- Professional LED Strips: Prevent Voltage Drop, Ensure Even Brightness

- What is Voltage Drop in LED Strips?

- Key Factors Affecting Voltage Drop

- Key Factors Affecting Voltage Drop in LED Strips

- Controlling LED Strip Voltage Drop: Finding the Optimal Balance

- Finding Balance Through Other Design Factors

- LEDWorker Lighting: Controlling Voltage Drop from the Design Stage for Consistent Performance

- FAQ

- REQUEST A QUOTE

Professional LED Strips: Prevent Voltage Drop, Ensure Even Brightness

What is Voltage Drop in LED Strips?

When electricity flows from the power supply to the lighting device (such as custom LED strip lights), it passes through wires, PCB boards, and connectors. Each of these components has resistance, which consumes a small portion of the voltage.

As a result, in an LED strip, the farther it is from the power source, the lower the voltage becomes. This reduction in voltage is what we call “voltage drop.”

Example with LED Strips:

Let’s say the power supply outputs 12V:At the start of the LED strip, the voltage might measure 12.0V.After 5 meters, due to circuit resistance, the voltage could drop to 11.2V.In this case, the voltage drop = 12.0V – 11.2V = 0.8V.

This is a common issue in both standard and customizable LED light strips. That’s why custom LED strip manufacturers often recommend proper wiring design and power distribution when creating custom made LED strip lights, especially for long installations.

📩 Have a project suffering from voltage drop? Contact our engineering team to get a tailored wiring & power distribution plan.

A more detailed explanation

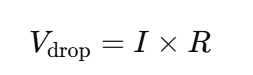

Current flows like water in a pipe, and voltage is the “pressure” that pushes it.

When custom LED strip lights operate, the power supply drives current through wires, PCB traces, solder joints, and connectors. Each path has some resistance—even very small—and as current passes through that resistance, part of the voltage is consumed (Ohm’s Law:

where I is current and R is total resistance).

This is why longer runs or higher-power setups (e.g., custom size LED strips, custom RGB LED strips) are more prone to voltage drop than short segments. It’s a core consideration for custom LED strip manufacturers when designing customizable LED light strips or custom made LED strip lights for consistent brightness end-to-end.

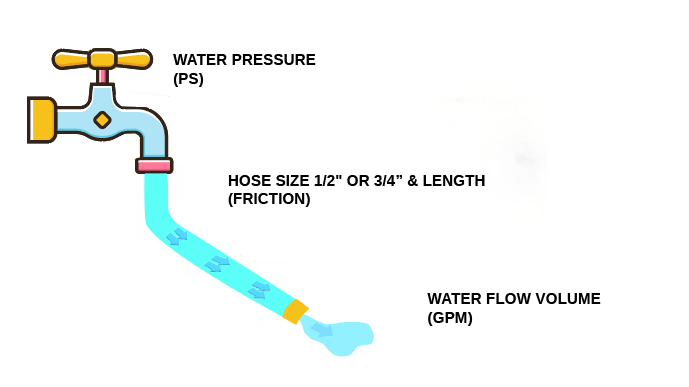

Using the water flow analogy

Voltage drop in custom LED strip lights can be compared to a river losing depth downstream.

Imagine current as water flow, and voltage as the water’s height.

Water starts from the pump (the power supply) and flows downstream (to the far end of the LED strip). Along the way, it passes through a long riverbed — the wires, copper traces, and connectors. Every section of the riverbed adds friction and resistance (just like electrical resistance), consuming part of the water’s height.As a result, the farther you are from the pump, the lower the water level becomes and the weaker the flow.

Similarly, in customizable LED light strips, the farther from the power input, the lower the voltage, which makes the LEDs at the end appear dimmer.

Key Factors Affecting Voltage Drop

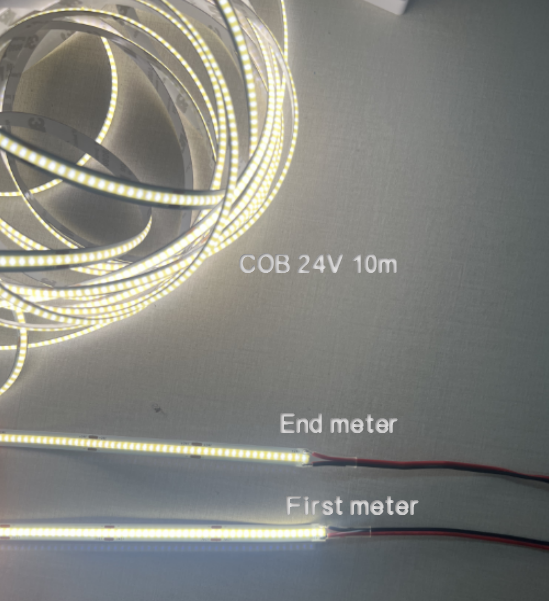

How Voltage Drop Appears in LED Strips:

Voltage drop—also known as voltage reduction—refers to the gradual decrease in voltage as current flows from the power supply through the LED strip. On LED strips light , this usually appears in the following ways:

(1)Uneven Brightness

The LEDs closer to the power input shine normally, while those farther away appear noticeably dimmer. This is especially obvious in long runs of LED strip lights or in high-power applications.

(2)Color Temperature Shift

When voltage is insufficient, LEDs may emit warmer or reddish tones, causing the color temperature to deviate from the intended design. This issue is particularly important for custom color LED light strips used in high-end interiors.

(3)Flickering or Instability

If the voltage drop is severe, some LEDs may flicker or even shut off intermittently.

(4)Increased Overheating Risk

To compensate for voltage drop, some drivers may push higher current output, which can lead to localized overheating.

Not sure which LED strip specification best fits your project? Email us and we’ll recommend the right copper thickness, voltage, and layout.

Key Factors Affecting Voltage Drop in LED Strips

Voltage drop is not simply the “temperament” of an LED strip—it’s the result of several combined factors:

(1) LED Strip Length

The longer the strip, the more significant the voltage drop. As current travels through the copper foil or wires, the resistance accumulates with distance.

Low-voltage options (such as 5V or 12V) are particularly sensitive—excessive length may cause the LEDs at the far end to appear dimmer.

High-voltage strips (such as 24V or 220V) tolerate longer runs, but for large-scale projects, voltage drop must still be considered.

(2) PCB Copper Thickness

The thickness of the copper on the PCB plays a major role:

Thinner copper increases resistance, worsening voltage drop.

Common specs include single-sided vs. double-sided boards—double-sided paths reduce resistance.

Copper thickness options like 1OZ, 2OZ, or 3OZ: the thicker the copper, the lower the resistance, and the better the strip handles current.

For high-power custom made led strip lights or long runs of custom rgb led strips, proper copper thickness dramatically improves uniformity and reduces voltage drop issues.

(3) Current and Resistance

| Factor | Effect | Typical Situation | Countermeasure |

| Current | The higher the current, the more significant the voltage drop | Long strips / High-power strips | Shorten series length / Add more power input points |

| Resistance | The higher the resistance, the greater the voltage drop | Thin copper wires / Long-distance wiring | Increase copper thickness / Use thicker wires |

| Combined effect | High-power or low-voltage strips combined with long-distance wiring cause the most severe voltage drop | Large-scale installations | Add more power input points / Optimize wiring layout |

(4) Operating Voltage

Low-voltage LED strips (5V or 12V custom LED strip lights) are more sensitive to voltage drop because the percentage decrease is higher. High-voltage strips (24V or 220V custom rgb lights) experience smaller relative drops and are more stable. When designing low-voltage strips, consider the intended run length, wiring layout, and power input points to balance performance and cost.

(5) Number of LEDs

The more LEDs on a strip, the higher the total current, which increases cumulative voltage drop. High-density strips (e.g., 120 LEDs/meter) are more prone to dimming at the far end compared to low-density strips (e.g., 30 LEDs/meter).

(6) LED Type (Number of Color Channels)

Single-color, RGB, RGBW, RGBCCT, or other multi-channel LEDs carry varying currents per channel. The more channels per LED, the more complex the current flow, and the higher the chance of voltage drop. Multi-channel LED strips require careful consideration of each channel’s current, especially for long or high-density installations.

(7) Other Factors

Connection method and quality: Multiple connections, poor solder joints, or loose connectors can increase localized voltage drop.

Ambient temperature: Higher temperatures can change resistance in wires and LED components, worsening voltage drop.

Wire choice: Using undersized or excessively long wires also increases voltage drop.

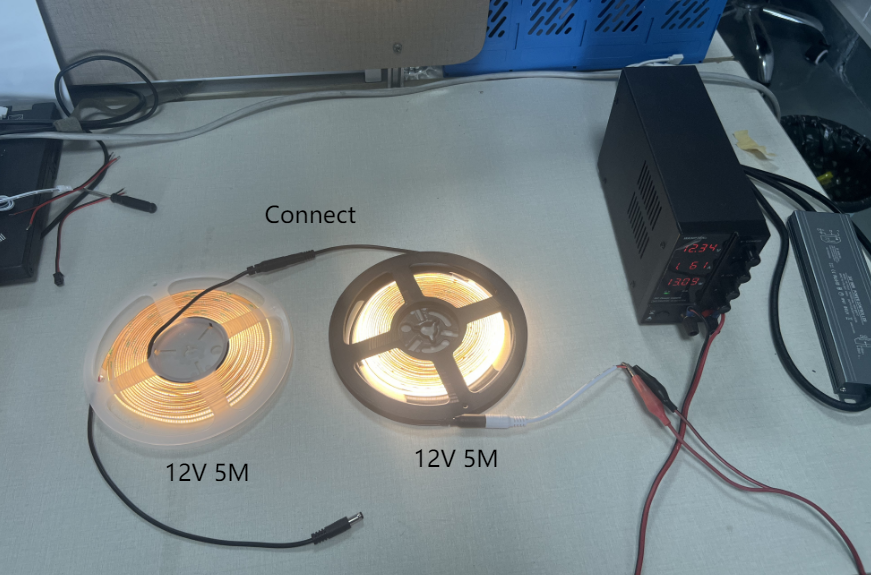

10M LED Strip Have Voltage Drop?

Controlling LED Strip Voltage Drop: Finding the Optimal Balance

Product Performance vs. Budget

(1) LED Density Affects Light Uniformity

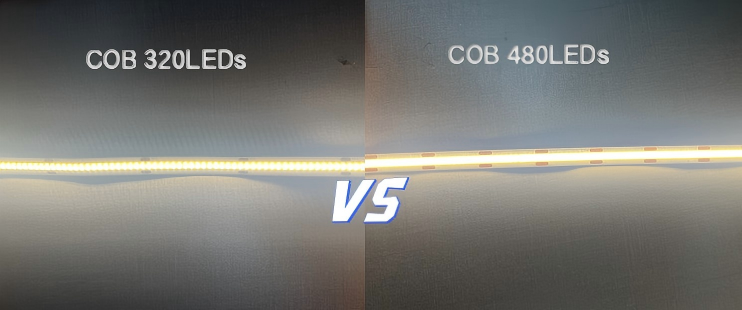

Higher LED density on a custom LED strip or custom LED strip lights ensures more even illumination. Lower-density strips may show visible light dots. For example, comparing 480-LED vs. 320-LED strips demonstrates noticeable differences. However, higher density increases power consumption, which can also lead to higher voltage drop.

(2) Power vs. Brightness

Higher power typically means brighter output, but it also increases the potential for voltage drop. Choosing the right customizable LED strips balances brightness with electrical efficiency.

(3) Designing for High Brightness or Long Runs

For projects requiring high-brightness or long custom made LED strip lights, consider increasing copper thickness, shortening each strip segment, or adding additional power input points. This ensures uniform brightness along the entire strip while minimizing voltage drop.

(4) Working Within a Budget

If budget is limited, you can optimize layout, select appropriate copper thickness, and manage series length to strike the perfect balance between performance and cost.

Product Cost-Effectiveness

(1) Choosing the Right Strip Specifications and PCB Thickness

Selecting appropriate specifications for your LED strip lights, including PCB copper thickness, helps avoid over-design and excessive costs while effectively controlling voltage drop.

(2) High-Density or High-Power LED Strips

High-density or high-power RGB LED strips may require multiple power injection points and thicker copper PCBs, which can increase costs. It’s important to balance performance with budget based on actual project needs. For example, our RGBCCT LED strips consume 16.8W while RGBW strips consume 19W. Despite adding an extra color channel, the RGBCCT has lower wattage, reflecting careful voltage drop management.

(3) Matching Power Supply and Controller

Proper pairing of power supplies and controllers for LED strip lighting reduces voltage drop issues, minimizing returns or customer complaints, and improving overall cost-effectiveness.

⚖ Need help balancing brightness, cost, and stability? Request a free consultation and let us optimize your LED strip design.

Finding Balance Through Other Design Factors

(1) Controlling Series Length

For LED strips, avoid exceeding the manufacturer’s recommended maximum series length per roll. If longer runs are needed, consider using splitters to create parallel circuits, which helps reduce voltage drop at the far end.

(2) Power Supply Design

For long runs of LED strips, adding mid-run or multi-end power injection points can effectively lower voltage drop and maintain uniform brightness.

(3) Wiring and Connectors

Use thicker wires and high-quality connectors for LED light strips to ensure low resistance and good contact, minimizing voltage drop across the circuit.

(4) LED Selection

High-density or multi-channel LEDs, require careful current distribution design to avoid low voltage at the far end.

(5) Environmental Considerations

In high-temperature environments, leave a voltage margin for LED strip manufacturers to account for resistance changes in wires or LEDs, ensuring stable operation and reducing end-of-line dimming.

LEDWorker Lighting: Controlling Voltage Drop from the Design Stage for Consistent Performance

Product Design:

At the design stage, LEDWorker Lighting leverages years to not only calculate theoretical voltage drop but also validate multiple solutions according to your actual usage scenarios.

Examples:

Depending on installation length and power distribution, we select single-end, dual-end, segmented, or looped power injection methods for LED strips to maintain uniform brightness.

Adjusting copper thickness, trace width, and layout distribution reduces line resistance, ensuring better performance for LED strip lighting

Using low-impedance, stable wires and high-performance connectors minimizes energy loss for LED light strips

For ultra-long runs of LED strips, zone-based control combined with constant-current or constant-voltage drivers guarantees uniform illumination.

Flexible selection of 12V, 24V, 48V, or other voltages balances safety and transmission efficiency, suitable for most LED strips.

Full-length voltage drop simulations and real-world testing before shipment ensure that on-site performance meets expectations for commercial installations.

By addressing voltage drop issues at the design stage and leveraging extensive project experience, our customers avoid end-of-line dimming, color shift, and other risks, achieving stable, consistent, and high-quality results with the best LED strip lights.

At LEDWorker Lighting, every design begins with your needs. Get in touch today to discuss your next LED strip project.

Tailored Voltage Drop Optimization Solutions for Different Customers

At LEDWorker Lighting, controlling voltage drop is always one of our core considerations during product design. Depending on different customer needs, we provide multiple design and technical approaches:

For Engineering Customers (Architectural & Commercial Lighting Projects): We often recommend higher-voltage LED strips (such as 36V or 48V) and optimize PCB copper thickness and trace layouts. This ensures that large-scale installations maintain uniform brightness. With LED strip manufacturers like us, projects benefit from stable and professional-grade performance.

For Retail / Finished Product Customers (Home Decoration & DIY Kits): We limit the maximum roll length during design, pair it with plug-and-play power solutions, and pre-test brightness under different lengths. This way, end users get LED strip lights that are easy to install and worry-free about voltage drop issues.

For OEM/ODM Customers (Gaming Devices, Mirrors, Home Appliances):

We collaborate with design teams to customize circuit layouts, power injection points, and connector types. The result is customizable LED light strips and custom size LED strips that are both aesthetically pleasing and easy to install, while minimizing the effects of voltage drop.

No matter the application, we don’t just deliver products — we help customers eliminate potential voltage drop issues at the design stage, ensuring consistent brightness and reliable performance throughout the lifetime of the strip.

At LEDWorker Lighting, we provide more than just high-quality LED strip lights. We focus on voltage drop control from the very beginning, ensuring every meter of strip maintains uniform brightness and stable color temperature in real-world usage. Whether for commercial projects, retail products, or OEM/ODM customization, we optimize power supply design, PCB configuration, voltage selection, and installation layout to achieve the best balance of performance, stability, and cost

Every strip light represents our commitment to quality and expertise, allowing customers to install and use them with confidence — and ultimately deliver the ideal lighting effect.

📬 Ready to eliminate voltage drop in your LED strip projects? Email us at

FAQ

Voltage drop refers to the gradual reduction of voltage as current flows through conductors and components. In LED strips, it means the LEDs closer to the power supply shine brighter, while those further away may appear dimmer.

The most common cause of voltage drop in LED strips is excessive length combined with thin copper traces. This increases resistance, leading to brightness loss at the strip’s end.

Yes, especially in low-voltage LED strips. Severe voltage drop can cause uneven brightness, color shift, flickering, or overheating. Proper design and power distribution prevent these issues.

For 12V LED strips, noticeable voltage drop may appear after 5 meters; for 24V strips, usually after 10 meters. Beyond these lengths, extra power injection points are recommended.

Voltage drop occurs in both AC and DC circuits, but it is more critical in low-voltage DC LED strips because even a small loss represents a large percentage of the supply voltage.

Voltage drop can be reduced by using higher voltage strips (24V, 48V), thicker copper PCBs, shorter runs, or multiple power injection points. Choosing quality connectors and wires also helps.

A 5% voltage drop is generally acceptable in most lighting projects. For LED strips, however, lower drop is preferred, especially for low-voltage systems (5V, 12V), to ensure brightness consistency.

Yes. Prolonged voltage drop causes LEDs at the far end to work under lower voltage, leading to uneven current distribution. This can shorten the lifespan of some LEDs and create inconsistent performance. Proper power design ensures stable operation and longer lifespan.

Higher power LED strips draw more current, which increases voltage drop along the wires and PCB traces. This is why high-brightness or high-density strips require thicker copper, shorter lengths, or multiple power feeds to balance performance.

No, voltage drop cannot be 100% eliminated, since all conductors have resistance. However, it can be minimized to a level where it does not affect performance. Using optimized PCB design, higher voltage systems, quality connectors, and proper wiring ensures the drop stays within safe limits.