LED Strip Lifespan Explained: A Complete Guide to Key Influencing Factors

On the LED strip specification sheet, you’ll often see a line like this: Operating life: 50,000 hours. At first glance, that number sounds impressive. Calculated over 365 days a year and 24 hours a day, 50,000 hours equals about 5.7 years of continuous use.

But here’s the question: if an LED strip can supposedly last that long, why do manufacturers usually offer only a 3-year or 5-year warranty? The reason is that the actual lifespan of an LED strip is affected by many factors. The figure on the spec sheet is a theoretical value—real-world results vary depending on the environment, materials, driver quality, and how the strip is used.

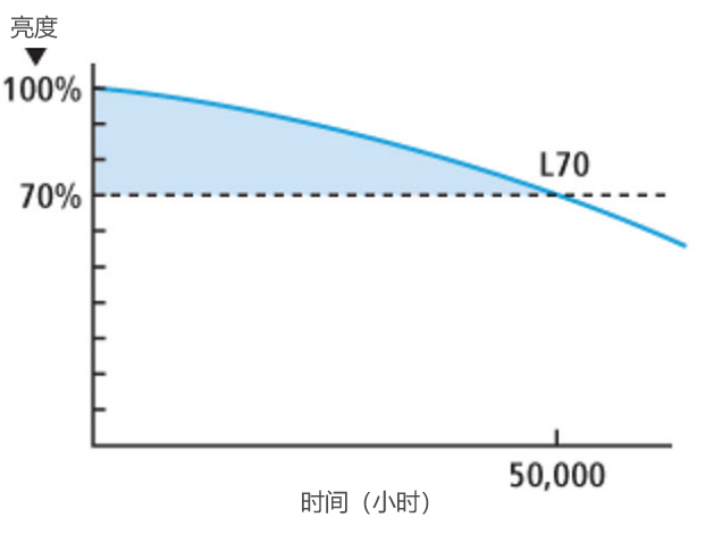

L70 Lifespan: The Industry Benchmark

In the LED industry, lifespan is typically measured by the L70 rating.

L70 indicates the amount of time it takes for a strip’s brightness to drop to 70% of its initial level. In other words, it’s the period during which the LED strip can continue operating while still maintaining sufficient brightness.

Four Key Factors Affecting LED Strip Lifespan

1.Operating Environment

The environment in which an LED strip is used plays a critical role in its lifespan.

Humid conditions:Prolonged exposure to moisture or heavy fog can cause oxidation of internal circuits and solder joints, leading to electrical damage.

High temperatures: The higher the temperature, the more heat the LEDs generate, which accelerates light decay. Excessive heat speeds up the aging of LED chips, PCB boards, and adhesive backing.

Corrosive environments: Locations such as chemical plants or coastal areas contain corrosive substances in the air that can damage strip materials and shorten service life.

Recommendation: Choose LED strips with protective ratings (such as IP65 or IP67) and select suitable encapsulation and protective designs based on the specific environment.

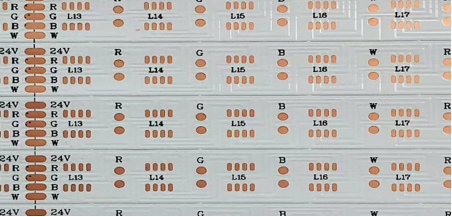

2.Manufacturing Materials

The lifespan of an LED strip depends heavily on the quality of the materials used during production.

LED chips:

High-quality chips maintain higher brightness with lower light decay. Low-grade chips tend to suffer significant brightness loss in a short time, drastically shortening lifespan.

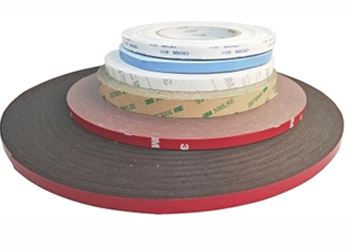

Adhesive backing:

Poor-quality adhesive can peel off easily, affecting installation stability and exposing the strip to moisture during use.

Adhesive backing:

Poor-quality adhesive can peel off easily, affecting installation stability and exposing the strip to moisture during use.

Recommendation: Choose products with guaranteed quality, and check the specification sheet for LED chip model, PCB thickness, and adhesive grade.

3.Driver Power Quality

The quality of the driver power supply is one of the most important factors affecting the lifespan of an LED strip.

Low-quality power supplies: Prone to voltage fluctuations and overheating, which can directly damage the LEDs.

Power overload: Operating the strip beyond its rated wattage causes excessive heat buildup in the LEDs, leading to a shorter lifespan.

Recommendation: Use driver power supplies from reputable brands and keep the operating load within 80% of the rated power to effectively extend the LED strip’s service life.

The lifespan of an LED strip depends not only on its quality but also on daily usage time.

2 hours per day: The strip has ample rest time, allowing heat to dissipate. Less heat buildup means slower light decay and a longer lifespan.

24 hours per day: Continuous operation leads to significant heat accumulation, faster light decay, and a shorter lifespan.

Heat vs. Light Output:

LED strips generate heat while emitting light. Heat is one of the main factors affecting light decay and overall lifespan. Even with the same specifications, different daily usage times can greatly impact service life. Long hours of operation keep the LED chip temperature consistently high, accelerating aging and reducing brightness retention.

Recommendation: For projects requiring long hours of illumination, prioritize high-quality LED chips, efficient heat-dissipation designs, and DC24V high-efficiency strips, paired with a suitable driver power supply to ensure stability and extended service life.

Real-World Case Studies

I once supplied LED strips for a European commercial space where the client chose high-quality PCBs and driver power supplies, combined with moisture protection. Three years after installation, a follow-up visit showed the strips still maintained over 90% of their original brightness. The client said this level of stability gave them great peace of mind and turned them into a long-term partner.

Another customer in the United States used LED strips to light outdoor display cabinets. They initially installed low-cost DC12V strips, but noticeable light decay appeared after just six months. Later, they switched to high-quality DC24V strips with added protection, and even after more than two years of use, brightness loss remained minimal—dramatically extending the project’s lifespan.

My Expert Advice

Based on my 20 years of LED industry experience, I recommend that customers look beyond the L70 rating when choosing LED strips. Pay close attention to overall product quality, suitability for the operating environment, and planned daily usage time. Under normal conditions, high-quality LED strips typically last well beyond their warranty period.

REQUEST A QUOTE

If you’re looking for longer-lasting, more stable LED strips for your project, feel free to contact us today.

We provide professional product recommendations, customized solutions, and high-quality LED strips to ensure your project maintains its ideal performance over time.

👉 Get in touch now → [Click here to contact us]

📩 Or email us at: