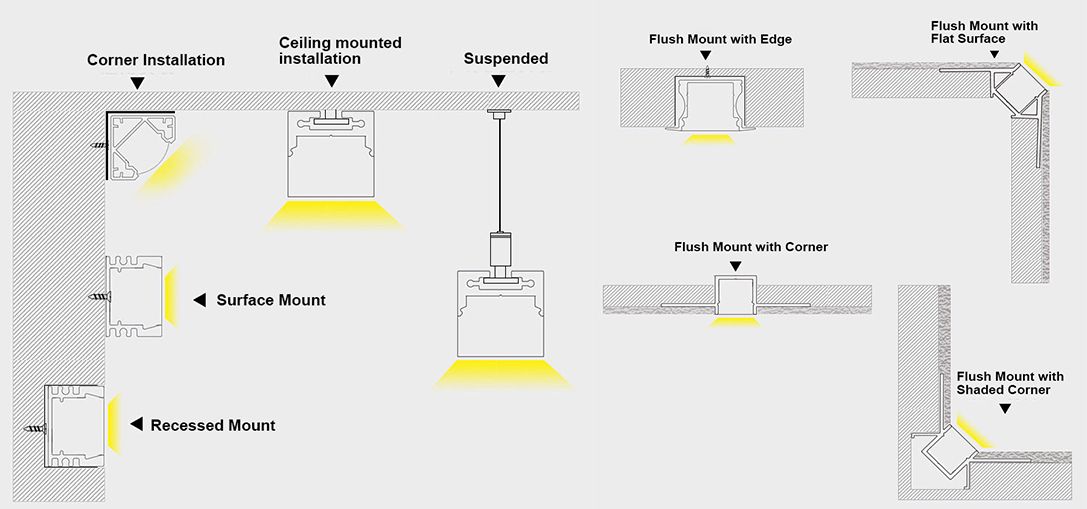

6.1, Choosing the Right Profile Shape

The first step is to determine the shape of the LED aluminum profile — Surface Mounted or Corner Type — depending on your installation needs.

The most popular type, ideal for flat surfaces such as walls, ceilings, or furniture without the need for recessing.

Suitable for hidden installations in ceilings, cabinets, or walls for a clean, flush look.

Designed for corners with a 45-degree lighting angle, perfect for cabinet edges, wall joints, or display units.

Built for durability with load-bearing, anti-slip, and dustproof features, making it ideal for stairs or flooring installations.

Specially made for high-end architectural applications, offering a seamless, frameless, and minimalist visual effect when embedded.

Additionally, similar shapes may come in various sizes or with/without flanges, so choosing the exact type depends on the specific installation area and design requirements.

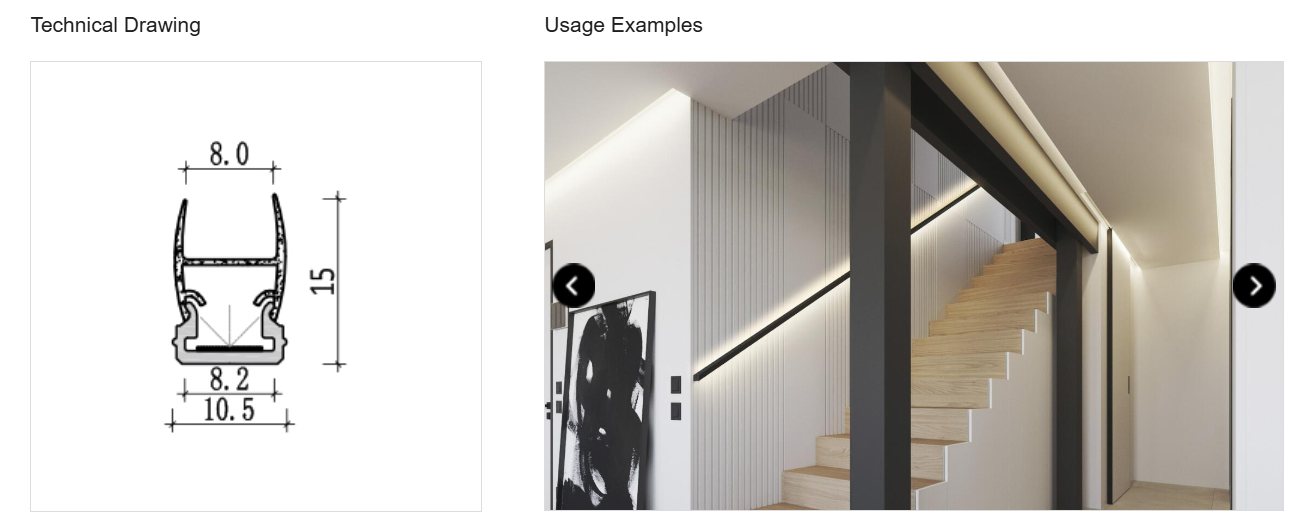

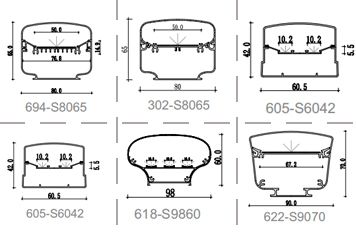

6.2 Choosing the Right Size of LED Aluminum Profile

After confirming the shape of the LED aluminum profile, the next important step is to determine the size. Even for similar profile shapes, there are various sizes available. When selecting the size, consider the following three key factors:

The length of the aluminum profile should match the specific installation space. Standard lengths include 1 meter, 2 meters, and 3 meters, but custom lengths such as 1.5 meters or 1.8 meters are also available upon request.

Keep in mind the transportation cost and convenience—profiles longer than 2 meters often lead to higher shipping fees and more challenging installation processes. A flexible solution, like combining two 1.5-meter profiles instead of a single 3-meter piece, can balance both cost-effectiveness and practicality.

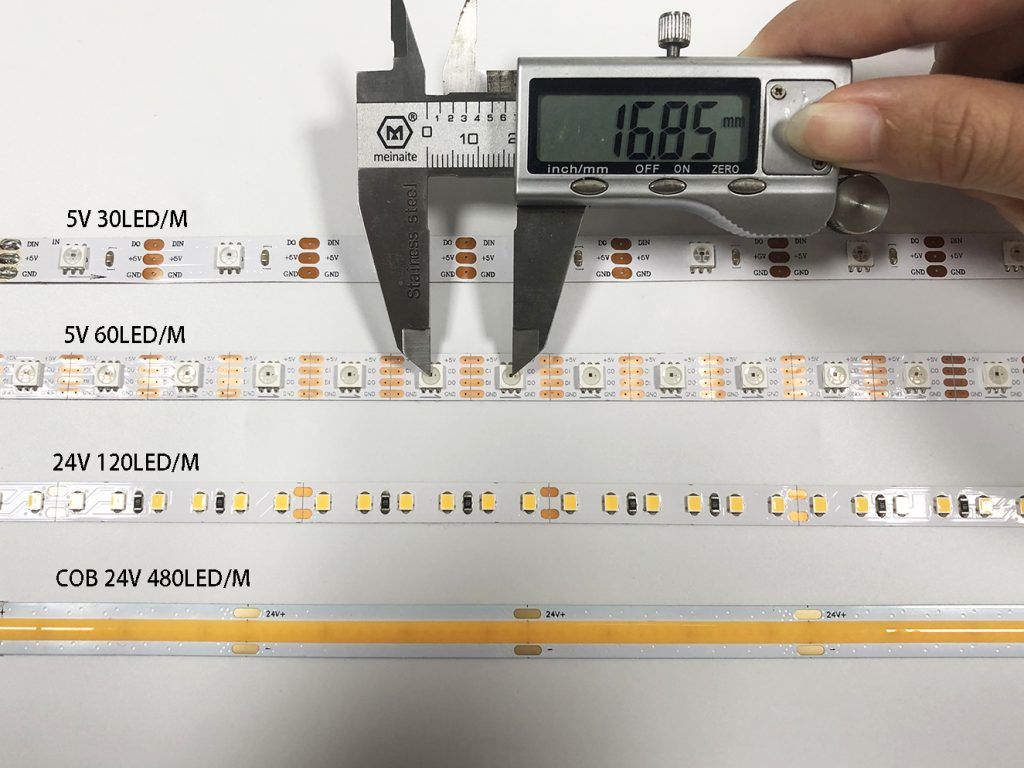

The internal width is a crucial but often overlooked factor. It must accommodate the LED strip width comfortably. Common LED strip widths include 5mm, 8mm, 10mm, 12mm, and even 20mm or wider.

To ensure easy installation, the internal width of the profile should be at least 0.5–1mm wider than the LED strip to prevent a tight fit or difficult assembly.

For high-power or dual-row LED strip applications, profiles with internal widths of 20mm, 30mm, or more are recommended to allow enough space and ensure proper heat dissipation.

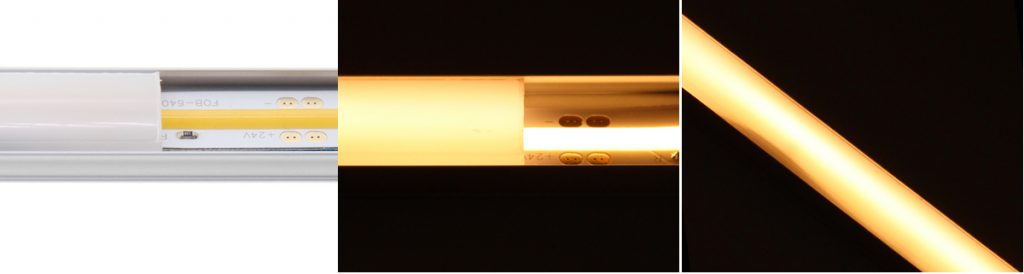

The depth of the aluminum profile affects the lighting performance. A deeper profile results in softer, more uniform light with less visible hotspots, though brightness may slightly decrease.

For projects that require dotless lighting effects—such as cabinet lighting, showcase displays, or architectural accents—deep profiles or COB LED strips are ideal choices for improving light uniformity.

On the other hand, if brightness is the top priority, shallow profiles paired with transparent diffusers may be more suitable.

