A Comprehensive Guide to LED Strip Production Process and Quality Insights

Introduction to LED Strips

LED strips have revolutionized the lighting industry with their energy efficiency, vibrant colors, and versatility. From architectural lighting to home décor, LED strips cater to diverse applications. This blog delves into the intricate production processes of LED strips and highlights essential quality aspects, helping buyers and industry professionals make informed decisions.

Understanding LED Strip Categoris

- Material: Made with FPC boards and SMD LEDs.

- Applications: Perfect for tight spaces and creative designs due to their flexibility.

- Key Feature: Easily customizable and available in various LED densities, such as 30, 60, 120 LEDs per meter.

- Material: LEDs are mounted directly onto the PCB and encapsulated with phosphor-infused glue.

- Applications: Ideal for creating uniform, linear lighting effects without visible hotspots.

- Key Feature: Superior brightness, better heat dissipation, and extended lifespan.

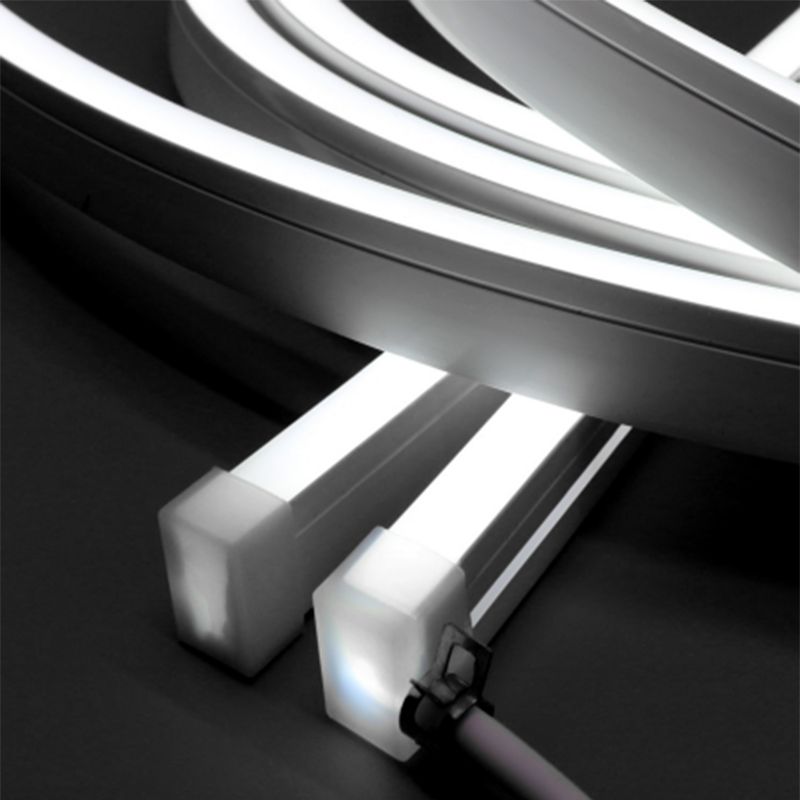

- Material: Encased in silicone sleeves for waterproofing and durability.

- Applications: Popular in outdoor signage, architectural contours, and decorative elements.

- Key Feature: Excellent light diffusion and shock resist

Key Steps in LED Strip Manufacturing

1. Preparation:

-

Verify voltage requirements (5V, 12V, or 24V).

-

Test LED VF values and prepare components like resistors and capacitors.

2. Solder Paste Printing:

-

Apply solder paste evenly onto PCB pads using automated printers.

-

Inspect for even coverage to avoid future quality issues.

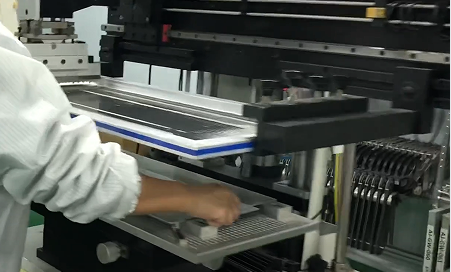

3. SMT Placement:

-

Place FPC boards in SMT machines to attach LEDs and other components.

-

Ensure proper alignment and polarity during the process.

4. Reflow Soldering:

-

Bake PCB boards to melt solder paste and secure components.

-

Control temperature to prevent defects like cold soldering or warping.

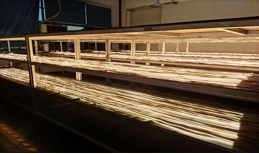

5. Aging and Testing:

-

Perform aging tests by powering strips continuously for several hours.

-

Inspect for brightness consistency and electrical performance.

6. Glue Application (for Waterproofing):

-

Apply silicone or polyurethane glue to ensure durability and water resistance.

-

Use vacuum degassing to eliminate air bubbles for a smooth finish.

7. Packaging:

-

Bundle strips in protective packaging with clear labels.

-

Ensure safe and efficient transport to maintain quality.

Below are some related videos

Common Quality Challenges and Solutions

-

Color Temperature Inconsistency:

-

Issue: Mixed color temperatures within a single strip (e.g., 3000K and 6500K).

-

Solution: Implement strict QC processes during production to segregate LEDs by batch.

-

-

Premature LED Failure:

-

Issue: Dead LEDs after a short usage period due to overheating.

-

Solution: Use larger LED chips and optimize PCB design for better heat dissipation.

-

-

Glue Discoloration:

-

Issue: Yellowing or cracking of glue after exposure to UV light.

-

Solution: Opt for high-quality silicone or polyurethane glue with UV resistance.

-

-

Adhesive Issues:

-

Issue: Use of counterfeit 3M adhesives causing strips to detach.

-

Solution: Source genuine 3M adhesives, such as 9080A or VHB, known for reliability.

-

Best Practices for LED Strip Selection

-

Evaluate Specifications:

-

Check brightness levels (lumens per watt) and power consumption.

-

Ensure the product meets environmental requirements like waterproof ratings (IP20, IP65).

-

-

Inspect Certifications:

-

Look for CE, RoHS, and other relevant certifications for safety and quality assurance.

-

3. Verify Supplier Credibility:

-

-

Research supplier history and customer reviews.

-

Ensure the supplier offers warranty support and adheres to international trade standards.

-

Conclusion

Choosing high-quality LED strips requires an understanding of production processes, quality standards, and common pitfalls. By partnering with experienced manufacturers and verifying key product attributes, buyers can ensure long-lasting and efficient lighting solutions. If you’re looking for reliable LED strip products, feel free to contact us for expert guidance and superior service.

Keywords:

LED strip production, SMD LED strips, COB LED strips, neon LED strips, LED manufacturing process, LED quality control, LED strip aging test, waterproof LED strips, LED adhesive solutions, LED supplier verification, energy-efficient lighting solutions.

Ensure your next lighting project shines brighter with expertly crafted LED strips tailored to your needs!

Phone:+8613420963227

Email:

WhatApp:https://wa.me/8613420963227