For customers seeking a perfect balance between high brightness and no visible light spots, LEDworker Lighting offers customized solutions—carefully matching diffuser types, LED strip specifications, and profile depths to meet any lighting design requirement flawlessly.

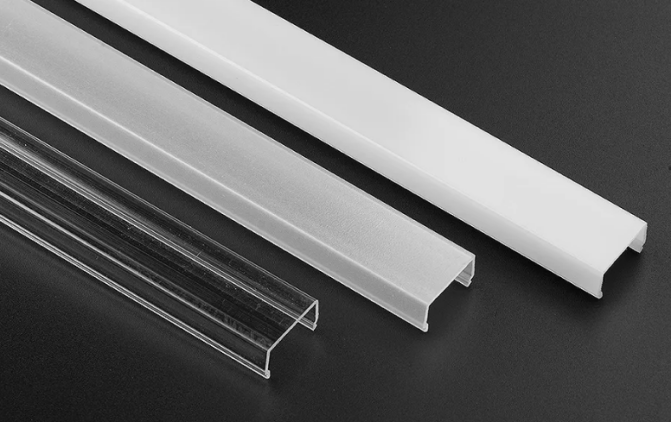

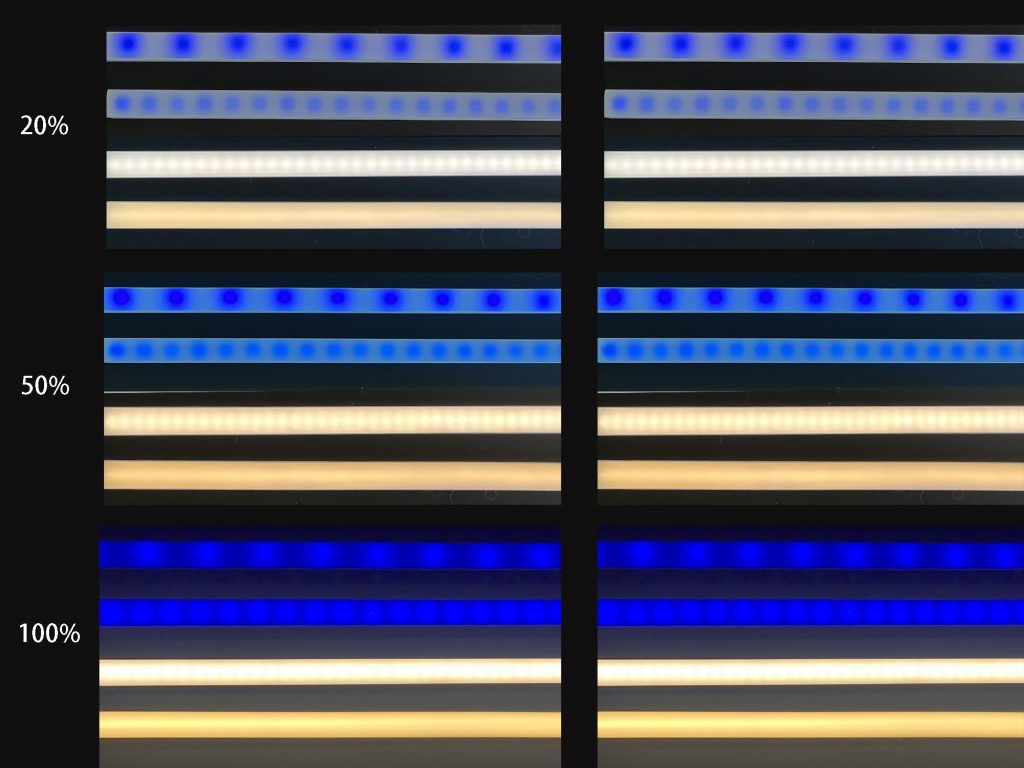

6.3 Choosing the Right Diffuser Cover for LED Profiles

The diffuser cover of an LED aluminum profile not only protects the internal LED strip from dust, moisture, and UV radiation, but also plays a key role in determining the final lighting effect. The material and transparency level of the PC diffuser directly influence brightness, light distribution, and visual comfort.

There are several common types of diffuser covers available:

Provides the highest light transmittance and brightness.

Ideal for display lighting or areas where maximum illumination is needed.

Delivers a soft, gentle light output.

Suitable for home, office, or general ambient lighting applications where glare reduction is important.

The most popular option in many lighting projects.

Ensures even light distribution with no visible LED hot spots, offering a clean and uniform glow.

Widely used in architectural and interior lighting where visual comfort matters.

Invisible when the light is off, creating a sleek and minimalist appearance.

Perfect for modern or concealed lighting designs.

Adjusts the beam angle to create focused or directional lighting effects.

Recommended for accent lighting, task lighting, or display showcases.

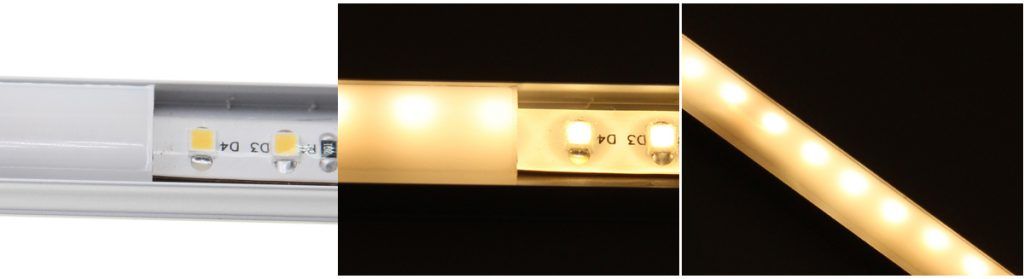

For COB LED strips, using a milky or frosted cover is highly recommended. This combination enhances light uniformity, eliminates visible dots, and delivers a smooth, continuous lighting effect, making it ideal for applications that require high-quality, dotless illumination.

6.4 Selecting the Right LED Strip for Your Aluminum Profile

A high-quality LED aluminum profile works best when paired with a suitable LED strip. When choosing an LED strip, the following factors must be carefully considered to ensure perfect compatibility and optimal performance:

(1)Color Options

Choose according to your project’s lighting needs:

The right color selection helps achieve the desired ambience, dynamic effects, or functional lighting.

(2)Voltage

Common operating voltages include 5V, 12V, and 24V.

The LED strip voltage must match the power supply unit to ensure safety and efficiency.

(3)Width

The LED strip width must precisely fit the internal width of the aluminum profile.

Typical widths include 5mm, 8mm, 10mm, 12mm, 20mm, depending on the project and profile design.

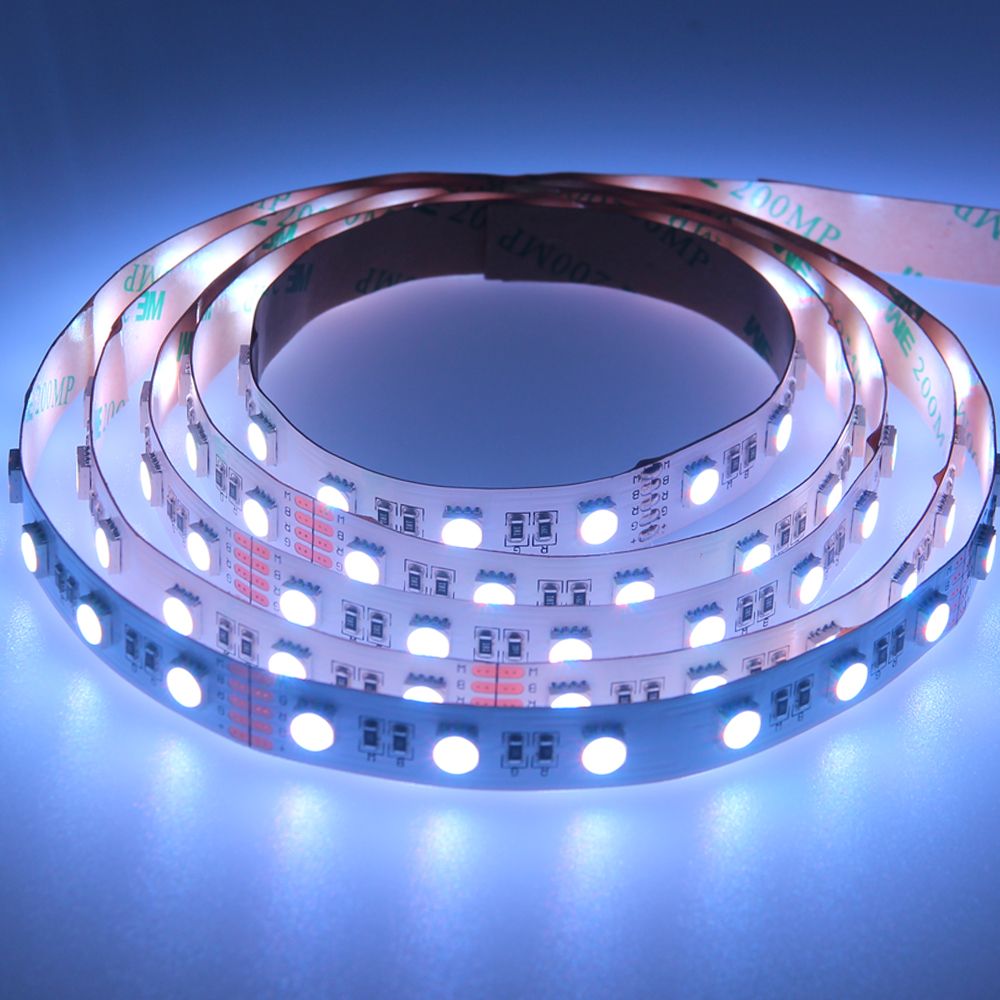

(4)LED Density

Refers to the number of LEDs per meter, such as 30 LEDs/m, 60 LEDs/m, 120 LEDs/m, 240 LEDs/m or COB (Chip On Board) LED strips.

Higher LED density or COB LED strips deliver smoother, dot-free lighting, ideal for applications demanding uniform illumination.

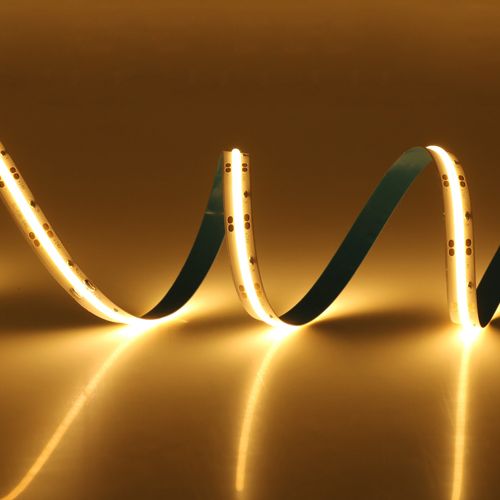

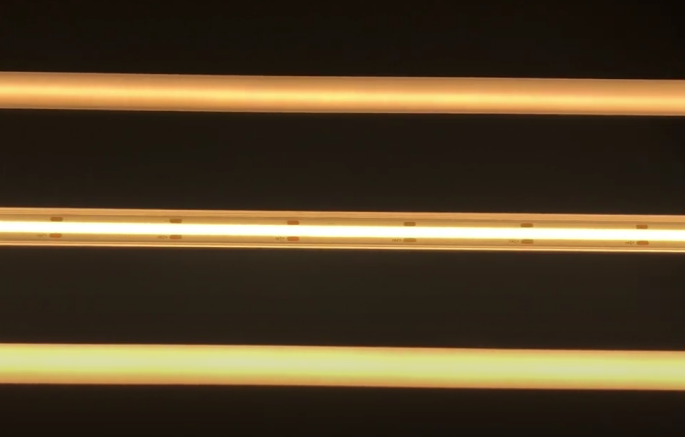

Highly Recommended: COB LED Strip

2835 SMD LED Strip Aluminum Profile

COB LED Strip Aluminum Profile

COB (Chip On Board) LED strips feature ultra-high LED density, delivering dot-free, smooth, and seamless illumination without any visible light spots or graininess.

COB LED strips are compatible with all types of aluminum profiles, whether deep or shallow, and work perfectly with various diffuser covers—clear, frosted, milky, or black—allowing complete flexibility in lighting design.

Thanks to their superior light uniformity and soft glow, COB LED strips have become the top choice for lighting designers, architects, and home improvement projects in recent years. Whether for cabinet lighting, showcase displays, or modern interior decoration, COB LED strips ensure a "no dot, no shadow" perfect lighting effect that meets the highest visual and aesthetic standards.

7.Complete Guide to LED Aluminum Profile Applications | Where to Use LED Channels

LED aluminum profiles (also known as LED channels, LED strip housings, or LED extrusions) are essential accessories for LED strip installations. They not only protect LED strips but also enhance light distribution, heat dissipation, and overall design aesthetics. LED aluminum profiles are widely used in residential, commercial, industrial, architectural, and special lighting projects.

LED aluminum profiles are very popular in home lighting projects, including:

Cabinet and Kitchen Lighting

Installed under cabinets or inside cupboards to brighten workspaces and improve kitchen functionality.

Wardrobe, Shoe Cabinet, and Storage Lighting

Integrated LED profiles with sensor lighting create a smart, modern storage solution.

Living Room and Bedroom Cove Lighting

Hidden LED channels in ceilings provide soft, ambient lighting and add depth to interior spaces.

Staircase and Skirting Board Lighting

LED profiles installed along stairs or baseboards increase safety and enhance night visibility.

In commercial environments, LED aluminum profiles elevate the visual appeal and brand image:

Storefront Window Displays

Paired with frosted or milky diffusers to create eye-catching product showcases.

Retail Shelves and Display Racks

Precision lighting design highlights product details and improves the shopping experience.

Office Spaces

Used in meeting rooms, lobbies, and open work areas for modern, glare-free general lighting.

Hotels and Restaurants

Ideal for walls, ceilings, and under-table lighting to build cozy, elegant, or upscale atmospheres.

Building Outline Lighting

Waterproof LED aluminum profiles outline building exteriors and make structures stand out at night.

Outdoor Pathways and Landscaping

Weather-resistant profiles illuminate garden paths, walkways, and railings for safety and beauty.

Stair Tread Lighting

Special stair LED profiles ensure anti-slip safety and aesthetic appeal in indoor and outdoor steps.

Cleanrooms and Laboratories

Profiles offer dust-proof and moisture-resistant lighting solutions ideal for controlled environments.

Medical Facilities

Hygienic and easy-to-clean LED profiles are suitable for clinics, hospitals, and examination rooms.

Exhibitions and Trade Shows

Easy to install and dismantle, LED profiles with COB strips provide high uniformity and professional display lighting.

Smart Lighting Systems

Compatible with dimmable and color-changing LED strips to create multi-scene intelligent lighting solutions.

Tailored Engineering Solutions

Available in ultra-narrow, three-sided, trimless, or recessed designs to meet unique architectural requirements.

8.How to Install LED Aluminum Profiles?A Complete Step-by-Step Guide

In LED strip lighting projects, LED aluminum profiles (also called LED channels or LED extrusions) play a crucial role in improving heat dissipation, protecting LED strips, optimizing light diffusion, and enhancing the overall design aesthetic. Correct installation ensures these profiles perform at their best. This guide provides a detailed breakdown on how to properly install LED aluminum profiles.

Before starting the installation, prepare the following items:

- Selected LED aluminum profiles with PC diffusers

- Compatible LED strips (matched in width, length, and voltage)

- Power supply or transformer

- Drill, screwdriver, scissors, utility knife, measuring tape

- Mounting clips, 3M double-sided tape, screws, wall plugs, adhesive

- Suspension wires, hanging kits (for pendant installations)

- End caps, covers, and cable outlets as needed

Measure the installation area carefully and cut the LED aluminum profile and LED strip to the required lengths.

For multiple connected profiles, leave a small expansion gap (2–3mm) to avoid thermal expansion issues.

Ensure the mounting surface is clean, smooth, and dry. Use isopropyl alcohol to remove dust or grease if necessary.

Depending on your space and design needs, LED aluminum profiles can be installed in various ways:

8.3.1. Surface Mounted Installation

This is the most common and straightforward method, ideal for walls, ceilings, cabinets, and display cases.

Clip Installation: Secure mounting clips onto the surface with screws, then snap the aluminum profile into place. This method allows for easy removal and repositioning.

3M Double-Sided Tape: Suitable for lightweight profiles and smooth surfaces. Always clean the surface before applying the tape to ensure strong adhesion.

Direct Screw Mounting: For a secure, permanent solution, drill through the profile and fix it directly to the mounting surface using screws.

8.3.2. Recessed (Flush) Installation

Perfect for creating seamless, built-in lighting in walls, ceilings, or furniture.

A groove must be pre-cut to match the profile's size.

Many recessed profiles feature “flange” or “wing” edges that help cover minor imperfections or oversized openings for a clean finish.

Some profiles have dual-slot designs inside, allowing for adjustable mounting depth and optimized heat dissipation.

8.3.3. Corner Installation

Special corner profiles are designed for spaces like cabinet corners, stair edges, or room junctions, typically offering beam angles such as 30°, 45°, or 60°.

Corner profiles help eliminate “dark spots” often missed by traditional lighting.

A 45° profile, for example, features an angled internal base for improved light diffusion and enhanced thermal performance.

Mounting options include clips, adhesive, or screws for secure placement.

8.3.4.Pendant (Suspended) Installation

Widely used in modern office, retail, and exhibition spaces, pendant-mounted profiles create a stylish floating lighting effect.

Install using steel suspension wires, adjustable hanging kits, and brackets.

The height can be adjusted to suit various ceiling heights and design requirements.

Often combined with high-power COB LED strips for excellent uniformity and brightness.

Carefully stick the LED strip into the bottom of the aluminum profile.

Connect the LED strip to the power supply, ensuring voltage compatibility.

For corners or bends, use flexible connectors instead of bending the LED strip to avoid damage.

Avoid hanging the strip upside down without support to prevent detachment over time.

Choose the right diffuser (clear, frosted, milky, black, or lens type) and snap it onto the aluminum profile.

Install end caps, plugs, or cable outlets to complete the profile and protect against dust and moisture.

Check all connections to ensure they are secure and properly aligned.

Turn on the power to test the LED strip lighting.

Inspect the light output for consistency, brightness, and uniformity.

If necessary, adjust the LED strip or profile placement to achieve the desired lighting effect.

Though the installation process may seem simple, proper handling of LED aluminum profiles ensures maximum performance, safety, and visual impact. Whether for residential, commercial, or industrial lighting, selecting the right mounting method and following correct installation steps will extend the life of your LED strips and elevate your space’s overall design quality.

9.FAQ

LED aluminum profiles, also known as LED channels, LED strip housings, or LED strip light extrusions, are specially designed mounting solutions for LED strip lights. Made from high-quality extruded aluminum, these profiles are typically paired with PC diffusers to enhance lighting effects, provide physical protection, and extend the lifespan of LED strips.

https://youtu.be/x23A3YWEm1EIn general, standard LED aluminum profiles are not inherently waterproof. Their primary purpose is to provide structural support, heat dissipation, and enhanced lighting aesthetics. However, with the right design and components, it’s absolutely possible to achieve a waterproof lighting system — especially with our ground-mounted waterproof aluminum profile series.

✅ Our In-Ground Waterproof Aluminum Channel Series

We offer a specialized range of waterproof aluminum profiles designed specifically for outdoor and in-ground installations. These profiles feature:

Waterproof LED strips (IP65 / IP67 rated)

Sealed end caps with waterproof adhesive for tight closure

Waterproof connectors at all cable entry points

Robust construction that can withstand outdoor exposure and foot traffic

Ideal for: pathway lighting, garden edging, floor uplights, bathroom perimeters, and outdoor stairs

💡 Can Standard LED Channels Be Made Waterproof?

Yes, while standard aluminum profiles don’t come waterproof by default, you can enhance water resistance by:

Using IP-rated waterproof LED strips

Adding end caps with rubber seals

Applying waterproof silicone or sealant at all openings and seams

Choosing profiles with more enclosed or sealed designs

🌧 Recommended Installation Scenarios

|

Application Area |

Waterproofing Recommendation |

|

Indoor dry spaces |

Standard profile + regular LED strip |

|

Bathrooms/Kitchens |

Standard profile + waterproof LED strip + sealed end caps |

|

Balconies/Semi-outdoor |

Waterproof LED strip + sealed ends + added silicone sealant |

|

Outdoor or In-ground |

✅ Use our waterproof in-ground aluminum profile series + waterproof strip + connectors |

While regular LED aluminum profiles are not waterproof on their own, you can build a water-resistant system with the right accessories and proper sealing.

But for high-reliability outdoor or ground-level applications, we strongly recommend using our dedicated waterproof aluminum channel series, which has been engineered for durability, safety, and long-term performance in harsh environments.

How to Waterproof Your LED Aluminum Profile – Step by Step!

Aluminum profiles are metal materials made from aluminum alloy. They are produced by heating and extruding aluminum billets into various shapes such as U-shaped, L-shaped, or rectangular strips. These profiles can be used as structural supports, protective housings, or paired with LED strip lights.

The main material of aluminum profiles is aluminum alloy, which means adding other metals to pure aluminum to make it stronger and more durable. Common aluminum alloy grades include:

A2011 – Ideal for parts that require high-precision machining

A5052 – Excellent corrosion resistance, suitable for coastal or outdoor use

A6061 – High strength, often used in industrial structures

A6063 – Great for surface finishing; the most commonly used alloy for LED strip channels

A7075 – Extremely strong, widely used in aerospace and heavy-duty industries

Each aluminum alloy has its own characteristics and application scenarios, and the right grade should be selected based on the specific needs of your project.

An LED aluminum profile—also known as an LED channel, LED housing, or LED extrusion—doesn’t produce light by itself, but it plays a vital role in any LED strip lighting system. It works together with LED strips to improve heat dissipation, mounting, lighting effect, and protection.

Here’s how it works step by step:

- Helps with Heat Dissipation to Extend LED Lifespan

When LED strips operate, they generate heat. If the heat is not removed, it can reduce brightness, cause flickering, or shorten the lifespan of the LEDs.

Aluminum is a highly efficient heat conductor. An LED profile transfers heat away from the strip and keeps the LEDs running at a stable temperature. This helps maintain performance and extend the life of your lighting system.

- Provides Stable Mounting Support

The aluminum profile acts as a rigid support structure for the LED strip. It can be installed on walls, ceilings, cabinets, or other surfaces using clips, screws, adhesive, or brackets.

Once installed, the strip stays secure and won’t sag or fall off over time—safer and more professional-looking.

- Works with Diffusers to Soften the Light

LED profiles usually come with a PC diffuser cover—clear, frosted, milky white, or lens-style. These covers help to: Soften harsh light, Reduce glare,Eliminate visible LED dots, This creates a smooth, uniform lighting effect that’s ideal for homes, shops, offices, and displays.

- Offers Physical Protection from Dust and Moisture

The aluminum channel protects the LED strip from dust, moisture, and impact. This is especially helpful in kitchens, bathrooms, wardrobes, or hallways—places where the strip might be exposed to wear and tear.

- Improves the Look of Your Space

Beyond functionality, an LED profile gives your lighting a clean, finished, and modern appearance. Whether it’s surface-mounted, recessed, corner-mounted, or suspended, the result is a more elegant and seamless light integration into your space.

An LED aluminum profile doesn’t emit light, but it’s an essential part of making your LED strip system safer, cooler, longer-lasting, and more visually appealing. It works by dissipating heat, supporting installation, protecting the strip, and enhancing the light quality.

By Application:

- LED Aluminum Profiles (LED Channels)

Specifically designed for LED strip lights, these profiles help with heat dissipation, secure mounting, and light diffusion. They are commonly used in cabinets, ceilings, and display lighting.

- Industrial Aluminum Profiles (Structural Profiles)

Used for equipment frames, assembly lines, and machine structures. They offer high strength and modular assembly. Common sizes include 30x30mm, 40x40mm, 45x45mm, etc.

- Architectural Aluminum Profiles

Used in doors, windows, curtain walls, baseboards, and louvers for interior and exterior building decoration.

- Furniture Aluminum Profiles

Used for wardrobe frames, cabinet edges, and furniture connectors. Lightweight and aesthetically pleasing, suitable for modern home design.

[Step 1 – Prepare the channel & LED strip]

Start by measuring and cutting both the aluminum profile and LED strip to fit your desired installation area. Make sure the surface is clean and dry before applying.

Tips: Different LED strips have fixed cut points, which may not match the channel length.

We recommend cut-free strips – easy to trim, easier to install.

[Step 2 – Apply the LED strip]

Peel off the adhesive backing and place the LED strip inside the channel.

[Step 3 – Attach the diffuser cover]

Once the strip is in place, snap on the diffuser cover for a smooth, finished look.

This also helps to soften the light and protect the LEDs from dust.

[Step 4 – Mount the aluminum channel]

Secure the aluminum channel using screws or mounting clips.

In this video, we are using mounting clips for demonstration purposes only. No actual installation is performed.

This provides solid support and helps with heat dissipation.

[Step 5 – Power it up & test]

Connect the LED strip to the power supply and test the lighting.

Adjust if necessary, and enjoy your sleek and modern lighting setup.

When installing LED aluminum channels (also known as LED profiles), you often need to cut them to fit specific lengths—whether it’s for cabinets, ceilings, walls, or display cases. Here's a step-by-step guide on how to cut LED channels safely and accurately.

- Tools You’ll Need

To cut LED aluminum channels properly, prepare the following tools:

✂ Saw tools:

Fine-tooth hacksaw (manual)

Miter saw or circular saw with an aluminum-cutting blade (recommended for clean cuts)

📏 Measuring tape or ruler

✏️ Marker or pencil (for cutting marks)

🧤 Safety gear: gloves and safety goggles

- Cutting Steps

Step 1: Measure the Length

Use a tape measure to mark the desired length on the aluminum channel. Double-check your measurement before cutting.

Step 2: Secure the Channel

Clamp the channel firmly on a workbench to prevent movement during cutting.

Step 3: Cut the Aluminum

Use a miter saw or a fine-tooth hand saw to cut along the marked line.

Tip: Cut slowly and steadily to avoid rough edges or deformation.

Step 4: Smooth the Edges (Optional)

Use sandpaper or a metal file to gently smooth the cut ends. This helps with safety and a cleaner fit during installation.

Step 5: Clean Up

Remove any aluminum shavings or dust before installing the profile.

- Additional Tips

Only cut the aluminum part—remove the LED strip and PC diffuser cover before cutting.

The diffuser cover can also be cut with a saw or plastic cutting tool. Handle gently to avoid cracking.

Try to keep length errors within ±1mm for seamless alignment or corner connections.

Conclusion

Cutting LED aluminum channels is easy with the right tools and careful measurement. For best results, use a fine-tooth saw, work slowly, and always prioritize safety. If precision is critical, consider having it cut by a professional.

Technically, LED strip lights can work without aluminum profiles, but in most applications, using an aluminum profile is highly recommended. It provides multiple benefits in terms of performance, durability, appearance, and safety—especially for high-brightness, long-run, or professional installations.

Why Use Aluminum Profiles with LED Strips?

✅ 1. Better Heat Dissipation = Longer Lifespan

LED strips generate heat during operation. If the heat is not properly managed, it can lead to brightness loss, color shifting, or even failure.

Aluminum profiles act as heat sinks, helping dissipate heat and extend the life of the LEDs.

✅ 2. Stable and Professional Installation

Profiles provide a solid structure to mount the LED strip securely. They can be installed using clips, screws, or adhesive. This makes the setup neater, safer, and more reliable over time.

✅ 3. Improved Light Quality and Comfort

When used with a diffuser (frosted or milky cover), aluminum profiles soften the light and help eliminate visible LED dots, reducing glare.

This is ideal for homes, offices, cabinets, and display cases.

✅ 4. Protection from Dust and Moisture

An aluminum channel with a cover protects the LED strip from dust, humidity, and grease, which is especially useful in kitchens, bathrooms, or workshops.

✅ 5. Cleaner Look and Better Design Integration

Modern lighting design favors “light without seeing the fixture.” Aluminum profiles can be recessed, surface-mounted, or corner-mounted to create sleek, high-end lighting effects.

When Can You Skip the Aluminum Profile?

For temporary lighting or testing

In low-power, low-heat setups

If the installation area is hidden and appearance doesn’t matter

Even in these cases, using thermal tape or aluminum backing is still recommended for minimal heat management.

While LED strips don’t absolutely require aluminum profiles, they’re a smart and professional choice for most lighting applications.

They help make your lighting system cooler, safer, more durable, and more visually appealing.

An aluminum channel is a U-shaped or specially designed metal profile made from aluminum alloy. It’s widely used in construction, furniture, lighting, and industrial applications due to its lightweight, strength, and resistance to rust.

Below are the most common uses of aluminum channels:

🔧 1. LED Lighting Installations

One of the most popular uses today is in LED strip lighting. Aluminum channels (also called LED profiles) help:

Mount and hold LED strips securely

Dissipate heat to extend LED lifespan

Improve light quality with diffuser covers

Create clean, modern lighting designs

They’re used in cabinets, ceilings, under shelves, staircases, and more.

🏗️ 2. Architectural and Building Applications

In construction, aluminum channels are used for:

Wall trims

Ceiling details

Partition framing

Door and window structures

Curtain wall support

Thanks to their corrosion resistance and sleek appearance, they’re a top choice for interior and exterior decoration.

🪑 3. Furniture and Cabinetry

Aluminum channels are often integrated into furniture to:

Add structural support

Serve as frame components

Hold LED lighting in kitchen cabinets or wardrobes

Provide decorative trims or handles

⚙️ 4. Industrial and Mechanical Use

In industrial environments, aluminum channels are used in:

Machinery frames

Conveyor systems

Custom enclosures

Workstations or tool benches

They’re valued for their lightweight strength and easy machining.

💡 5. DIY and Custom Projects

Because aluminum is easy to cut, drill, and assemble, aluminum channels are great for:

Custom lighting setups

3D printer frames

Home improvement projects

Display units and signage

Aluminum channels are versatile, durable, and lightweight components used for mounting, framing, protecting, or enhancing other structures or systems—especially LED lighting. Whether in homes, offices, factories, or shops, they help combine function with clean design.